CHML212

advertisement

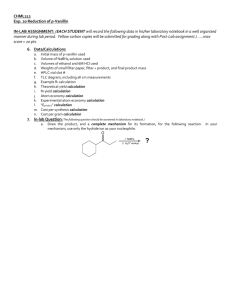

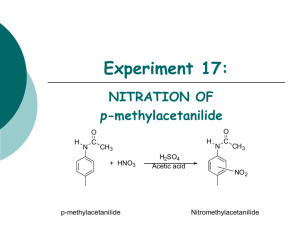

CHML212 Exp. 17 Nitration of p-methylacetanilide IN-LAB ASSIGNMENT: (EACH STUDENT will record the following data in his/her laboratory notebook in a well organized manner during lab period. Yellow carbon copies will be submitted for grading along with Post-Lab assignment.) …..max score = 20 pts. 6. Data/Calculations a. b. c. d. e. f. g. h. i. j. k. l. m. n. o. p. Initial weight of p-methylacetanilide HPLC vial slot #s (should have 3) Theoretical yield calculation (not just value!) Volume of 90:10 ethanol/water used for recrystallization Weight of small & LARGE filter paper Weight of small filter + large filter + recrystallized dry product Weight of recrystallized dry product Physical state and color of product TLC diagram Example TLC Rf value calculation (not just value!) Experimental melting point range Atom economy calculation (not just value!) Experimental atom economy calculation (not just value!) “Eproduct” calculation (not just value!) Cost per synthesis calculation (not just value!) Cost per gram calculation (not just value!) 7. In-lab Question (The following question should be answered in laboratory notebook.) a. Upon comparison of the 1H-NMR spectra of reactant and major product (p. 147 in lab manual), the most noticeable changes were observed in the aromatic region. Based on the symmetry of the reactant and product molecules, briefly explain why these changes occur. CHML212 Exp. 17 Nitration of p-methylacetanilide POST-LAB ASSIGNMENT: (EACH LAB GROUP will submit one copy of a typewritten, paragraph style report addressing all of the points listed below. Must be written using PAST TENSE, PASSIVE VOICE. ) …..max score = 50 pts. 8. Experimental (Write 1-2 paragraphs including all of the following. Do NOT present a bulleted outline.) What type of reaction did you perform? Describe the actual synthetic procedure. Include names of any reactants used and desired product, as well as name of solvent and catalyst used (if any). Be sure to give actual volumes/masses of compounds used during the synthesis (not just what the lab manual tells you to use). Describe the purification technique used to isolate the desired product, including names and actual volume/mass of any compound used during purification. Describe the analytical technique used to evaluate the product, including actual names and actual volume/mass of any compound used during sample preparation. 9. Results (Cut and paste completed tables into your document.) Table 17.1 Experimental results Theoretical yield (g) Actual yield (g) Percent yield Experimental melting range (oC) Product appearance Table 17.2 Green chemistry results Atom Economy (%) Experimental Atom Economy (%) “Eproduct” Cost per Synthesis ($) Cost per Gram ($/g) Table 17.3 TLC results Compound Standards TLC Rf values Crude Filtrate sample sample Recrystallized sample p-methylacetanilide 4-methyl-2-nitroacetanilide 4-methyl-3-nitroacetanilide Table 17.4 HPLC results Standards Compound Retention Times (min) CRUDE Retention Area Times Percent (min) Sample FILTRATE Retention Area Times Percent (min) RECRYSTALLIZED Retention Area Times Percent (min) p-methylacetanilide 4-methyl-2-nitroacetanilide 4-methyl-3-nitroacetanilide 10. Discussion (Write 1-2 paragraphs including the following.) Does the recrystallized product appear to be pure based on melting point analysis? Justify this statement by including literature and experimental melting points of the major product. Does the recrystallized product appear to be pure based on TLC analysis? Justify the statement by including actual Rf values of all standards and any compounds in your sample lane. Does the recrystallized product appear to be pure based on HPLC analysis? Justify the statement by including actual Rt values of any compound in standard and in your sample chromatogram. Is the purity based on TLC and HPLC analyses consistent with the results from melting point analysis? If not, provided a brief explanation for the inconsistency. Based on the HPLC chromatogram of your liquid filtrate, does it appear that all of the reactant had been converted to product? Do these results indicate any source of possible product loss? Include a short comment addressing what could be done differently to improve the experimental results, if repeated. Be sure to attach all HPLC chromatograms!