Special solutions textile / fibres-yarns Lenzing AG: Mandate extends

advertisement

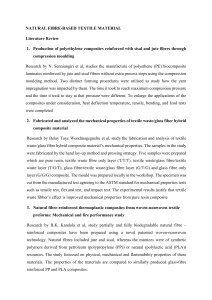

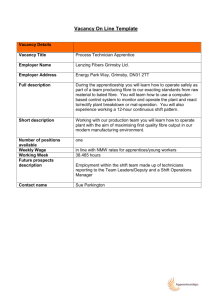

textile / fibres-yarns 70 years of experience Special solutions The V. Fraas GmbH, Helm­brechts (D), traditional company, founded 130 years ago and known as market leader in the field of textile accessories, came with special solutions for different technical applications und works in cooperation with RWTH Aachen (D) and TU Dresden (D). The membership in the Tudalit brand association ensures that the company are always up to date when it comes to ”textile re- 3D-simulation technology This results in highly sophisticated textile structures for individual applications in high-end compound materials boasting enormous carrying capacity and very low self weight. All high-capacity thread materials (e.g. carbon, aramid, glass, basalt, metals, ceramics) as well as natural and synthetic fibres can be used. The knitted materials are used e.g. as re- Photo: V. Fraas Lenzing caters to the worldwide textile and nonwoven industry – from vintage viscose through Modal right up to lyocell fibres – and has become established as the leading supplier in numerous business-to-business markets. With an annual turnover of EUR 1.26 million (2007) and a fibre production volume of 523,000 tonnes, 86% of sales are to customers outside of Austria. Lenzing has 70 years of experience under its belt in fibre production and employs 5,775 members of staff worldwide. Although the global recession made itself be felt in the first six months of 2009, the Lenzing Group managed to chalk up a clearly positive balance in the second quarter of 2009, with an accounting income of 11.3 million euros (after having incurred a loss of 5.4 million euros in the first quarter of 2009). As compared to the same period of the previous year, consolidated sales in the first half of 2009 declined by 14.4% from 689.5 to 589.9 million euros. However, turnover and revenues are anticipated to stabilise to some degree. Obvious reasons for this are the positive volume demand in the business units of fibre textile and fibre nonwovens, as well as in positive effects from current cost savings. V. Fraas 2D double-face warp knitted fabric (aramid/wool) Lenzing AG: Mandate extends The supervisory board has decided to extend the contract of Peter Untersperger (CEO) by another three years until March 2013. Christian Reisinger will retire from the company at his own request on 31 March 2010. After Christian Reisinger’s retirement the supervisory board intends to appoint a new third member of the management board, currently consisting also of Friedrich Weninger. inforced concrete”. Special sampling machines for 2D and 3D structures help to reduce development times to a minimum. All requirements are implemented as soon as possible. On the one hand, can made highly solid structures without structural elongation as the threads are inserted in a linear way. On the other hand, the structures are extremely flexible and elastic thanks to the loops. Further optimization can be achieved combining different materials. Especially developed machines are able to produce 3D bi-axle warp knitted structures. inforcements in thermosetting matrices and in concrete. A specially developed and at the fair presented 3D simulation technology enables to visualize double needle or single needle fabrics with or without weft insertion. This guarantees the optimal development and production process. www.solutions-in-textile.com textile network 1-2/2010 17