Candidates for Combined Heat and Power

advertisement

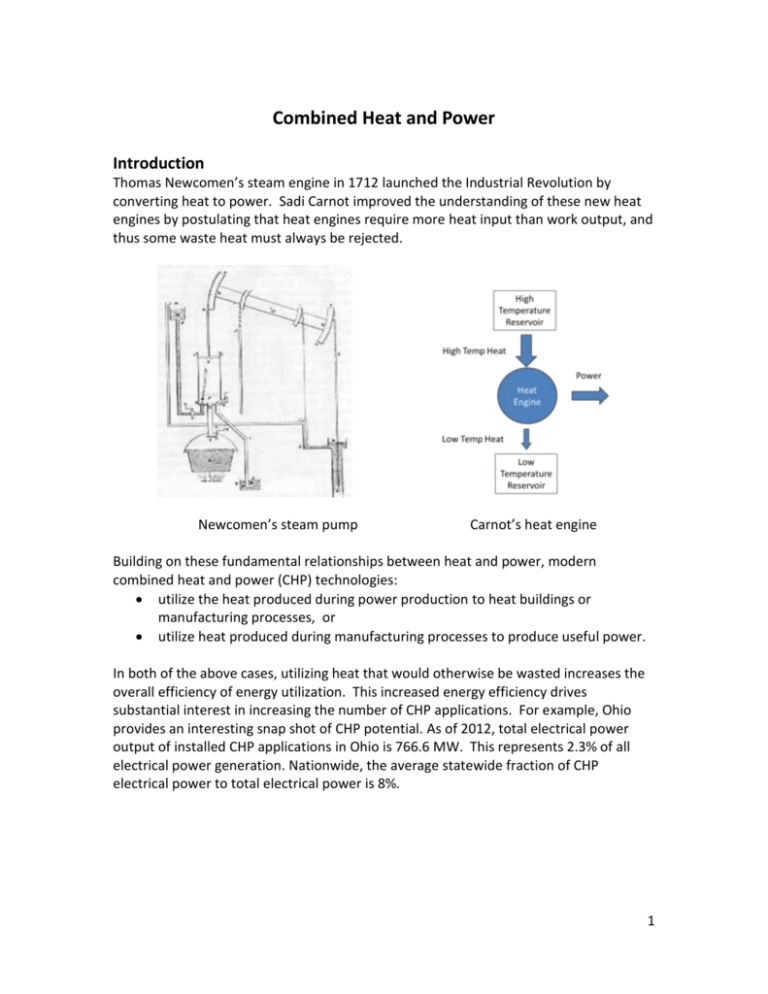

Combined Heat and Power Introduction Thomas Newcomen’s steam engine in 1712 launched the Industrial Revolution by converting heat to power. Sadi Carnot improved the understanding of these new heat engines by postulating that heat engines require more heat input than work output, and thus some waste heat must always be rejected. Newcomen’s steam pump Carnot’s heat engine Building on these fundamental relationships between heat and power, modern combined heat and power (CHP) technologies: utilize the heat produced during power production to heat buildings or manufacturing processes, or utilize heat produced during manufacturing processes to produce useful power. In both of the above cases, utilizing heat that would otherwise be wasted increases the overall efficiency of energy utilization. This increased energy efficiency drives substantial interest in increasing the number of CHP applications. For example, Ohio provides an interesting snap shot of CHP potential. As of 2012, total electrical power output of installed CHP applications in Ohio is 766.6 MW. This represents 2.3% of all electrical power generation. Nationwide, the average statewide fraction of CHP electrical power to total electrical power is 8%. 1 Source: Midwest Clean Energy Application Center www/midwestcleanenergy.org DOE estimates the technical potential of CHP to be 9,800 MW. Thus, in terms of technical potential, Ohio is rated as 5th. However, in terms of implementation, Ohio is rated as 43rd. 2 Candidates for Combined Heat and Power Cogeneration equipment is expensive and is seldom cost-effective for plants with small electrical and/or thermal loads. In addition, it is seldom economical for a plant to generate its own electricity unless the plant can also use the heat rejected from the electrical generation process. Moreover, because of the relatively high cost of cogeneration equipment, the equipment must run for most of the year in order to pay for itself. Finally, many electric utilities pay less for power generated by their customers than the charge for power sold to customers. Thus, cogeneration is typically most costeffective in applications where: • • • • the demand for both heat and electricity is substantial and nearly continuous all heat and electricity generated by the system can be used on site the cost of electricity is relatively high the cost of fuel is relatively low Sizing Combined Heat and Power Systems In most cases, electrical utilities can generate and sell electricity for less than the cost of purchasing and operating combined heat and power equipment. In these cases, combined heat and power equipment only generates net savings when both electricity and thermal output can be used. Further, combined heat and power equipment only generates the savings needed to pay for the investment when it is operating. Thus, except in special cases, combined heat and power systems should be sized based on a plant’s minimum electricity and heating requirements, so that the cogeneration system can run continuously at full capacity and all electrical and thermal energy can be utilized. Example A combined heat and power system has an electrical efficiency of 40%, and 60% of the waste heat can be used in a manufacturing process. Given the load profiles shown below for a manufacturing plant, determine the maximum size of the system so that all electrical and thermal power can be used. 3 The combined heat and power system can be modeled as shown below, where Qf is fuel input, Qw is waste heat, E is electrical output and Qu is useful heat. The electrical efficiency is Eff,e = E / Qf and the heat exchanger efficiency is Eff,hx = Qu / Qw1. 4 Qw2 Qu Eff,hx Qw1 Qf E Eff,e Combining energy balances and efficiency relations gives the following equation for Qu as in terms of E, Eff,e and Eff,hx: Qu = E Eff,hx (1 – Eff,e) / Eff,e (1) For the load profiles shown above, the maximum electrical power that can be utilized continuously is 50o kW. From Equation 1, the useable thermal power, Qu, from a CHP system with 50o kW electrical power is: Known E, Solve for Qu INPUTS Eff,e Eff,hx E (kW) 0.4 0.6 500 CALCULATIONS Qu (kW) = E Eff,hx (1-Eff,e) /Eff,e 450 Based on this calculation, at 500 kW of electrical power output, the useful thermal output would be 450 kW. However on a continuous basis, the plant can only use 30 kW of thermal power. Thus, useful power of 300 kW becomes the constraint. Solving Equation 1 for the electrical power output, E, at the useful thermal power constraint of 300 kW gives: 5 Known Qu, Solve for E INPUTS Eff,e Eff,hx Qu (kW) 0.4 0.6 300 CALCULATIONS E (kW) = Qu / [ Eff,hx (1-Eff,e)/Effe ] 333 Thus, the largest CHP system in which all the electrical and thermal power can be used is Emax = 333 kW and Qu,max = 300 kW. Types of CHP Systems Most CHP technologies fall into three categories: Steam to Power Power to Heat Heat to Power Steam-to-Power Systems Many manufacturing processes require large quantities of steam. In these cases, it may be economical to generate power from the steam before using it in the process. A typical steam-to-power cogeneration system employs a boiler to generate high-pressure steam. The high-pressure steam is fed into a turbine to generate shaft work. The shaft work drives an electrical generator and creates electrical power. Some (or all) of the steam is extracted from the turbine at a pressure high enough to be used in the plant. The rest of the steam may be extracted at less than atmospheric pressure, condensed and returned to the boiler. 6 Qcoal Make-up water Boiler Shaft work out Turbine Pump Condensor Electrical Generator Electricity Low-pressure steam ~ 50 - 150 psig steam to plant Qcondensor Steam turbine performance is typically characterized in terms of isentropic efficiency. The isentropic efficiency of a turbine is the ratio of actual energy output to maximum energy output from an isentropic turbine. Assume steam enters a turbine at statepoint (5) and exits the turbine at statepoint (6). In an ideal isentropic turbine with no internal friction or turbulence, the steam would exit the turbine at statepoint (6s), which has the same entropy as statepoint (5). Thus the isentropic efficiency, Effturbine, can be defined as: Effturbine = We,actual / We,max = ms (h5 – h6) / ms (h5 – h6s) = (h5 – h6) / (h5 – h6s) Thus, the enthalpy of steam exiting a turbine (6), can be determined from the entering enthalpy h5 and isentropic efficiency as: h6 = h5 – (h5 – h6s) x Effturbine According a back-pressure turbine manufacturers, packaged turbine/generator sets include the turbine, generator, skid, speed-reduction gears, controls and switch gear. The combined efficiency of the speed-reduction gear and the electrical generator is about 95%, and the cost of a turbine generator set is about $350 per kW. Example A large coal boiler produces 265,000 pounds per hour of saturated steam at 180 psig, for a large plant that operates 8,000 hours per year. The boiler is 80% efficient. The boiler feed water is a saturated liquid at 140 F. The boiler is capable of producing steam at up to 700 psig. This capability could be utilized to generate electricity while still meeting the process heating requirements of the plant. 7 Neglecting flash losses from the deaerator tank, calculate the annual additional cost of coal ($/year), annual electricity cost savings ($/year) and net annual savings ($/year) from producing 600-psig steam in the boiler and generating electricity from a backpressure turbine / generator set. The isentropic efficiency of a back-pressure turbine is 65%. The combined efficiency of the speed-reduction gear and the electrical generator is 95%. The cost of coal is $4.00 /mmBtu and the cost of electricity is $0.06 /kWh. Current System 2 Qexhaust Qfuel Deaerator Tank Process Heat Exchanger Boiler Qprocess 3 1 Steam Trap 4 Feed Water Pump Proposed System Qgen We 5 Turbine Ws Qexhaust Electrical Generator 6 Qfuel Deaerator Tank Boiler Process Heat Exchanger Qprocess 3 1 Steam Trap 4 Feed Water Pump 8 Current System The boiler feedwater (1) is a saturated liquid at 140 F. The steam leaving the boiler (2) is a saturated vapor at 195 psia. The boiler is 80% efficient. Thus, current fuel use is: Qf1 = ms x (h2 - h1) / Effboiler Qf1 = 265,000 lb/hr x (1,199 – 108) (Btu/lb) / 0.80 = 361 mmBtu/hr Assuming that heat to process is delivered through heat exchangers and the condensate leaves the heat exchanger (3) as a saturated liquid at 195 psia, the heat delivered to the process is: Qp= ms x (h2 – h3) Qp = 265,000 lb/hr x (1,199 – 353) Btu/lb = 224 mmBtu/hr Proposed System In the proposed system, steam would enter the turbine (5) as a saturated vapor at 615 psia. The isentropic efficiency of the turbine is 65%. Thus, the enthalpy of steam exiting the turbine (6), would be: h6 = h5 – (h5 – h6s) x Effturbine h6 =1,203 Btu/lb – (1,203 Btu/lb – 1,111 Btu/lb) x 65% = 1,143 Btu/lb The quality of the steam exiting the turbine (6) at 105 psia and this enthalpy would be about 93%. After passing through heat exchangers to deliver heat to process, 9 condensate leaves the process heat exchangers (7) as a saturated liquid at 195 psia. The quantity of steam required to produce the same quantity of process heat with steam exiting the turbine at this condition would be about: ms2 = Qp / (h6 - h7) ms2 = 224 mmBtu/hr / (1,143 Btu/lb – 353 Btu/lb) = 284,000 lb/hr The steam exiting the boiler (5) would be a saturated vapor at 615 psia with an enthalpy of about 1,203 Btu/lb. The quantity of fuel required to produce this quantity of steam would be about: Qf2 = ms2 x (h5 - h1) / Effboiler Qf2 = 284,000 lb/hr x (1,203 – 108) (Btu/lb) / 0.80 = 389 mmBtu/hr Net Savings The additional fuel for the boiler in the proposed system would be: dQf = Qf2 – Qf1 dQf = 389 mmBtu/hr – 361 mmBtu/hr = 28 mmBtu/hr The annual addition fuel and fuel cost would be about: dQf = 28 mmBtu/hour x 8,000 hour/year = 224,000 mmBtu/year dCf = 224,000 mmBtu/year x $4.00 /mmBtu = $896,000 /year The combined efficiency of the speed-reduction gear and the electrical generator is 95%. Thus, the electrical output produced by the turbine / generator would be: We = ms2 x (h5 - h6) x Effgen We = 284,000 lb/hr x (1,203 Btu/lb -1,143 Btu/lb) x 95% / 3,413 Btu/kWh = 4,743 kW The annual electricity and electricity cost savings would be about: We = 4,743 kW x 8,000 hour/year = 37,944,000 kWh/year Ce = 37,944,000 kWh/year x $0.06 /kWh = $2,276,640 /year The net annual cost savings would be about: $2,276,640 /year - $896,000 /year = $1,380,640 /year Simple Payback Turbine/generator sets typically include the turbine, generator, skid, speed-reduction gears, controls and switch gear, and cost about $350 per kW. If shipping and installation doubles the purchase cost, the total installed cost of a 5,000 kW system would be about: 10 [(5,000 kW x $350 /kW)] x 2 = $3,500,000 The simple payback would be: $3,500,000 / $1,380,640 /year x 12 months/year = 30 months The overall thermal efficiency of the system, Effthermal, is: We = 4,743 kW x 3,413 Btu/kWh / 1,000,000 Btu/mmBtu = 16 mmBtu/hr Effthermal = (We + Qp) / Qf2 Effthermal = [16 mmBtu/yr + 224 mmBtu/hr] / 389 mmBtu/hr = 62% Power to Thermal Energy Systems Power-to-thermal energy systems typically employ a gas turbine, diesel engine or fuel cell to generate electrical power. The waste heat from the power generation device is then directed to a boiler or heat exchanger which converts the waste heat into useful heat for the plant. Utilizing Heat from Exhaust Gasses A common method to utilize the heat from the hot exhaust gasses from a gas turbine or diesel engine is to generate steam or hot water. Standard steam boilers are designed to use high-temperature (~3,000 F) combustion gasses at relatively low flow rates. The exhaust gas from a turbine is typically at much lower temperatures (600 – 1,000 F) and higher flow rates. Thus, it is advisable to purchase a specially designed boiler for most cogeneration systems. “Waste heat” boilers usually typically have the capacity for supplemental heating to provide steam when the turbine is not operating and to boost the temperature of the exhaust gasses. The cost of cogeneration boilers is typically about $15 per pound of steam per hour. The quantity of useful heat reclaimed by a waste heat boiler, Qu, can be calculated as: Qu = mex x cpex x (Tex from turbine/engine – Tex from boiler) where the exhaust mass flow rate, mex, and temperature, Tex from turbine, are typically given as turbine performance specifications. The specific heat of natural gas exhaust, cpex, is about 0.26 Btu/lb-F. 11 Gas Turbines A typical gas turbine cogeneration system is shown below. Ambient air is compressed to a high pressure, then heated to further raise the pressure. The hot, high pressure air is then expanded through a turbine and discharged to ambient at between 600 F and 1,000 F. The shaft work generated by the turbine is sufficient to power the compressor and turn an electrical generator. The generator set typically includes a speed reduction gear and power conditioning equipment so that the electrical power output is threephase AC power that can be fed directly into the plant. Qnatural gas Combustor Shaft work out Shaft work to compressor Compressor Electrical Generator Turbine Electricity Exhaust at ~375 F Turbine exhaust at 650 – 1,000 F Ambient air Steam Boiler Significantly higher efficiency can be achieved by adding a recuperator to pre-heat air entering the combustor from the hot exhaust gasses. A schematic of a turbine generator set with recuperator is shown below. Exhaust Out Air In Heat Exchanger Natural Gas In Burner Turbine Shaft Compressor Shaft Electricity Out Electrical Generator In CHP systems, it is sometimes useful to designate electrical power output from the generator with unit kWe and shaft power output from the turbine with unit kW. Nominal performance data from turbine generator sets are shown in the table below. Nominal performance data were taken at standard conditions of sea level air at 59 F. Turbine efficiency and power output degrade at higher elevations and as the inlet air temperature increases. In addition, turbine efficiency also declines when the turbines 12 are operated at less than rated output. Gas turbine lifetime is indefinite with proper maintenance because maintenance includes replacement parts. Typical maintenance costs are about $0.004 /kWh. Saturn 20 Centaur 40 Mercury 50 Electrical Output 1,210 kWe 3,515 kWe 4,600 kWe Heat Rate 14,025 Btu/kWhe 12,245 Btu/kWhe 8,863 Btu/kWhe Exhaust Flow 51,890 lb/hr 150,715 lb/hr 140,400 lb/hr Exhaust Temp 940 F 830 F 710 F Source: www.mysolar.cat.com The electrical efficiency of the turbines is given by the reciprocal of the heat rate. The Mercury 50 turbine employs a recuperator to preheat air to the burner and has a significantly lower heat rate. The electrical efficiency of the Saturn 20 and Mercury 50 turbine generator sets are about: EffSaturn20 = 1 / Heat rate = (1 / 14,025 Btu/kWh) x 3,412 Btu/kWh = 24% EffMercury50 = 1 / Heat rate = (1 / 8,863 Btu/kWh) x 3,412 Btu/kWh = 38% Εxample A turbine generator set has the following performance data. Electrical Output: Heat Rate: Exhaust Flow: Exhaust Temp: 4,162 kWe 8,544 Btu/kWhe 136,000 lb/hr 663 F Calculate the thermal output at 100% load, the energy recoverable by directing exhaust gasses through a heat recovery boiler, and the overall thermal efficiency. The exhaust gasses leave the boiler at 375 F. The fuel energy input, Qf, at 100% load is: Qf = 4,162 kW x 8,544 Btu/kWh = 35.56 mmBtu/hr The electrical energy output, We, at 100% load is: We = 4,162 kW x 3,412 Btu/kWh x 1 mmBtu/ 106 Btu = 14.20 mmBtu/hr The specific heat of the exhaust air is 0.26 Btu/lb-F. The temperature of the exhaust leaving a cogeneration boiler is 375 F. The useful energy to the steam, Qu, is: 13 Qu = m cp (Texhaust,turbine – Texhaust,boiler) Qu = 136,000 lb/hr x 0.26 Btu/lb-F x (663 – 375) F = 10.18 mmBtu/hr The overall thermal efficiency of the system, Effthermal, is: Effthermal = (Welec + Qu) / Qf Effthermal = [14.20 mmBtu/hr + 10.18 mmBtu/hr] / 35.56 mmBtu/hr = 69% Micro Turbines Micro turbines with integrated electrical generators with electrical power output ranging from 30 kW to 200 kW are also available. Multiple micro turbines can be staged in applications with variable loads to reduce part load efficiency losses. A 65-kW microturbine may use 0.84 mmBtu per hour of natural gas at full load and discharge 600 scfm of exhaust air at 800 F. 30 kW micro turbine www.capstonemicroturbine.com Reciprocating Engines Reciprocating engines fueled by natural gas or diesel fuel can be coupled to electrical generators as shown below. These engines range in size from about 10 kWe to 20 MWe. 14 Diesel engine with electrical generator set. Source: www.cat.com. Heat is rejected from reciprocating engines through several pathways. An approximate breakdown of heat loss from a diesel powered electrical generation set is shown below. In general, heat loss from the hot surfaces of the engine and generator is difficult to reclaim. Heat loss in the exhaust and coolant is easier to reclaim, however the maximum temperature of the coolant is generally so low (~ 120 F) that it limits heat reclaim possibilities. Heat rejection from a diesel generator set at full load (from www.cat.com) Heat rejection to coolant (total) Heat rejection to exhaust (total) Heat rejection to after cooler Heat rejection to atmosphere from engine Heat rejection to atmosphere from generator 21% 52% 11% 12% 3% Example: An 830 kWe diesel generator set consumes 57.6 gal/hr of fuel, produces 6,397cfm of exhaust at 847 F. Calculate the rate of useful heat that can be reclaimed from the exhaust if the exhaust leaves a heat reclaim heat exchanger at 400 F. Calculate the total thermal efficiency of the system. The product of the density and specific heat of exhaust gasses is about 0.018 Btu/lb-F and the energy content (HHV) of diesel fuel is 130,500 Btu/gal. The rate of useful heat that can be reclaimed from the exhaust, Qu, if the exhaust is: INPUTS V (cfm) pcp (Btu/ft3-F) Tex1 Tex2 CALCULATIONS Qu (Btu/hr) = V pcp (Tex1 - Tex2) 60 Qu (kW) = Qu (Btu/hr) / 3,412 6397 0.018 847 400 3,088,216 905 The fuel energy input, Qf, and total thermal efficiency Eff,thermal, are: 15 INPUTS Vf (gal/hr) HHV (Btu/gal) We (kW) CALCULATIONS Qf (Btu/hr) = Vf HHV Qf (kW) = Qf (Btu/hr) / 3,412 Eff,thermal = (We + Qu) / Qf 57.6 130,500 830 7,516,800 2,203 0.79 Gas-Fired Reciprocating Engines: Gas-fired reciprocating internal combustion engines offer many advantages over other technologies for small scale CHP such as low capital cost, easy start-up, high reliability, good load-following characteristics, less expensive backup power, and the ability to generate onsite power during peak demand periods. Commercially available natural gas reciprocating engines produce from 0.5 kW to 10 MW of electrical power. Natural Gas Fired Reciprocating Engine. Source: http://www.allforpower.com Heat can be recovered from the exhaust gas, intercooling stages, lube oil and jacket water. Heat loss from the hot surfaces of the engine and generator is difficult to reclaim. Specifications of a typical natural gas-fired reciprocating engine are shown in the following table. At full load, 41.5% of fuel energy is converted into electrical power and 44.8% into useful recoverable heat. Thus, the total efficiency is 86.3%. 16 Technical Data Full Load (100%) Medium Load (75%) Low Load (50%) 14.73 11.38 8.04 1.70 1.31 0.93 2.51 1.88 1.26 1.79 1.33 0.88 Recoverable Thermal Output Intercooler first stage (kBtu/hr) 1.34 0.75 0.22 Lube oil (with gearbox) (kBtu/hr) 0.71 0.63 0.55 Jacket water (kBtu/hr) 1.06 0.90 0.78 Exhaust gas cooled to 248 F (kBtu/hr) 3.49 2.96 2.28 Total Recoverable Thermal Output (kBtu/hr) 6.60 5.25 3.83 Efficiencies Electrical Efficiency 41.5% 39.8% 37.3% Thermal Efficiency 44.8% 46.1% 47.7% Total Efficiency 86.3% 85.9% 85.0% Hot Water Circuit Forward Temperature (F) 194 170 167 Return Temperature (F) 158 158 158 Hot water flow rate (gpm) 367 367 367 Parameter (units) Energy Input (kBtu/hr) Gas Volume (scfhr) Mechanical Output (bhp) Electrical Output (kW) Mass flow rates on combustion air and exhaust gases and temperature of the exhaust are shown in the following table. This information can be used to determine the amount of energy that can be recovered from the exhaust gas stream. Combustion Air and Exhaust Gas Data Parameter Value Units Combustion air mass flow rate 22.6 lbs/hr Exhaust Gas temperature at full load 804 F Exhaust Gas Mass flow rate (wet) 23.3 lbs/hr Exhaust Gas Mass flow rate (dry) 21.8 lbs/hr Exhaust gas volume, wet 310.4 scfhr Exhaust gas volume, dry 280.4 scfhr Example: A natural gas reciprocating engine consumes 1.7 scfm/hr of natural gas at full load, and produces 23 lbs/hr of exhaust at 804 F. A facility receives city water at an average annual temperature of 60 F and is considering installing an 80% effective counter flow heat exchanger to produce hot water. Assuming the mass flow rate of water is the same as the exhaust gas, what would be the temperature of exiting hot water and the amount of energy recovered through the heat exchange process? The specific heats of the exhaust gas and water are about 0.26 Btu/lb-F and 1.0 Btu/lb-F respectively. 17 HX WITH KNOWN EFFECTIVENESS INPUTS Term Value Incoming Hot Fluid Temperature, Th1 Hot Fluid Mass Flow Rate, mh Hot Fluid Specific Heat, cph Incoming Cold Fluid Temperature, Tc1 Cold Fluid Mass Flow Rate, mc Cold Fluid Specific Heat, cpc Heat Exchanger Effectiveness, e Units 804 F 0.4 lb/min 0.26 Btu/lb-F 60 F 0.4 lb/min 1 Btu/lb-F 80% CALCULATIONS Term Hot Fluid Heat Capacity, Ch = mh * cph Cold Fluid Heat Capacity, Cc = mc * cph Cmin = min(Ch,Cc) Cmax = max(Ch,Cc) Heat Transfer, Q = e*Cmin*(Th1-Tc1) Exiting Hot Fluid Temperature, Th2 = Th1-Q/Ch Exiting Cold Fluid Temperature, Tc2 = Tc1 + Q/Cc Heat Transfer, Q Value Units 0.1 Btu/min-F 0.4 Btu/min-F 0.1 Btu/min-F 0.4 Btu/min-F 59 Btu/min 209 F 208 F 3,559 Btu/hr Incoming and outgoing temperatures of both exhaust (Th1, Th2) and water (Tc1, Tc2) are shown in the following diagram. 804 F Th1 Tc2 208 F Tc1 60 F Qact 209 F Th2 Heat to Power Rankine power cycles use heat to make electrical power. In traditional Rankine systems, the working fluid is water. At atmospheric pressure water boils at 212 F, and the boiling temperature increases at the higher pressures that generate more work; thus steampowered Rankine cycles require relatively high temperature heat to be effective. In contrast, refrigerants boil at much lower temperatures than water. Thus, Rankine cycles using refrigerant as the working fluid are able to generate power using much 18 lower temperature heat. These systems are sometimes called “organic Rankine systems” with reference to the organic nature of the refrigerants. Many industrial plants generate large quantities of relatively low-temperature waste heat. In these cases, low-temperature heat-to-power systems can use the heat to generate electrical power. Low-temperature organic Ranking cycle. Source: www.transpacenergy.com An organic Rankine system that uses heat reclaimed from exhaust gasses is shown in the figure below. Heat is reclaimed from hot exhaust by an air-to-liquid heat exchanger. The hot liquid leaves the heat exchanger at 265 C and vaporizes refrigerant in the vaporizer. The vapor is expanded by a turbine, producing shaft work that drives an electrical generator. The warm low-pressure vapor leaving the turbine delivers some heat to the low-temperature refrigerant before being condensed in an air-cooled condenser. A pump increases the pressure of the low temperature fluid, before it picks up heat from the hot vapor leaving the turbine. The fluid then returns to the vaporizer and the cycle is repeated. 19 Source: Muller, M. “Organic Rankine Cycles”, IAC Director’s Meeting, San Francisco, CA, 2010. Another system is shown below. This system can use heat at a temperature as low as 121 C, and an evaporative cooler instead of an air cooler to condense the working fluid. The system use R245fa as the working fluid. 20 Source: Muller, M. “Organic Rankine Cycles”, IAC Director’s Meeting, San Francisco, CA, 2010. Self-contained modular organic Rankine power systems are now on the market. System sizes ranges from about 10 kW to about 300 kW. Typical systems can use hot water in the 190 F range or exhaust gasses in the 400 F range. Typical installed system cost is about $2,500 per kWe. Example A modular organic Rankine system costs $2,500 /kW and generates 50 kW of electrical power 8,000 hours per year. If the electricity generated by the system displaces electricity purchased from a utility at $0.10 /kW, calculate the simple payback of the system. Cost savings = 50 kWe x 8,000 hr/yr x $.10 /kWh = $40,000 /year Implementation cost = 50 kW x $2,500 /kW = $125,000 Simple payback = $125,000 / $40,000 /year = 3.125 years 21