hyster® big trucks further lower fuel usage

advertisement

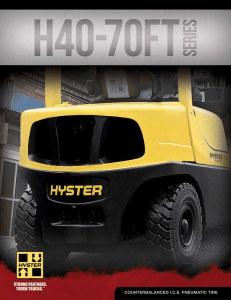

PRESS RELEASE May 2014 HYSTER® BIG TRUCKS FURTHER LOWER FUEL USAGE THROUGH INTRODUCTION OF STAGE IV / TIER 4 FINAL Hyster has launched a full range of Stage IV / Tier 4 final compliant Big Trucks offering fuel savings of up to 25% for ports, terminals and heavy industry. In July 2014, the first Hyster Big Trucks above 18t lifting capacity will leave the production line in Nijmegen, the Netherlands, featuring EGR, DOC and SCR technologies to meet the Stage IV / Tier 4 final (T4f) legislation. In close cooperation with its partners, Hyster has managed to further reduce operational costs for customers through intelligent design, rigorous field testing and a significant number of engineering hours. “Our goal was to continue our Profitable Low Emissions strategy reducing the total cost of operations and ownership while meeting the new standards for a cleaner environment,” says Jan Willem van den Brand, Product Strategy Manager Big Trucks. “Building upon the success we have had with Stage IIIB / Tier 4i where we achieve up to 20% fuel savings, we managed to get another 5% going to Final. So we now have up to 25% fuel savings on our 2014 models compared to Stage IIIA 2010 trucks and many of our competitors.” The additional fuel savings greatly offset the very low Urea consumption averaging about 3.5% of fuel consumption (Urea is generally half the cost of Diesel). As the trucks do not need a DPF the running cost associated with that is also eliminated. The Hyster 5-8 high empty container handler, the 18-20t and 25-32t forklift truck ranges feature the latest Cummins QSB 6.7 engine (up to 270 hp, 201kW) and a 5 PRESS RELEASE speed ZF transmission. On the larger models, the Cummins QSL9 (up to 370 hp, 276kW) provides power for the 36-48t forklift trucks, laden container handlers and Hyster Reach Stackers. “We had the first Stage IV / T4f test trucks running back in May 2012 and have since collected thousands of validation hours in real life applications” he says. “We have built on the operational success of our Stage IIIB / Tier 4 Interim products launched back in 2010 where we ‘right sized’ the engines”. Hyster decided to use heavy EGR (exhaust gas recirculation) combined with SCR (selective catalytic reduction) and a DOC diesel oxidation catalyst to achieve Stage IV / T4f compliance, resulting in approximately 96% less particles (soot) and 94% less NOx (nitrogen oxides) compared to Stage IIIA / T3 equivalents before 2005. EGR reduces NOx formation during combustion, preventing the majority of the NOx formation, followed by SCR which removes the remaining NOx from the exhaust stream. This provides the best possible control of NOx at all engine loads and exhaust temperatures allowing fully optimised power and response and low fuel consumption. This combination requires low DEF (Diesel Exhaust Fluid) usage with no risk of crystallisation. For PM (particulate matter) reduction, high pressure fuel injection reduces PM formation at source and a diesel oxidation catalyst (DOC) removes remaining PM from the exhaust stream. There is no DPF (diesel particulate filter), no additional operator intervention or ash cleaning service required. In addition, the DOC increases the exhaust temperature allowing normal idle rpm. “EGR and DOC allow a controlled burn,” Jan Willem says. “With a smaller block size, a larger power range can be achieved.” In addition to the Cummins engine technologies, Hyster performance optimisation developments such as cooling on demand, ECO-eLo mode, RPM management and alternate engine idle speed, help to further reduce the total fuel consumption. On the empty container handler, the 18-20t and 25-32t forklift truck ranges Hyster is also introducing the ZF transmission with a stiffer torque converter, improved shift PRESS RELEASE point selection and five forward gears. This allows the truck to drive at full speed at only 1450 RMP instead of 2100-2300 RPM with conventional transmissions. This results in a low fuel usage and noise level whithout loss of preformance. In addition to the proven results on the 25-32t Hyster forklift truck range and Reach Stackers the empty container handler and the 18-20t forklift truck range now also have load sensing hydraulics. The hydraulic on demand allows a high lifting speed at low RPM. “Our fuel saving compared to a 2010 Tier 3 truck model is now generally up to 25%, often more, without loss of performance" he says. With engine, transmission and hydraulic protection systems, Hyster ensures excellent reliability in the most demanding operations and has proven performance results. T4f is the EPA regulation for North America and Stage IV is the EU equivalent and, from 2014, they affect all diesel powered off-highway equipment available for sale in these markets with power ratings over 173 hp (130 kW). A selection of previous Hyster models is still available for sale to regions outside of the EU and North America, including the ZF transmission and load-sensing hydraulics improvements. “Hyster has once again used the introduction of new legislation to improve its leading role in fuel economy. Following the introduction of our previous products we recognised that our customers value the low fuel usage of the Hyster equipment, especially when they noticed a significant reduction in their fuel bill,” says Jan Willem, explaining that this led Hyster to invest further Research and Development into fuel reducing technology. All Hyster products are supported worldwide by a network of highly trained dealers providing expert, responsive local service and customisations for specific industries. Visit www.hyster.eu. ENDS – 883 Words PRESS RELEASE NOTES TO EDITORS Hyster is one of the leading global brands of materials handling equipment offering over 140 models of counterbalance trucks, warehouse and container handling equipment. The company invests heavily in research and development to ensure Hyster® products are at the forefront of the materials handling industry providing maximum dependability and low costs of ownership for demanding operations everywhere. Hyster Company is part of NACCO Materials Handling Group, Inc. (NMHG), a wholly owned subsidiary of Hyster-Yale Materials Handling, Inc. (NYSE:HY). Hyster-Yale Materials Handling, Inc. and its subsidiaries, headquartered in Cleveland, Ohio, employ approximately 5,100 people worldwide, with 1360 in the EMEA region. Visit www.hyster.eu for further information. Issued on behalf of Hyster Europe by: MOLOKINI MARKETING LTD Press/Advertising contact : Nik Webb, Tel: +44 (0) 1903 207408 nik@molokini.co.uk | www.molokini.co.uk