the full hyster line for port centric operations

advertisement

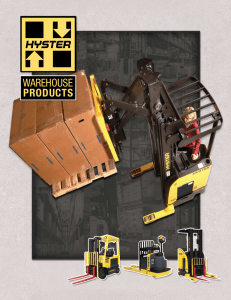

PRESS RELEASE May 2014 THE FULL HYSTER LINE FOR PORT CENTRIC OPERATIONS The full range of Hyster materials handling equipment, from pallet trucks to container handlers, plays a key role in many port centric operations. Hyster remains the only full line supplier providing a complete solution to transfer goods from ship to store. Enabling the unloading of containers close to a port so that palletised freight moves inland and empty containers can be returned straight to the exporting berth is not new, but it is an increasingly popular supply chain model. “The handling needs at ports, terminals and port centric warehouses in the hinterland perfectly illustrates how materials handling equipment of all sizes and types is used at various stages of the supply chain, from ship to shore to the store and onto the shop floor” explains Kate Pointeau, Brand Manager, Hyster. The complete Hyster range includes Reach Stackers, container handlers, high lift capacity (up to 48 tonnes) forklift trucks, Fortens® IC forklift trucks from 2-9 tonne lift capacity, electric forklift trucks and a variety of warehouse equipment. "Hyster brings reliability, strength, low cost of operation and energy efficiency to every application," says Kate. "These principles of design run across our unique full line offering allowing one supplier across a port and hinterland." From Ship to Shore to Store Expert in container handling, Hyster is a world leading supplier of container and intermodal handlers. Hyster ReachStackers and Container Handlers, used to transfer and stack shipping containers in ports and terminals, are reported to offer significant PRESS RELEASE savings in fuel costs thanks, partly, to the optimised Tier 4i / Stage IIIB engines. These fuel saving benefits will be further enhanced for Hyster customers by the latest Tier 4f/Stage IV compliant engines, which are being progressively introduced to the market and showcased at the Hyster HUB event in May 2014. Once transferred from the container yard to the port centric warehouse, pallet trucks and forklifts of various sizes are used to unload the containers and transfer palletised goods to the marshalling areas. "It is essential for handling operations to match the truck to the application intensity, particularly for container de-stuffing" says Kate. "The Fortens® series of IC forklift trucks, for example, offers many possible configurations to match the needs of the most demanding 24hr applications." As an alternative for general use, the Hyster CT series offers excellent value for non-intensive use in standard applications. The Inside Story To move goods in the warehouse store, Hyster has a full range of equipment including order pickers, pallet trucks, VNA (very narrow aisle) equipment and the recently launched Hyster® Reach Truck. "Hyster equipment helps businesses to achieve greater efficiency and optimise port centric picking and packing operations," she says. “Our aim is to keep businesses moving and we have made a significant investment in developing some of the toughest and most reliable warehouse trucks on the market.” While reliability is fundamental with regards to costs, throughput and driver productivity, other factors contribute to the ultimate goal of reducing the customer’s total cost of ownership, such as energy efficiency and truck performance. The powerful Hyster® JXN electric forklift range is one of the most energy efficient on the market, helping businesses to reduce carbon footprint and energy bills and get better shift life. With pneumatic and cushion tyre variants, the tough 1.5–5 tonne capacity models excel in indoor or outdoor arduous operations. Such robust design and outstanding traction was previously only expected from IC trucks. PRESS RELEASE To enhance productivity when transporting, stacking or loading pallets for their inland journey, Hyster pallet and stacker trucks provide high reliability, power and precision with a low cost of operation. Pick speed and reliability are essential in picking operations, and the Hyster low level order picker with scooter like control is designed to get the best performance from individual pickers, ensuring loads are placed at the optimum height for the operation with maximum machine reliability. At height, pickers gain maximum pick face access using the Hyster K series of rising cab order pickers, with fast simultaneous lift and horizontal movement (using rails or wire guidance). To maximise space with very narrow aisles and tall racking, the Hyster VNA truck has been developed to help operators efficiently retrieve pallets in high intensity operations up to 17m. To deliver one of the quickest VNA transits in the industry, the horizontal movement intelligently combines with vertical movements, and the patented QUAD form mast design provides unmatched rigidity and torsional strength, with proven reliability. Offering travel speeds of up to 14 km per hour and a lift speed of 0.8 metres per second, the new Hyster Reach Truck has been designed to lift loads up to 12.5 metres. “The latest Hyster Reach Truck model offers superb reliability, dependability and a low cost of ownership in intense warehouse operations” says Kate Pointeau. Residual capacity is maintained to greater heights thanks to the new unique patented channel mast design and visibility is enhanced through reduced total channel width. Tailored Solutions “To support the decision making process and help specify the right mix of trucks, we can use 3D warehouse simulation software to demonstrate how Hyster products will work in the application before they are specified or implemented,” she explains. Once in operation, the fleet can be managed effectively with the new Hyster Tracker, a Wireless Access Monitoring System that helps keep tough Hyster forklift trucks running for even longer and even more productively. PRESS RELEASE Hyster products and services can also be tailored, as required, to the most specific and demanding environments such as explosion proofing and where attachments are required. All Hyster products are supported worldwide by a network of highly trained dealers providing expert, responsive local service and a single point of contact for the full range of Hyster equipment used across the port area and hinterland. For more information please visit www.hyster.eu. ENDS – 964 Words NOTES TO EDITORS Hyster is one of the leading global brands of materials handling equipment offering over 140 models of counterbalance trucks, warehouse and container handling equipment. The company invests heavily in research and development to ensure Hyster® products are at the forefront of the materials handling industry providing maximum dependability and low costs of ownership for demanding operations everywhere. Hyster Company is part of NACCO Materials Handling Group, Inc. ( NMHG), a wholly owned subsidiary of Hyster-Yale Materials Handling, Inc. (NYSE:HY). Hyster-Yale Materials Handling, Inc. and its subsidiaries, headquartered in Cleveland, Ohio, employ approximately 5,100 people worldwide. Visit www.hyster.eu for further information. Issued on behalf of Hyster Europe by: MOLOKINI MARKETING LTD Press/Advertising contact : Nik Webb, Tel: +44 (0) 1903 207408 nik@molokini.co.uk | www.molokini.co.uk