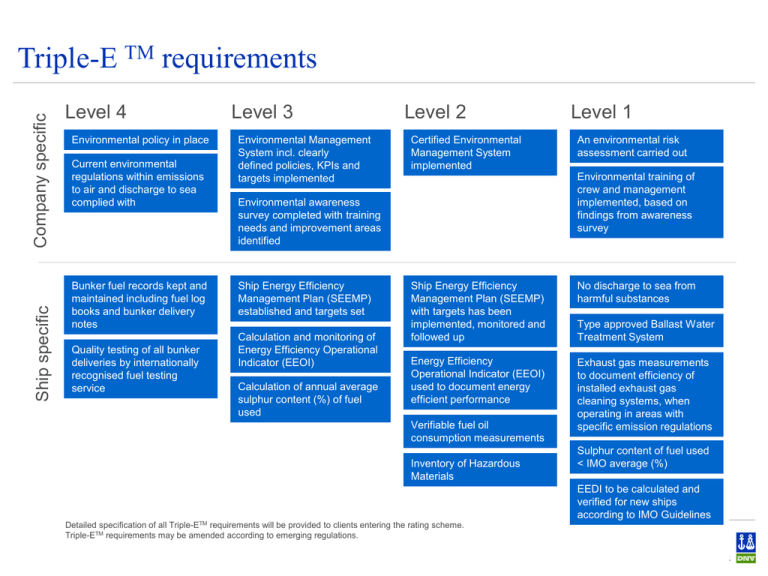

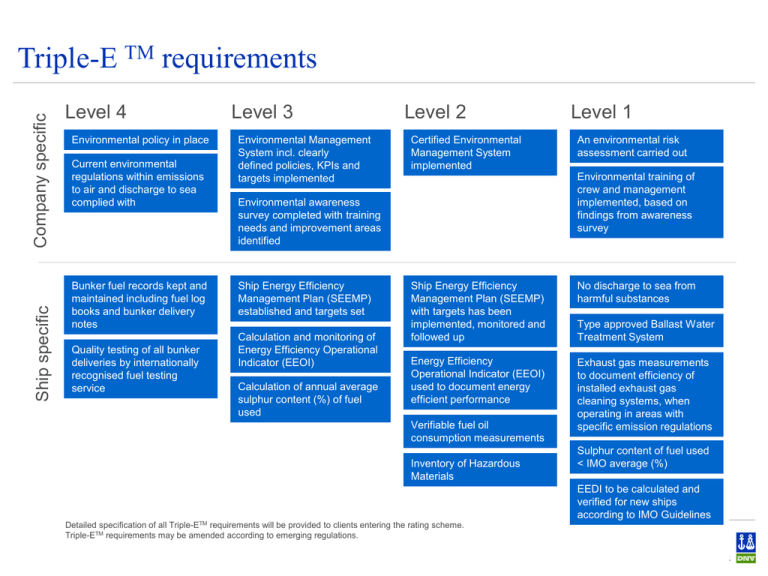

Ship specific

Company specific

Triple-E TM requirements

Level 4

Environmental policy in place

Current environmental

regulations within emissions

to air and discharge to sea

complied with

Bunker fuel records kept and

maintained including fuel log

books and bunker delivery

notes

Quality testing of all bunker

deliveries by internationally

recognised fuel testing

service

Level 3

Level 2

Environmental Management

System incl. clearly

defined policies, KPIs and

targets implemented

Certified Environmental

Management System

implemented

Level 1

An environmental risk

assessment carried out

Environmental training of

crew and management

implemented, based on

findings from awareness

survey

Environmental awareness

survey completed with training

needs and improvement areas

identified

Ship Energy Efficiency

Management Plan (SEEMP)

established and targets set

Calculation and monitoring of

Energy Efficiency Operational

Indicator (EEOI)

Calculation of annual average

sulphur content (%) of fuel

used

Ship Energy Efficiency

Management Plan (SEEMP)

with targets has been

implemented, monitored and

followed up

No discharge to sea from

harmful substances

Energy Efficiency

Operational Indicator (EEOI)

used to document energy

efficient performance

Exhaust gas measurements

to document efficiency of

installed exhaust gas

cleaning systems, when

operating in areas with

specific emission regulations

Verifiable fuel oil

consumption measurements

Inventory of Hazardous

Materials

Type approved Ballast Water

Treatment System

Sulphur content of fuel used

< IMO average (%)

EEDI to be calculated and

verified for new ships

according to IMO Guidelines

Detailed specification of all Triple-ETM requirements will be provided to clients entering the rating scheme.

Triple-ETM requirements may be amended according to emerging regulations.

Thursday, 07 April 2011

© Det Norske Veritas AS. All rights reserved.

1