DigiFin Poster

advertisement

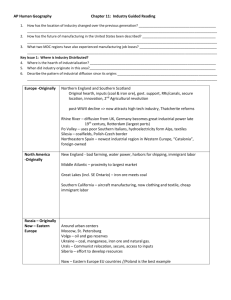

DIGIFIN DIGItal finishing improving performance of the textile FINishing industry ECO/11/304431 The DIGIFIN project intends to reduce the energy and raw material usage in textile finishing industry by using Ink Jet technology and at the same time proving the reliability and economic feasibility of this enabling technology. There are a number of ways Ink Jet technology will contribute to a significantly lower carbon footprint of textile industry. ENVIRONMENTAL OBJECTIVES Waste reduction through mass customization. Mass customization reduces the amount of waste because orders are made to customers’ requirements and needs. In this way obsolete stock will be something from the past. Ink Jet technology makes it possible to create a different product set-up with the same or even better performance. Because of this different set-up the machine down time, switching between settings and different chemicals can be minimized. Obviously this leads to less waste and a higher efficiency usage of energy. Traditional textile processes use a large quantity of water to transport chemicals to those spots on and in the textile where these chemicals are required. This large amount of water must be evaporated before further processing is possible. Evaporation of water is a energy consuming process. Ink Jet technology is an intrinsic different process of applying chemicals without the necessity to use large amounts of water for transportation. OBJECTIVES Reduction of energy usage Reduction of stock left-over Reduction of production related waste Reduction of water usage Flexibility of production (making mass customisation possible) Coordinator contact details: Mr. Gerrit Koele (TenCate Protect B.V.) Tel.: +31 548 633 668 Mob.: +31 6 1311 0777 E-mail: g.koele@tencate.com WWW.DIGIFIN.EU