Corrosion of calcium nitride by hydrogen to form ammonia

advertisement

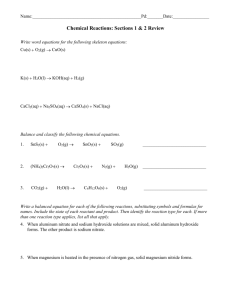

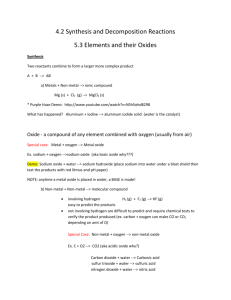

Analysis of the reduction of magnesium oxide and the corrosion of calcium nitride by hydrogen as potential parts of a proposed process for solar thermochemical synthesis of ammonia Brian Peterson NSF REU Program, Kansas State University Center for Sustainable Energy Department of Chemical Engineering, Missouri University of Science and Technology Executive Summary Reducing magnesium oxide to either magnesium metal or magnesium nitride is a possible step in a solar thermochemical ammonia production process. It appears from preliminary data that the addition of chromium(III) oxide is more effective than iron(III) oxide at increasing the reduction of magnesium oxide. Also, more magnesium oxide is reduced with a greater presence of the reducing agent carbon. For some yet undetermined reason, x-ray diffraction analysis of solids composition has proved ineffective for this experiment. The composition of the solids remaining from reacting calcium nitride with hydrogen was to be determined. The remaining solids after several reactions show a variety of compounds with varying ratios of calcium, nitrogen, and hydrogen. This could be an indication of a complex pathway to liberated nitrogen as ammonia with several intermediate steps. The composition of the remaining solids varies dramatically with temperature. At higher temperatures volatility of certain material can also change the solids’ composition, such as the calcium hydride. Calcium hydride apparently was able to vaporize and leave the system somewhere between 700 and 1000 °C. Preliminary results also indicate that ammonia production may level off after about 700 °C. That is why that temperature was chosen for the kinetics analysis. Also, it was found that varying the hydrogen flow rate has no clear influence on the reaction rate. This indicates a diffusion limited reaction. Introduction Nitrogen fertilizers are critical to agricultural. Crops feed us directly and feed the livestock which we then consume. Additionally, agricultural products are in increasing demand for various forms of bio-energy. The fields in which these crops are grown must be fed a steady diet of digestible nitrogen in the form of ammonia or various ammonium salts in order to avoid depleting the soil nutrition. Presently ammonia is produced by the Haber-Bosch Process, which has been the standard for nearly 100 years. Without this process, roughly one third of the world's population could not be sustained. Through chemistry, food is made from the nitrogen in the air as it is "fixed" in the form of ammonia. Despite the necessary benefits, there is room for improvement. Haber-Bosch is not a very green process. World-wide the Haber-Bosch Process accounts for almost 2% of the world's energy consumption. It requires one ton of natural gas for every ton of ammonia produced and operates at extremely high temperatures and pressures. Kansas State Chemical Engineering PhD student Ronny Michalsky, under the direction of his mentor professor Dr. Peter Pfromm, has been exploring possible alternatives. The potential process would utilize a metal nitride which would react with a hydrogen source (water or hydrogen gas) to form ammonia and a remaining solid. The solid, usually a metal oxide, must be somehow then reduced to its original metal so it can then be nitridated back to the metal nitride, and the cycle can begin again. Reducing this metal oxide can prove difficult. It requires high temperatures and the presence of a reducing agent such as carbon. So theoretically this process would only require inputs of water, nitrogen (from air), and carbon for outputs of the desired ammonia and carbon monoxide which could be utilized in other chemical syntheses. The process would operate at ambient pressure, and high temperatures required by certain legs of the cycle are produced by magnified sunlight (solar energy). The search for the ideal reactants and the ideal reacting conditions is critical to developing this alternative process. First, a reaction involving the optimization of the reduction of magnesium oxide was studied. This was done by reacting the magnesium oxide with nitrogen in the presence of carbon as a reducing agent. Figure 1: Basic overall reaction cycle of magnesium oxide. The reaction with the smaller dashed line around it is the one being studied Additionally an alternative metal oxide will be added in hopes of reducing the reaction temperature. Either iron(III) oxide or chromium(III) oxide was added during experiments. The ultimate goal of this reaction is to form magnesium nitride and to maximize its yield by varying the stoichiometric ratios of the carbon and alternative metal oxide. Data on the kinetics of the reaction were gathered, but the results after analysis proved wildly inaccurate. It is important to note that this reaction was heated using solar energy from a solar concentrator described later. The other reaction studied involves reacting calcium nitride and hydrogen. Originally the metal nitrides were readily reacted with water, forming ammonia and a metal oxide. The metal in the metal oxides have proved very difficult to reduce and recycle back to the easily reacted metal nitride. The fact that hydrogen contains no oxygen molecule like water does should circumvent the production of a metal oxide. Figure 2: The overall reaction cycle using calcium nitride and hydrogen. The reaction with the smaller dashed line around it is the one being studied. How much nitrogen will be released (in the form of ammonia rather than gaseous nitrogen) from the solid state calcium nitride into the gas phase is unknown. What is also uncertain is the nature of the “solids” left behind. Additionally, the kinetics of the reaction at 700 °C were studied. Materials and Methods Reduction of magnesium oxide Samples of solid reactant were prepared by mixing magnesium oxide (99.95% pure, -325 mesh, NOAH Technologies Corporation) with various stoichiometric ratios of carbon (graphite powder, crystalline, -300 mesh, 99%, Alfa Aesar) and either iron(III) oxide (anhydrous, 99.95% pure, -325 mesh, typ. 0.3 micron, NOAH Technologies Corporation) or chromium(III) oxide (anhydrous, 99% pure, -325 mesh, NOAH Technologies Corporation). The powder was then thoroughly crushed and mixed to ensure uniformity. The various mixtures (eight total) were stored in a refrigerator until needed. Once needed, enough of each mixture was weighed so that there were 50 mg of Magnesium Oxide present in the reaction. The mixture was then placed into a tubular flow through reactor (27 mm inner diameter, ID, 30 mm outer diameter, OD, 200 mm length, fused quartz, Technical Glass Products). The nitrogen for the reaction was provided at a Table 1: molar composition of mixtures Mixture 1 Molar Ratio 1:1:4 MgO:Fe2O3:C 2 1:1:8 MgO:Fe2O3:C rate of 2 liters/minute, measure by a gas flow meter (Omega Engineering). The appropriate temperature was attained by mounting a Fresnel lens (0.93 x 1.24 m, 0.7 mm thickness, 1.03 m focal 4 1:1:8 MgO:Cr2O3:C length, UV filtering acrylic, geometrical concentration ratio ~ 5 2:1:5 MgO:Fe2O3:C 2440 [49], Mitsubishi TV) onto a custom aluminum scaffold 6 2:1:10 MgO:Fe2O3:C (Skarda Equipment Company). The scaffold had to be 7 2:1:5 MgO:Cr2O3:C manually adjusted approximately every three minutes to 8 2:1:10 MgO:Cr2O3:C maintain alignment with the sun. This device is referred to as the Solar Concentrator. Temperature was checked before the experiment using a thermocouple (High Temperature Flexible Ceramic Fiber-Insulated Probe, Type K; IR-Pro Infrared Thermometer, 1371 °C maximum temperature (Tmax), both ThermoWorks). To determine the temperatures above the thermocouple’s limits and the maximum temperature, silicon, iron, and chromium powders were melted (Tmax≈1600 °C at a solar power flux of Psolar≈0.85 ± 0.03 kW/m2). This process also allowed the Solar Concentrator to be calibrated for temperature at various distances from the focal point for ease of temperature adjustment. Additionally, the solar power flux before entering the lens was monitored using a solar meter (SP1065, 300-1100 nm wavelength detection range, EDTM Glass, Window & Film Test Equipment). The first set of 8 experiments was performed at 1200±100 °C. The temperature varies so much because of the constantly moving focal point. 3 1:1:4 MgO:Cr2O3:C The end of the tubular reactor was plugged with quartz wool to capture any vaporized magnesium that may have been formed by reduction. The solid samples were exposed to the flowing nitrogen and the specified temperature for 30 minutes. The samples of quartz wool and the reacted solid were collected for analysis. Each of those two samples were then divided and part was dissolved in 10 mL of 0.0107 molar hydrochloric acid, the other part was inerted with argon and stored. Thus each experiment yielded four samples to analyze: two liquid and two solid. For kinetics data, reactions were run using the indoor reactor and furnace (explained in the corrosion of calcium nitride section) to insure a stable temperature at 1200 °C. Mixtures 2, 4, and a reference analogous to them without iron or chromium oxides were reacted 3 different times each at time intervals of 30, 60, and 120 minutes. Thus, 9 total reactions were run for kinetics data. Only the remaining solid samples were collected. Corrosion of calcium nitride by hydrogen to form ammonia The reactant, calcium nitride, was prepared by using the indoor reactor setup, rather than the solar concentrator. Approximately 4 grams calcium metal (99%, granular, Acros Organics) was placed in a quartz boat which was then placed in a tubular reactor (60 mm ID, 1 m length, quartz, model HTF55347C, Lindberg/Blue). Nitrogen was allowed to flow over the solids for 4 hours at 2 L/min. The reaction was heated to a temperature of 750 °C by an electric furnace and a temperature controller (model CC58434C, Lindberg/Blue). The product was then crushed to a fine, uniform powder in the presence of argon gas to prevent unwanted corrosion. The sample was then inerted with argon and stored under refrigeration until needed for experiments. It is important to note that both water and oxygen will cause unwanted corrosion of the calcium nitride. To prevent this, reactants or products of these reactions must always be inerted by argon or nitrogen gas with the exception of weighing samples, moving from one inert vessel to the next, or during solid state analysis (after which the sample is discarded anyway). When transporting exposed calcium nitride over any significant distances, a trash bag full of argon was used as a temporary vessel. The first set of experiments with calcium nitride revolved around varying temperature. The same indoor reactor setup as described in the previous paragraph was used with one modification. A flask filled 25 mL of 0.0107 molar hydrochloric acid was placed in an ice bath, and the effluent gas from the reaction was allowed to bubble through the liquid. This setup allows the ammonia formed by the reaction to be captured in the very stable form of the ammonium ion. While the reaction was being prepared, the tubular reactor was allowed to purge (~5 min.) by nitrogen at 2 L/min. at 200 °C. Roughly 0.5 g calcium nitride was placed in a quartz boat and then into the reactor. The reactor temperature was elevated to desired levels while the inert nitrogen was still flowing. Once the reaction temperature was reached, reactive hydrogen was turned on at a flow rate of 0.5 L/min. For 1 hour hydrogen gas was allowed to flow over the solid reactant. Experiments at 4 different temperatures (300, 500, 700, 1000 °C) were performed. After analyzing the results of the previous 4 reactions, it was determined that the reaction at 700 °C was the best case for analyzing reaction kinetics. This is because the 700 and 1000 °C reactions both produced similar amounts of ammonia (see Results and Discussion), but the lower temperature is favored because of the lower energy requirements. The experimental setup to analyze the reaction kinetics at 700 °C was very similar the previous 4 experiments. The reaction was run for two hours while 4 mL samples from a flask initially filled with 50 mL of 0.0107 molar hydrochloric acid were taken at 1, 5, 10, 30, 60, and 120 minutes into the reaction. This procedure was repeated for 4 different flow rates of hydrogen gas (0.2, 0.5, 1.0, and 2.0 L/min.). Chemical analysis The solid products of the reactions were analyzed using x-ray diffraction (XRD). The particular machine utilized was the Miniflex II diffractometer (Cu-target X-ray tube, 30 kV / 15 mA output, diffracted beam monochromator, Rigaku). The machine was set to scan through specific angles of detection (5-80 °2θ range, 1 °2θ/min scan speed, 0.02 data points/°2θ, continuous mode). The results of this process were analyzed using PDXL Software (Version 1.6.0.0). The solid state analysis allowed the approximate weight percent composition of solid products to be determined. The concentration of the ammonium ion within liquid samples was identified using an ammonium Ion Selective Electrode (Denver Instruments) which was attached to a pH/ISE Controller (model 270, Denver Instruments). This device measures the flux of ammonium ions across a membrane by reporting a voltage. On one side of the membrane is 2 mL of 0.1 molar ammonium chloride at a pH of ~13 which was attained using 0.2 mL of 10 molar sodium hydroxide. The ISE had to be calibrated by measuring the voltage outputs of known samples of ammonium ions. Values were taken at 0.01, 0.1, 1, 10, 100, and 1000 ppm ammonium ion. A logarithmic regression of the results was then used to determine ammonium ion concentration as a function of voltage. Results and Discussion Reduction of magnesium oxide The goal of this reaction was to reduce the magnesium oxide. Ideally magnesium nitride will be the compound found. Magnesium nitride is desired because it can be directly reacted with water to ultimately produce ammonia. It is also possible that magnesium metal itself was formed. In this case, the magnesium metal would likely vaporize at the reactor temperature and subsequently recondense onto the quartz wool which was packed into the end of the tubular reactor. In the analysis of the quartz wool, finding magnesium oxide is most likely because of the reactivity of magnesium in the presence of oxygen. After XRD analysis of the quartz wool, it became apparent that if there was any magnesium or magnesium oxide present, the silicon dioxide of the quartz wool proved to abundant and masked any other compounds present. The results of the XRD analysis for mass composition of the remaining solids of the 8 mixtures at 1200±100 °C are shown in Table 2. Table 2: XRD composition results for the mixtures from Table 1 Compound Name Formula Carbon C Chromium Cr Chromium Carbide Cr7 C3 Chromium Nitride Cr2 N Eskolaite, syn Cr2 O3 Iron Nitride Fe8 N Iron Oxide Fe0.925 O Iron(III) Oxide Fe2 O3 Magnesium Nitride Mg3 N2 Periclase, syn Mg O Tongbaite Cr3 C2 Wustite, high Fe0.909 O Wustite, syn Fe0.911 O Mixture 1 17.18% 2 55.00% 3 19.40% 7.00% 20.26% 25.81% 10.86% 17.00% 13.14% 0.97% 35.36% 1.37% 13.00% 13.80% 2.12% 25.42% 4 23.97% 5 33.56% 6 44.88% 7.89% 21.06% 23.84% 10.57% 12.67% 10.31% 0.44% 41.94% 3.37% 15.95% 0.15% 35.65% 7 22.02% 8 41.69% 3.36% 40.07% 33.30% 0.43% 31.02% 3.10% 22.48% 13.75% The results from Table 2 demonstrate the relative amounts of magnesium nitride formed, but it is also apparent from the large variety of compounds detected that there are fairly large inaccuracies in the XRD analysis. For instance, the detection of iron nitrides are most likely due to the presence of nitrogen gas entrained in iron. This uncertainty makes it difficult to judge the accuracy of the results. Due to a malfunctioning ISE, results from all the soluted samples could not be found. For analysis of the kinetics experiments, a simple mass balance was done on magnesium atoms. If they were retained in the sample as magnesium oxide, the magnesium was not reduced. If magnesium metal were produced it would very likely vaporize and exit the system. Thus the weight percent of magnesium lost should indicate reduction of that metal as a function of reaction time. Table 3: Weight percent of magnesium lost in the reaction at various reaction times % Mg Lost Molar Ratio MgO:C:FeO3:Cr2O3 30 min. 60 min. 1:8:0:0 49.21% 50.55% 1:8:1:0 -60.80% -74.01% 1:8:0:1 7.09% -24.82% 120 min. -43.35% -154.78% 44.06% It is apparent that there are wild errors involved. All highlighted sections of Table 3 indicate a negative magnesium loss, and thus magnesium was created. This cannot be true. This data is useless until more effective analytical techniques can be found. 0.17% 24.83% Corrosion of calcium nitride by hydrogen to form ammonia The two aspects of the analysis for this reaction at 4 different temperatures were to determine the amount of ammonia formed and the composition of the solids left after the duration of the reaction. The results of the XRD analysis for mass composition of the remaining solids are in Table 4. Table 4: Composition of the solids following reactions at various temperatures Compound Reaction Temperature (°C) Name Molar Mass (g/mol) Formula 300 500 Calcium Nitride 148.24 Ca3N2 56.51% 57.01% Calcium Oxide 36.08 CaO 4.86% 8.88% Calcium Hydroxide 74.08 Ca(OH)2 18.61% 11.70% Calcium Nitride 94.16 Ca2N 20.02% 0.00% Calcium Hydride 42.08 CaH2 0.00% 14.73% Calcium Hydride Nitride 95.16 Ca2HN 0.00% 7.68% 700 0.00% 15.75% 19.17% 0.00% 11.57% 53.54% 700 0.00% 16.59% 20.20% 0.00% 21.51% 41.71% It is interesting to note that calcium hydride appears at higher temperatures and then disappears suddenly in the 1000 °C reaction. This is due to vaporization of that product. Due to ISE failure, all liquid samples remain unanalyzed. Further analysis can determine the percent of nitrogen liberated to the gas phase. This is a very close indicator of the amount of ammonia formed. Figure 3: Mole percent of nitrogen atoms released to the gas phase as a function of temperature. This should closely mimic the production of ammonia. 70% Percent N Liberated to Gas Phase 60% 50% 40% 30% 20% 0 200 400 600 Temperature (°C) 800 1000 1200 1000 0.00% 16.88% 20.39% 0.00% 0.00% 62.73% The next step in analyzing this reaction was to study the effects of different hydrogen flow rates. A plot of the mole percent of nitrogen liberation which correlates to ammonia production as a function of hydrogen flow rate can be seen in Figure 4. Figure 4: Mole percent of nitrogen atoms released to the gas phase as a function of hydrogen flow rate. This should closely mimic the production of ammonia. 100.00% Percent N Liberated to the Gas Phase 80.00% 60.00% 40.00% 20.00% 0 0.5 1 1.5 2 2.5 Hydrogen Flow Rate (L/min.) No clear trend appears with flow rate change. Liquid samples taken at various time intervals during the reaction could not be analyzed due to ISE failure. Additionally, minimum energy requirements to separate the ammonia from the unreacted hydrogen were performed. Figure 5: Minimum energy requirements for separation of ammonia from hydrogen at various hydrogen flow rates. Calculated using wmin=-RT[xNH3ln(xnh3)+xH2ln(xH2)] 19 18 17 16 15 14 13 Miniumum Energy of Separation (kBTU/ton ammonia) 12 11 10 0 0.5 1 1.5 Hydrogen Flow Rate (L/min.) 2 2.5 When increasing hydrogen flow, there appears to be no effect on ammonia production, but it does effect the energy of separation. Conclusions and Outlook Reduction of magnesium oxide The first part of analyzing this reaction is studying the effects of adding iron(III) oxide and chromium(III) oxide and various amounts of carbon to the reaction. Table 2 indicates that chromium oxide has the greater influence on the reduction of magnesium oxide. Data also suggests that adding more of the reducing agent carbon increases the reduction. Further analysis of the effectiveness of these additional reactants should be pursued, perhaps without using the Solar Concentrator which has high temperature fluctuations. Instead, an indoor reactor and furnace may create more reproducible results. Attempts at analyzing the kinetics of this reaction proved difficult. Results from x-ray diffraction produced impossible data. Further kinetics analysis should be performed once more reliable analysis can be achieved. Corrosion of calcium nitride by hydrogen to form ammonia The remaining solids after several reactions show a variety of compounds with varying ratios of calcium, nitrogen, and hydrogen. This could be an indication of a complex pathway to liberated nitrogen as ammonia with several intermediate steps. The composition of the remaining solids varies dramatically with temperature. At higher temperatures volatility of certain material can also change the solids’ composition, such as the calcium hydride. Calcium hydride apparently was able to vaporize and leave the system somewhere between 700 and 1000 °C. Preliminary results also indicate that ammonia production may level off after about 700 °C. That is why that temperature was chosen for the kinetics analysis. A key piece of data is that hydrogen flow rate has little or no effect ammonia production. This is an indicator of nature of the reaction. Diffusion appears to be the limiting portion of the reaction. This means that it is very difficult to speed the reaction up by methods that are not energy intensive. Also the calculations show that an increase in hydrogen flow rate adds extra separation energy requirements. Overall, some data shows promising results. promising. And some data is just plain bad. Some shows results that are not that