5536

advertisement

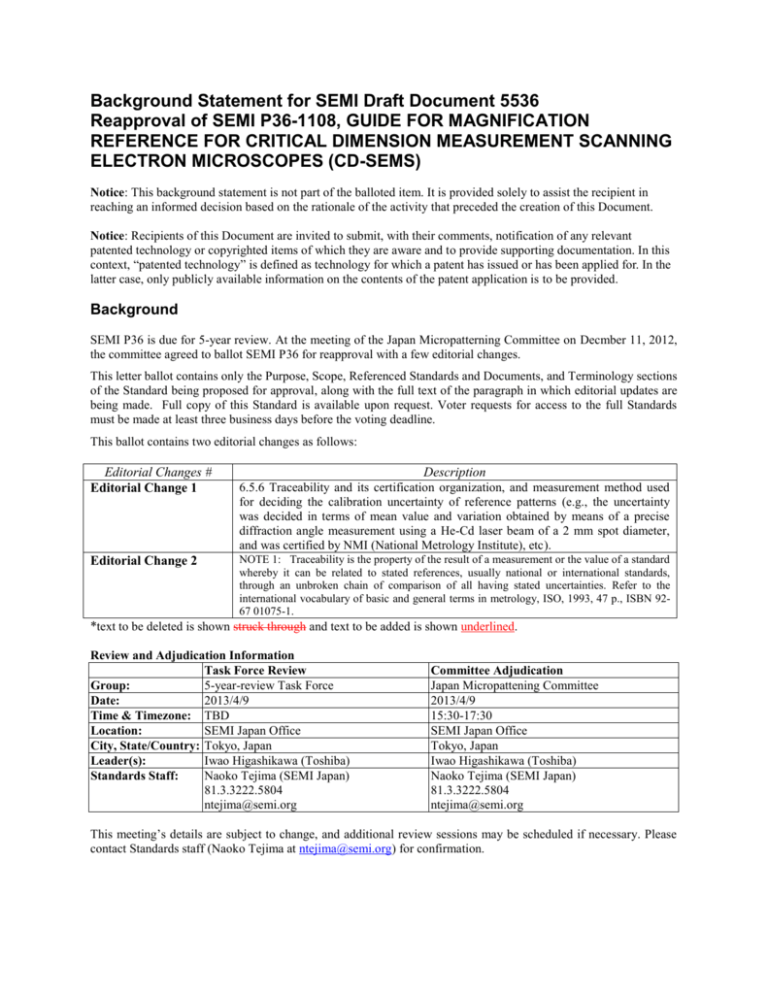

Background Statement for SEMI Draft Document 5536 Reapproval of SEMI P36-1108, GUIDE FOR MAGNIFICATION REFERENCE FOR CRITICAL DIMENSION MEASUREMENT SCANNING ELECTRON MICROSCOPES (CD-SEMS) Notice: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this Document. Notice: Recipients of this Document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided. Background SEMI P36 is due for 5-year review. At the meeting of the Japan Micropatterning Committee on Decmber 11, 2012, the committee agreed to ballot SEMI P36 for reapproval with a few editorial changes. This letter ballot contains only the Purpose, Scope, Referenced Standards and Documents, and Terminology sections of the Standard being proposed for approval, along with the full text of the paragraph in which editorial updates are being made. Full copy of this Standard is available upon request. Voter requests for access to the full Standards must be made at least three business days before the voting deadline. This ballot contains two editorial changes as follows: Editorial Changes # Editorial Change 1 Editorial Change 2 Description 6.5.6 Traceability and its certification organization, and measurement method used for deciding the calibration uncertainty of reference patterns (e.g., the uncertainty was decided in terms of mean value and variation obtained by means of a precise diffraction angle measurement using a He-Cd laser beam of a 2 mm spot diameter, and was certified by NMI (National Metrology Institute), etc). NOTE 1: Traceability is the property of the result of a measurement or the value of a standard whereby it can be related to stated references, usually national or international standards, through an unbroken chain of comparison of all having stated uncertainties. Refer to the international vocabulary of basic and general terms in metrology, ISO, 1993, 47 p., ISBN 9267 01075-1. *text to be deleted is shown struck through and text to be added is shown underlined. Review and Adjudication Information Task Force Review 5-year-review Task Force Group: 2013/4/9 Date: Time & Timezone: TBD SEMI Japan Office Location: City, State/Country: Tokyo, Japan Iwao Higashikawa (Toshiba) Leader(s): Naoko Tejima (SEMI Japan) Standards Staff: 81.3.3222.5804 ntejima@semi.org Committee Adjudication Japan Micropattening Committee 2013/4/9 15:30-17:30 SEMI Japan Office Tokyo, Japan Iwao Higashikawa (Toshiba) Naoko Tejima (SEMI Japan) 81.3.3222.5804 ntejima@semi.org This meeting’s details are subject to change, and additional review sessions may be scheduled if necessary. Please contact Standards staff (Naoko Tejima at ntejima@semi.org) for confirmation. Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 SEMI Draft Document 5536 Reapproval of SEMI P36-1108, GUIDE FOR MAGNIFICATION REFERENCE FOR CRITICAL DIMENSION MEASUREMENT SCANNING ELECTRON MICROSCOPES (CD-SEMS) 1 Purpose 1.1 The purpose of this guide is (1) to define common and important specifications of magnification references which are used for calibrating magnifications of critical dimension measurement scanning electron microscopes (CD-SEMs), and as the result (2) to provide magnification references which are easy for anyone to use. 2 Scope 2.1 It is preferable that design, manufacture and purchase specifications for CD-SEM magnification references conform to this guideline. NOTICE: This standard does not purport to address safety issues, if any, associated with its use. It is the responsibility of the users of this standard to establish appropriate safety and health practices and determine the applicability of regulatory or other limitations prior to use. 3 Referenced Standards and Documents 3.1 None. 4 Terminology 4.1 Definitions 4.1.1 CD-SEM magnification reference — a CD-SEM magnification reference is defined as a standard for calibrating magnifications of a said CD-SEM through mounting the standard on the specimen stage, measuring the dimensions of reference patterns formed on the standard, determining the difference between the measurement value and the true or reference value of the reference patterns, and adjusting the CD-SEM parameters to bring the difference zero. 4.1.1.1 There are two types of CD-SEM magnification references: one is a wafer on which reference patterns are formed; another is a chip on which reference patterns are formed. Hereinafter, the former will be referred to as “wafer-type magnification reference,” and the latter will be referred to as “chip-type magnification reference.” 4.1.2 edge roughness — edge roughness refers to edge variations seen in the SEM images, and is defined as the distance, within a field of view, between the peak line and the valley line, where the peak line means the line which runs through the highest peak and is parallel to the pattern-edge mean line, the valley line means the line which runs through the lowest valley and is parallel to the pattern-edge mean line, and the pattern-edge mean line conforms to the expected pattern-edge line. Here, a peak is the tip of a convex section, and a valley is the deepest part of a concave section. 5 Ordering Information 5.1 None. 6 Requirements 6.5.6 Traceability and its certification organization, and measurement method used for deciding the calibration uncertainty of reference patterns (e.g., the uncertainty was decided in terms of mean value and variation obtained by means of a precise diffraction angle measurement using a He-Cd laser beam of a 2 mm spot diameter, and was certified by NMI (National Metrology Institute), etc). NOTE 1 Traceability is the property of the result of a measurement or the value of a standard whereby it can be related to stated references, usually national or international standards, through an unbroken chain of comparison of all having stated uncertainties. Refer to the international vocabulary of basic and general terms in metrology, ISO, 1993, 47 p., ISBN 92-67 01075-1. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 2 Doc. 5536 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5536 Date: 2/9/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 NOTICE: Semiconductor Equipment and Materials International (SEMI) makes no warranties or representations as to the suitability of the Standards and Safety Guidelines set forth herein for any particular application. The determination of the suitability of the Standard or Safety Guideline is solely the responsibility of the user. Users are cautioned to refer to manufacturer’s instructions, product labels, product data sheets, and other relevant literature, respecting any materials or equipment mentioned herein. Standards and Safety Guidelines are subject to change without notice. By publication of this Standard or Safety Guideline, SEMI takes no position respecting the validity of any patent rights or copyrights asserted in connection with any items mentioned in this Standard or Safety Guideline. Users of this Standard or Safety Guideline are expressly advised that determination of any such patent rights or copyrights, and the risk of infringement of such rights are entirely their own responsibility. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 3 Doc. 5536 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5536 Date: 2/9/2016