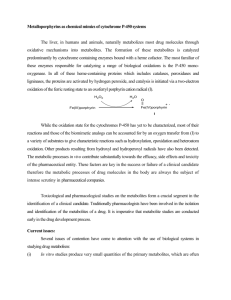

Scheme S1 Detailed mechanism of oxidation of ethylbenzne.

advertisement

Supplementary Information for Schiff base complex coated Fe3O4 nanoparticles: a highly recyclable nanocatalyst for selective oxidation of alkyl aromatics Lei Chen ● Bindong Li ● Dabin Liu Nanjing University of Science and Technology, 210094 Nanjing, China Results and Discussion Benzene, acetonitrile, ethanol, water, and dichloromethane were used as solvent to study the effects of solvent on the oxidation of ethylbenzene by TBHP over Fe3O4/SiO2/Cu(II)salpr catalyst (Fig. S1). Acetophenone was the major product in all reactions. The reaction had low conversion at the presence of coordinating solvents such as ethanol, while using water as a solvent made no reaction. As shown in Table S1, the maximum ethylbenzene conversion decreased on different solvents in the following order: 45% (benzene) > 32% (acetonitrile) > 28% (dichloromethane) > 20% (ethanol) > 0% (water). It seems that the donor electrons of these solvents had more ability to occupy the vacant space around the existed metal in catalyst, so this prevented coordinating from oxidant molecules [1, 2]. Further investigations showed that the reaction in solvent free condition had high selectivity and more catalytic activity. All the above E-mail: libindong@mail.njust.edu.cn showed that the ethylbenzene and solvents were competing for the active sites of metal center on catalyst. Scheme S1 shows a detailed mechanism of oxidation of ethylbenzene based on the precedent literature for similar catalyst in hydrocarbon oxidation by TBHP [2-5]. Captions: Fig. S1 The influence of solvent on the ethylbenzene oxidation by Fe3O4/SiO2/Cu(II)salpr catalyst. Conversion/ Selectivity a (%) Scheme S1 Detailed mechanism of oxidation of ethylbenzne. 100 83 Conversion 90 Selectivity 74 80 59 60 40 51 45 32 44 28 20 20 0 0 0 Solvent Fig. S1 The influence of solvent on the ethylbenzene oxidation by Fe3O4/SiO2/Cu(II)salpr catalyst. Conditions: catalyst (100 mg), ethylbezene (20 mmol), TBHP (30 mmol), 80 oC for 8 h. (a Selectivity toward the acetophenone.) O-C-(CH3)3 H O 2+ Cu 2+ (CH3)3-C-O-O-H + Cu OH + (CH3)3-C-O Cu (CH3)3-C-O + CH2 CH3 (CH3)3-C-OH 2+ Cu OH 2+ + CH CH3 OH C H OH C H + Cu O Cu CH3 CH3 + (CH3)3-C-O O C H CH3 + Cu OH + C O C H + H2O CH3 O + 2+ Cu + CH3 2+ Cu O H + (CH3)3-C-OH 2+ 2+ CH3 2+ OH C H Cu OH CH CH3 2+ + Cu OH + H O + OH + CH3OH + H2O Scheme S1 Detailed mechanism of oxidation of ethylbenzne. References [1] Uber JS, Vogels Y, Van Den Helder D, Mutikainen I, Turpeinen U, Fu WT, Roubeau O, Gamez P, Reedijk J (2007) Eur J Inorg Chem 26: 4197 [2] Habibi D, Faraji AR (2013) Appl Surf Sci 276:487 [3] Masteri-Farahani M (2008) J Mol Catal A: Chem 284:97 [4] Parida KM, Dash SS (2009) J Mol Catal A: Chem 306:54 [5] Arshadi M, Ghiaci M (2011) Appl Catal A: Gen 399:75