Fire Restitance Rating of Light weight wall construction

advertisement

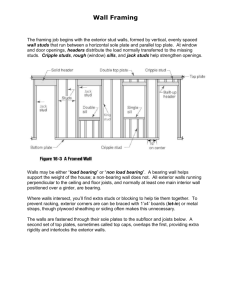

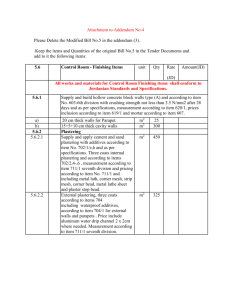

FPASA BULLETIN FD 12 FIRE RESISTANCE RATINGS OF LIGHTWEIGHT WALL CONSTRUCTIONS Increased use is being made of lightweight or dry-wall methods of construction for the internal walls in multi-storey buildings. There are both advantages and disadvantages inherent in the use of lightweight wall constructions when compared to the use of conventional plastered brick walls. The greater mass and nature of brickwork and most concrete blockwork ensures that, for internal walls, a far greater resistance to fire, impact loads and noise transmission is achieved. The quality of site workmanship seldom affects these properties in the case of plastered brickwork or blockwork. However, workmanship is of the utmost importance insofar as the fire resistance of lightweight walls is concerned and the fire-resistance time given in the table will be achieved only if the workmanship is of a high standard. The details at cross-wall junctions need to be designed and then executed on site in a manner that will ensure that the fire resistance at these positions is the same as that of the wall. The values in the table are intended merely to indicate to designers what fire resistance ratings can be expected from different types of lightweight wall constructions. General terms have been used to describe the types of wall constructions that utilise patented components such as, for instance, studs, board fixing devices, etc, which have achieved similar fire resistance ratings in wall furnace tests. Notes to table 1. 2. 3. 4. 5. 6. 7. 8. 4/2000 GP board means gypsum plasterboard. UA-C sheet means unpressed asbestos-cement sheeting, wet-cured or autoclaved. The same fire behaviour will not be achieved if pressed sheets are used. X-rated GP board means a special type of gypsum plasterboard which has a small percentage of glass fibre incorporated in the gypsum core of the board. When two layers of cladding material are used on one side of a wall, a joint between the cladding sheets of the second layer must not be on the same stud as a joint in the first layer. When fixing cladding materials to the studs or nogging pieces, it is important that the distances between fixing screws or nails should not be more than 300 mm both on gypsum plasterboard and asbestos-cement sheet materials. Also, when two layers of cladding are used on a side, the first layer must be fixed in the same manner as if only a single layer were to be used. The screw fixing of the second layer should be staggered vertically relative to the fixing of the first layer. By “steel studs” is meant cold-rolled galvanised steel. Class I impact is achieved by swinging a 30 kg sandbag twice against the face of the wall from a height of 0,45 m above the point of impact. When timber studs are used in walls, the walls are considered to be semi-combustible. Type and thickness of cladding as well as studs used in the construction of walls Stud spacing (mm) 1 x 12,7 mm thick GP board on either side of 65 x 35 mm steel studs 1 x 12,7 mm thick GP board on either side of 75 x 38 mm timber studs. Boards fixed vertically or horizontally 2 x 9,5 mm thick GP boards on either side of 65 x 35 mm steel studs or of 75 x 38 mm timber studs. 2 x 12,7 mm thick GP boards on either side of 65 x 35 mm steel studs or of 75 x 38 mm timber studs. 1 x 12,7 mm thick GP board on one side and 2 x 9,5 mm thick GP boards on other side of 65 x 35 mm steel studs or of 75 x 38 mm timber studs. 1 x 12,7 mm thick X-rated GP board on either side of 65 x 35 mm steel studs. Boards fixed vertically or horizontally. Composite cladding on walls 1 x 9,5 mm thick GP board and 1 x 9,5 mm UA-C sheet on either side of 65 x 35 mm steel studs. Unpressed asbestos-cement board cladding to walls 1 x 9,5 mm thick U-AC sheet on either side of 65 x 35 mm steel studs. As above but with mineral wool in the cavity. 1 x 9,5 mm thick UA-C sheet on either side of 75 x 38 mm timber studs with cavities filled with mineral wool. 2 x 9,5 mm thick U-AC sheets on either side of 65 x 35 mm steel studs. 1 x 12,7 mm thick U-AC sheet on either side of 65 x 35 mm steel studs or 75 x 38 mm timber studs. As done above but with a nominal 50 mm thick mineral wool insulation blanket in the cavity. 4/2000 Impact resistance Class Remarks on construction 450 Fire resistance rating (min.) 30 <1 600 450 20 30 <1 <1 Board fixed vertically or horizontally with or without glass wool or mineral wool in the cavity This type of construction is considered to be semi-combustible 600 20 <1 405 60 1 600 30 <1 450 60 1 600 30 1 450 30 1 (or < 1) 450 60 1 450 60 1 450 20 <1 600 20 Cladding sheets fixed to the steel studs with screws, so that the joints between the boards on each side of the wall are staggered. 450 30 <1 As above 600 450 30 30 <1 As above 405 60 1 450 30 <1 Boards can be fixed either vertically or horizontally or vertically and horizontally. The joints between the boards must be staggered. Cladding sheets fixed to studs with steel screws at 300 mm centres 600 450 20 30 >1 600 30 First layer of cladding can be vertical with second layer horizontal or viceversa. As above. If both layers are fixed vertically, steel studs placed back-toback and fixed to each other at 300 mm centres must be used. The double layer of boards must be used on the face most likely to be impacted during normal use eg the side bordering on a passage. The other side will have an impact of <1. If boards are fixed horizontally, then horizontal joints between boards must be backed by and fixed to nogging joints. Cladding materials can be either horizontal or vertical. Joints between boards must be staggered. As above. References: Anon, Fire Protection of buildings, FPASA Journal “Fire Protection” Vol. 4, No. 2 June 1977 E G Williams, Fire resistance ratings of some common lightweight wall constructions, FPASA journal “Fire Protection” Vol. 7 No. 1 March 1980. Published by Fire Protection Association of Southern Africa (Incorporated Association not for Gain) (Reg. No. 73/00022/08) P O Box 15467 Impala Park 1472 4/2000