SS4- Diagnosing and servicing tires

advertisement

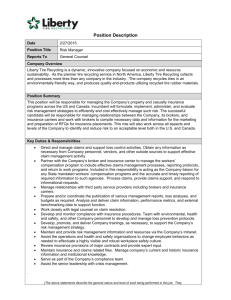

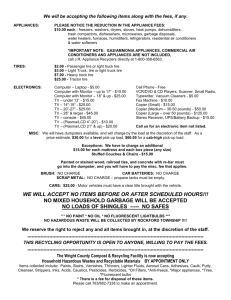

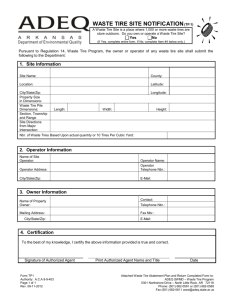

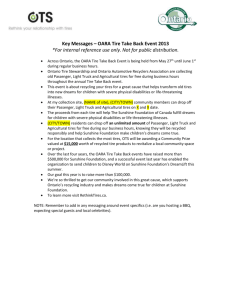

SS4- DIAGNOSING AND REPAIRING TIRES Name_________________________ Description: During this lesson you will learn and become familiar with the automotive tire. Diagnosis and service procedures such as how to properly change and balance tires and wheels as well as, understanding abnormal tire wear patterns and what causes them. You will also become familiar with TPMS (tire pressure monitoring systems) as well. Reading Tire Information: All vehicle tires have very important information printed on the side wall of the tire. This information can tell you the speed rating, tire pressure specification, weather rating such as snow or all-season, and also the tires thickness or plies. An example is below A speed and load chart to help you identify your tires data On 3 shop vehicle tires, locate and find the following information Width of tire _____________________ Aspect Ratio ____________________ Diameter of wheel __________________ Load Rating ____________________ Speed Rating _________________________ Recommended Tire Pressure ________________ Tread wear rating ____________________ Width of tire _____________________ Aspect Ratio ____________________ Diameter of wheel __________________ Load Rating ____________________ Speed Rating _________________________ Recommended Tire Pressure ________________ Tread wear rating ____________________ Width of tire _____________________ Aspect Ratio ____________________ Diameter of wheel __________________ Load Rating ____________________ Speed Rating _________________________ Recommended Tire Pressure ________________ Tread wear rating ____________________ Identifying Tire Wear Patterns and Causes Below are some tires that have worn abnormal. I want you to review these and find three tires in the shop with wear on them. Identify each to the instructor Tire #1 ___________________________________________ Tire #2 ___________________________________________ Tire #3 ___________________________________________ Instructor Ok ______________________________ Removing a tire from the wheel Have instructor demonstrate how to remove a tire from the wheel Now you will remove a tire and install one by yourself Instructor OK ________________________________ Tire Balance Tire balancing compensates for the weight of the tire and wheel assembly after the tire is mounted. A wheel is out of balance when one area is heavier or lighter than the rest. The result? Bouncing or wobbling, which can decrease treadwear, increase vibration and cause stress on your vehicle. The cure? Correction weights are added to counterbalance the tires. When to Balance A tire is replaced A balance weight is moved or removed You purchase new tires How Wheels are Balanced To balance a wheel, a balancing machine is used to determine where the heavy spots are. Weights are then attached to the exterior or interior of the wheel to counteract centrifugal forces acting on the heavy areas when the wheel is turning. This will eliminate vertical bouncing and side-to-side wobble. Static and Dynamic Unbalance Have the instructor demonstrate how to balance a tire and wheel Complete the procedure now by yourself Instructor OK ______________________________ Rotating Tires Rotating your tires as part of your regularly scheduled vehicle maintenance has many benefits. It helps to maintain an even amount of treadwear on all 4 tires. That prolongs the life of your tires, leads to improved gas mileage and a smoother more comfortable ride. Regularly rotating your tires can also prolong the life of your vehicle’s suspension components by reducing vibrations. Since you need to remove the wheels to rotate your tires, you get the opportunity to look over the undercarriage components and catch any problems in the very early stages which can save you money down the road. Also, many tire manufacturers require regular tire rotation in order to keep the mileage warranty valid. A good rule of thumb is to rotate your tires at the same intervals you get your oil changed whether your tires show uneven wear signs or not. While this is a good recommendation, you should always follow the guidelines in your vehicle’s owner manual for timing as well as the best rotation pattern for your vehicle and type of tires. Locate a shop vehicle to perform a tire rotation on and complete the tasks Instructor OK ________________________________ Tire Pressure Monitoring Systems Direct Monitoring Systems Direct tire pressure monitoring systems measure, identify and warn the driver of low pressure. Because direct systems have a sensor in each wheel, they generate accurate warnings and can alert the driver instantly if the pressure in any one tire falls below a predetermined level due to rapid air loss caused by a puncture. In addition, direct tire pressure monitoring systems can detect gradual air loss over time. Some direct systems use dashboard displays that provide the ability to check current tire pressures from the driver's seat. Direct systems attach a pressure sensor/transmitter to the vehicle's wheel inside the tire's air chamber. Most Original Equipment and some aftermarket systems attach their air pressure sensor/transmitter to special tire valves. While the presence of a metal clamp-in valve typically identifies the presence of a direct tire pressure monitoring system, special snap-in rubber valves have also been used to support direct system sensors. The transmitter's signal is broadcast to the in-car receiver and the information is displayed to the driver. Some aftermarket and Original Equipment direct monitoring systems attach the sensor/transmitter to the wheel with an adjustable metal strap. These sensors/transmitters and their straps only weight a few ounces and allow virtually universal application on car and light truck wheels. Since standard snap-in rubber valves are still used for these applications, it is important that the owners of these systems let their tire installer know that the vehicle is equipped with a direct system banded to the wheel before they change the tires. Tire Rack works with wheel manufacturers to develop aftermarket wheels that accommodate direct tire pressure monitoring sensors/transmitters. This results in our ability to offer a wider selection of aftermarket alloy wheel styles that accept Original Equipment direct system components. Additionally, the Tire Rack's fitment specialists have carefully determined which aftermarket wheels will be compatible with the vehicle and system installed for customers purchasing Tire & Wheel Packages or wheel upgrades. Search results include notes regarding TPMS sensors and sensors can confidently be purchased online with wheels. Indirect Monitoring Systems In the interest of providing a lower cost Original Equipment system, indirect tire pressure monitoring systems were developed by vehicle manufacturers wishing to comply with the law while minimizing development time and cost. Indirect systems use the vehicle's antilock braking system's wheel speed sensors to compare the rotational speed of one tire to that in another position on the vehicle. If one tire is low on pressure, its circumference changes enough to roll at a slightly different number of revolutions per mile than the other three tires. Reading the same signal used to support ABS systems, the vehicle manufacturers have programmed another function into the vehicle's onboard computer to warn the driver when a single tire is running at a reduced inflation pressure compared to the others. Unfortunately, indirect tire pressure monitoring systems have several shortcomings. Indirect systems won't tell the drivers which tire is low on pressure, and won't warn the driver if all four tires are losing pressure at the same rate (as occurs during the fall and winter months when ambient temperatures get colder). Additionally, our current experience with indirect systems indicates that they can generate frequent false warnings. We have found that false warnings may occur when the tires spin on wet, icy and snow-covered roads. In these cases, the false alarms would train the driver to disregard the tire pressure monitoring system's warnings, negating its purpose completely. Caution: 1. Before removing a tire from a TPMS equipped rim, be sure to take extra care not to break the sensor inside the wheel, this is easily done, trust me!!!! 2. TPMS may need to be re-learned or programmed after a tire rotation so follow the manufacturer’s specifications for proper re-learn ASE Questions: 1. Tire size information can be found on a sticker located on the driver’s door called a __________________________ 2. A tire speed rating of “H” would indicate ___________________________ 3. In comparison of a “100”wear indexed tire to a “200” wear indexed tire, the “200” load tire will last __________________ as long as the “100” wear tire 4. A _____________________ provides a means of installing or removing a tire from the wheel. 5. Explain hub centric and lug centric wheels _____________________________________________________________ _____________________________________________________________ _____________________________________________________________ 6. When checking a hot tire that calls for, “35 lbs of air” how much air should be added or put into the tire. 7. Explain wheel tramp, the type of wear it causes, and what causes wheel tramp. _____________________________________________________________ _____________________________________________________________ _____________________________________________________________ 8. Slight indentations on a tire side wall are ______________________. 9. Some tires are designed to be run in ________________ direction. 10. Tire Runout can be either _________________ or __________________. 11. Out of round tires can be __________________ but will still cause _____________________. 12. What is tire and wheel matching and why is it necessary sometimes? _____________________________________________________________ _____________________________________________________________