Wall Framing - HRSBSTAFF Home Page

advertisement

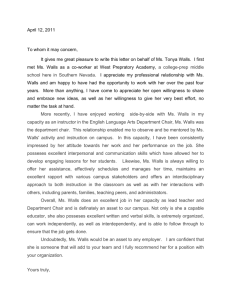

Wall Framing The framing job begins with the exterior stud walls, formed by vertical, evenly spaced wall studs that run between a horizontal sole plate and parallel top plate. At window and door openings, headers distribute the load normally transferred to the missing studs. Cripple studs, rough (window) sills, and jack studs help strengthen openings. Walls may be either “load bearing” or “non load bearing”. A bearing wall helps support the weight of the house; a non-bearing wall does not. All exterior walls running perpendicular to the ceiling and floor joists, and normally at least one main interior wall positioned over a girder, are bearing. Where walls intersect, you’ll find extra studs or blocking to help tie them together. To prevent racking, exterior corners are can be braced with 1’x4’ boards (let-in) or metal straps, though plywood sheathing or siding often makes this unnecessary. The walls are fastened through their sole plates to the subfloor and joists below. A second set of top plates, sometimes called top caps, overlaps the first, providing extra rigidity and interlocks the exterior walls. Sheathing Sheathing is a layer of plywood, Oriented Strand Board (OSB or Aspenite) or boards (ex. tongue and groove) that cover the exterior of a house's frame. The sheets range from 3/8” to 5/8” of an inch thick and come in 4’x8’ sheets. 3/8” is the minimum for walls, ½” is the minimum for roofs and 1/8” is required for OSB since it’s so strong. Walls may require a layer of sheathing to help strengthen the structure and to provide a nailing base for siding materials. (Plywood sheet siding may not require sheathing.) A layer of building wrap covers the sheathing or wall studs. The type of building wrap most commonly found is Tyvek. Tyvek is a brand of highdensity polyethylene fibers, a synthetic material; the name is a registered trademark of DuPont. The material is very strong; it is difficult to tear but can easily be cut with scissors or any other sharp object. Water vapor can pass through Tyvek (highly breathable), but not liquid water, so the material lends itself to a variety of applications: medical packaging, envelopes, car covers, air and water intrusion barriers (house wrap) under house siding. Carbon has recently been added to house wrap for UV protection. Before carbon was added the house wrap would photo-degrade over time, turning into dust. Rough openings for windows and doors The framing around the rough opening supports and transfers the structural weight above the window. The rough opening is made slightly larger than the window's actual size and rough opening dimensions are usually provided by the window manufacturer. Whenever a window is included in a building, it requires a header to bear the weight of the floors or roof above it. If the span is less than 4’ the header is constructed with 2 2’x4’s with a plywood spacer. NOTE: Manufacturers typically recommend the opening be 1/2" larger overall than the window. However, for better insulating between the window and framing, 3/4" overall is suggested. 6 Steps for Building Exterior Walls Framing exterior walls is a pretty straightforward process. Assembling walls on a level surface - probably the subfloor or slab - and raising them into place will help you frame faster. However, raising walls usually requires some extra help. Standard walls are 8' to 12' high. Older homes and warmer climates will have 2x4 wall studs. Newer homes in colder climates will use 2x6s, to create more space for insulation. Framing consists of top and bottom plates, wall studs and headers, with jack and king studs as needed for window and door openings. TIP: Before starting the layout process, chalk line the locations of the walls and their window/door openings on the subfloor. These marks will enable you to visualize and check the project's layout before the walls are made. The chalklines also serve as guidelines when actually raising the walls into place. 1. Marking Top & Bottom Plates Wall studs are generally spaced 16" on center (O.C.). Set the bottom (sole) plate and top plate flat. The first stud will sit on the end of the plate. Measure and mark 15-1/4" from the end for the near edge of the second stud. From this mark make marks every 16" for the near edges of the remaining studs. (The reduced spacing between the first and second studs ensures that a 4-footwide piece of sheathing can be flush with the outside edge of the first stud but land in the center of the fourth stud.) Where possible, on walls that run perpendicular to the floor joists, lay out the studs to line up over the floor joists for more structural strength. TIP: To keep track of the lines when marking the plates, use the 1-1/2" wide framing square leg to mark both edges of each wall stud. Most plans call for two top plate layers. Fit the second cap plate on the top plate, but cut it short to leave the ends exposed. After the walls are set you'll be able to overlap the corner joints. 2. Cutting Wall Studs Inspect the straightness of your wall studs before cutting them. Try to skip over ones with bad warps or twists, because they're hard to nail flush and can throw the stud spacing off. Keep them in mind for jacks or cripple studs. Wall studs can be cut out of standard lengths of 2x lumber. We like our walls to be 8' 1" high (from the top of the subfloor to the underside of the ceiling joists). With a 1/2" or 5/8" layer of drywall on the ceilings, two horizontal rows of 4' wide drywall on the walls, this will leave a gap of about 1/2" between the bottom of the lower row of drywall and the subfloor. Pre-cut studs are available 925/8" long to accommodate this wall height. If you're not using precut studs, cutting them to length can be done all at once. This saves a little time, but test fit and measure the first few studs to make sure they're the right length. 3. Assembling Walls & Corner Posts We usually assemble the wall on the floor, nail it together, then raise it into place. Working on a level surface is a major help in laying out the walls flush. Try to avoid assembling walls on the ground and keep the work surface clean by sweeping it periodically. Lay out the bottom and top plates on edge. Between the plates, insert the wall studs on their marks and nail the end studs in place. Once the wall is square, nail on the remaining wall studs. NOTE: It's a good idea to check for squareness by measuring diagonally from the corners after nailing on each end and after each wall is assembled. Where two walls meet in a corner there needs to be some extra framing to make sure that there's something on each wall for the drywall on both walls to nail into. One wall at every corner needs a corner "post." Here are two ways to create one: 1) Add 2x4 spacer blocks between the end stud and then install an extra "corner stud." 2) Lay an extra corner stud sideways, flush with the inside edge of the bottom plate. Once the corner post is secure, insulate the cavity before installing the sheathing. Once the sheathing is on and the wall goes up, the end of one wall section will cover the corner of the other making insulating impossible at that point. 4. Laying Out Window/Door Openings Most walls include a door or window opening. Additional framing support is needed to transfer the structural weight over the opening and down to the floor. This framing is done with jack, king and cripple studs and a header. On the top and bottom plates, mark the center of the window/door rough opening. An architect's plan will indicate where they go in relation to the corners, but double-check to make sure the openings are in the right places. Divide the opening widths in half and measure each direction from the center. These marks indicate where the inside edge of the jack studs go. Cut the jacks for the height of the rough window or door opening. Then nail them to full height king studs and install them together. They're easier to handle this way and you can plumb them in place in one step. Find the header length by measuring between the king studs. The header must be sized to meet local building codes. For single window or door openings three boards are nailed to each other often provide enough strength. Wider openings may require LVLs. Your lumber yard or home center may offer guidelines and material suggestions for different width openings. Nail the header in place, nailing through the king studs into the ends of the headers. Fit cripple studs on 16" centers above the header. In some cases the header may end up too close to the top plate to use cripple studs. So, that space must be filled with lumber of that thickness. For windows, a sill plate at the bottom of the opening is nailed into the jacks and supported by cripple studs under the sill plate on 16" centers. 5. Nailing On Sheathing Exterior sheathing, either 4x8 oriented strand board or plywood sheets, is nailed to the framed wall. It's always easier to nail on sheathing before raising the walls. The added weight on the wall is sometimes too much for two people to handle. So get extra help in raising the wall. It still beats working off a ladder and trying to nail up 4x8 sheets. Line up the sheets so the seams run down the middle of the studs. This way each piece will have a 3/4" surface to nail to. When you lay out the sheets, utilize the straight factory edges. Eliminate slight bows in the wall studs by pushing them to run evenly with the edge, then nail the sheathing in place. NOTE: Give a lot of attention to making straight cuts. You'll probably need to use some of these scrap pieces and they'll fit better with straight edges. 6. Raising & Bracing Walls Now the wall is ready to be raised. This may require some extra muscle, so get a few people to help out. With the wall still laying flat, position the bottom plate on a previously made chalkline mark (its width from the edge). Tack the bottom plate by toenailing a few nails through the top of the bottom plate to the subfloor. Slowly walk the wall upright. The tack nails will help hold the wall in place. Tap the wall flush and square it into place with a sledgehammer. Nail the bottom plate to the subfloor -- into the floor joists if possible. When the wall sections are nailed together, additional corner bracing is needed until the roof is framed to keep the walls from swaying. Overlapping the corner joints, nail the remaining cap plate sections on the top plates. You may be able to take some slight bows out of the top plates, but they'll need bracing. Run a stringline to check how straight the top plate is. Straighten any top plate bowing by pushing a brace board into the plate until it's flush. Anchor the brace by nailing it to a stake driven into the ground. Place 2x4s diagonally from the top corners to the rim joist, a long brace on one side and a short brace on the other. However, this is just a guideline. You may need even more bracing for your project. Wall Framing Questions This information will be on future tests/quizzes and the exam. 1. Label these parts of the wall: 2. What is conventional stud spacing? 3. What is the difference between a load bearing and a non-load bearing wall? 4. What is the purpose of building paper? 5. How much larger should the R.O. of a window be for better insulation? 6. Draw a three-stud arrangement for an exterior wall corner. 7. What is the function of the sole plate? 8. What is the common length of wall studs? Why are studs measured at this odd distance, and not a more round measurement? 9. What are cripples and jacks? 10. Why are headers needed? 11. In what kind of structure are extra studs used and why? 12. Describe the steps of plate layout. 13. What are the common materials used in exterior wall sheathing? 14. Describe the 6 steps when assembling a wall section. (1 point per each step, 1 point per each detail)