5754

advertisement

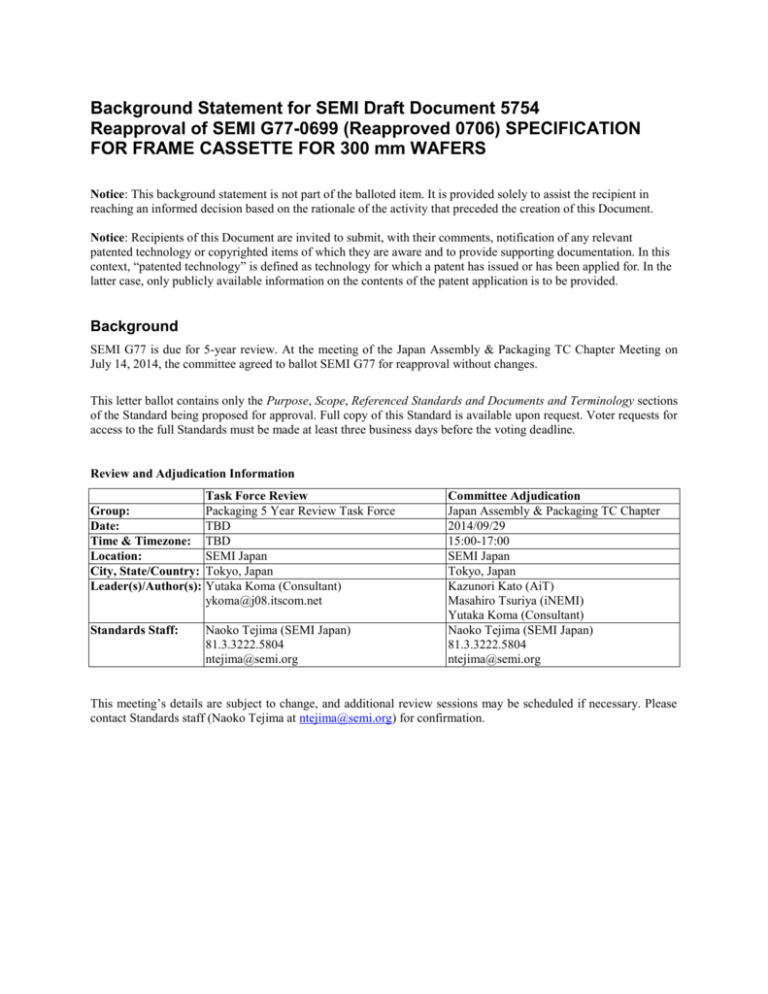

Background Statement for SEMI Draft Document 5754 Reapproval of SEMI G77-0699 (Reapproved 0706) SPECIFICATION FOR FRAME CASSETTE FOR 300 mm WAFERS Notice: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this Document. Notice: Recipients of this Document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided. Background SEMI G77 is due for 5-year review. At the meeting of the Japan Assembly & Packaging TC Chapter Meeting on July 14, 2014, the committee agreed to ballot SEMI G77 for reapproval without changes. This letter ballot contains only the Purpose, Scope, Referenced Standards and Documents and Terminology sections of the Standard being proposed for approval. Full copy of this Standard is available upon request. Voter requests for access to the full Standards must be made at least three business days before the voting deadline. Review and Adjudication Information Group: Date: Time & Timezone: Location: City, State/Country: Leader(s)/Author(s): Standards Staff: Task Force Review Packaging 5 Year Review Task Force TBD TBD SEMI Japan Tokyo, Japan Yutaka Koma (Consultant) ykoma@j08.itscom.net Naoko Tejima (SEMI Japan) 81.3.3222.5804 ntejima@semi.org Committee Adjudication Japan Assembly & Packaging TC Chapter 2014/09/29 15:00-17:00 SEMI Japan Tokyo, Japan Kazunori Kato (AiT) Masahiro Tsuriya (iNEMI) Yutaka Koma (Consultant) Naoko Tejima (SEMI Japan) 81.3.3222.5804 ntejima@semi.org This meeting’s details are subject to change, and additional review sessions may be scheduled if necessary. Please contact Standards staff (Naoko Tejima at ntejima@semi.org) for confirmation. Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 DRAFT SEMI Draft Document 5754 Reapproval of SEMI G77-0699 (Reapproved 0706) SPECIFICATION FOR FRAME CASSETTE FOR 300 mm WAFERS 1 Purpose 1.1 The purpose of this document is to specify the mechanical features for a 300 mm wafer frame cassette used between the wafer mounting process and the die-bonding process. 2 Scope 2.1 This standard is intended to set an appropriate level of specification that places minimal limits on innovation while ensuring modularity and interchangeability at all mechanical interfaces. 2.2 Only the physical interfaces for the frame cassette are specified; no materials requirements or microcontamination limits are given. However, this specification was written to allow for both metal and plastic frame cassette designs. 2.3 This specification defines a 300 mm wafer frame cassette that is intended for both manual and automated transport. The frame cassette has the following components and sub-components (“” indicates an optional component): 2.3.1 Top - robotic handling flange (optional) top cover 2.3.2 Interior - frame supports for 13 or 25 tape frames - frame restraint 2.3.3 Sides human handles (optional) 2.3.4 Rear - rear cover 2.3.5 Bottom - 2 bottom conveyor rails running along the sides of the frame cassette 3 features that mate with kinematic coupling pins and provide a 10 mm lead-in (optional) 4 frame cassette sending pads (optional) NOTICE: This standard does not purport to address safety issues, if any, associated with its use. It is the responsibility of the users of this standard to establish appropriate safety and health practices and determine the applicability of regulatory or other limitations prior to use. 3 Referenced Standards and Documents 3.1 SEMI Standards SEMI E1.9 Provisional Mechanical Specification for Cassettes Used to Transport and Store 300 mm Wafers SEMI E15 Specification for Tool Load Port SEMI E47.1 Provisional Mechanical Specification for Boxes and Pods Used to Transport and Store 300 mm Wafers SEMI E57 Provisional Mechanical Specification for Kinematic Couplings Used to Align and Support 300 mm Wafer Carriers SEMI G74 Specification for Tape Frame for 300 mm Wafers This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 1 Doc. 5754 SEMI LETTER (YELLOW) BALLOT Document Number: 5754 Date: 3/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 DRAFT SEMI S8 Safety Guidelines for Ergonomics/Human Factors Engineering of Semiconductor Manufacturing Equipment NOTICE: Unless otherwise indicated, all documents cited shall be the latest published versions. 4 Terminology 4.1 bilaterial datum plane a vertical plane that bisects the tape frames and that is perpendicular to both the horizontal and facial datum planes (as defined in SEMI E57). 4.2 conveyor rails parallel surfaces on the bottom of the cassette for supporting the cassette on roller conveyors. 4.3 facial datum plane a vertical plane that bisects the tape frames and that is parallel to the front side of the frame cassette (where tape frames are removed or inserted). On tool load ports, it is also parallel to the load face plane specified in SEMI E15 on the side of the tool where the frame cassette is loaded and unloaded (as defined in SEMI E57). 4.4 frame cassette an open structure that holds one or more tape frames. 4.5 horizontal datum plane a horizontal plane from which projects the kinematic coupling pins on which the frame cassette sits. On tool load ports, it is at the load height specified in SEMI E15 and might not be physically realized as a surface (as defined in SEMI E57). 4.6 robotic handling flange horizontal projection on the top of the frame cassette for lifting and rotating the frame cassette. 4.7 tape frame the frame which applies the wafer tape to the wafer and retains the wafer. 4.8 wafer tape an adhesive plastic tape which retains the wafer or diced chip. It is used between the mounting process and die-bonding process. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 2 Doc. 5754 SEMI LETTER (YELLOW) BALLOT Document Number: 5754 Date: 3/12/2016