Project Information Sheet #1

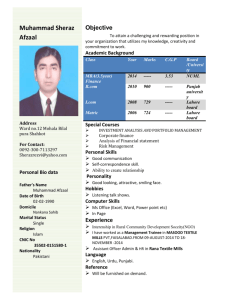

advertisement

Project Information Sheet #1 Project full name DIGIFIN N° ECO/11/304431: DIGItal finishing with High Speed Ink-Jet technology, significantly improving sustainability, flexibility and economic performance of the textile FINishing industry. Programme area: Green Business Textile industry, Depositing / Application of chemicals on textile substrates Coordinator: Gerrit Koele TenCate Protect B.V., The Netherlands E-mail: g.koele@koelemanagement.com. Tel. +31 548 633 668 Mob.: +31 6 1311 0777 Antonino Tricomi Reggiani macchine S.P.A , Italy E-mail: antonino.tricomi@reggianimacchine.it Tel. +39 (0)35 3844 511 Mob.: +39 335 8612 0818 www.digifin.eu (under construction) Partners: Website: Benefits : Reduction of environmental impact Improved economical performance due to new product potential Mass customisation route Sun Awning Keywords: Sector: Type of solution 1. Reduction raw material and energy consumption 2. Production flexibility 3. New product possibilities Green Business Product, process, technology Duration: Budget: Contract number: 14/07/2012 – 13/07/2015 Total € 3,291,465 of which EU contribution € 1.020,000 ECO/11/304431 Summary The textile industry is on the eve of one of the biggest breakthroughs since the industrial revolution. The present project is one of the essential steps in realizing this breakthrough. Traditionally a generous amount of chemicals is applied in textile industry using an excessive amount of water as carrier for these chemicals. By joining forces Reggiani, a well-known textile machine supplier, and TenCate Protect, a renowned textile finishing company, will make this step to industrialization happen. The goal of the current project is to show the technical and industrial reliability of ink jet technology for economically feasible applications. The first step is to show the world that ink jet is a technology reliable in industrial settings outperforming the traditional processes from both technical and economical point. During the first phase the principle and reliability will be proven by means of applying a coloured design to textile substrates. The next step, applying functional chemistry besides colouring, will be engineered simultaneously. This latter phase differs in machine set up and handling from the first application. Expected and/or achieved results Expected results: 1. 2. 3. Reduction of environmental impact (energy and raw material usage) by means of ink jet technology for high performing products. Comparison between the new enabling technology and the current traditional technologies results in a significantly reduced water usage, chemical usage, solid waste, energy usage and waste water production. Reduction potential varying from 50 to 80 %. Demonstration of technical reliability of ink jet technology for Sun Awning application. Ink Jet technology Prove of economical feasibility through test production. July 2012 Page 1 4. Offering new product ranges not possible with traditional technologies. The new technology offers 5. possibilities currently only possible against, unacceptable, high costs and waste production. The technology offers the possibility to create products with a different product set-up and with that the possibility to produce cost effectively and environmental friendly. Route to Mass customization. This route stops the production of superfluous products because only the product and quantity desired by the customer will be produced. In this way obsolete stock, becoming waste, is prevented. July 2012 Page 2