TANWAT POWER STATION (case study)

advertisement

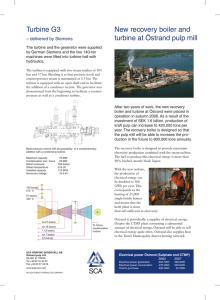

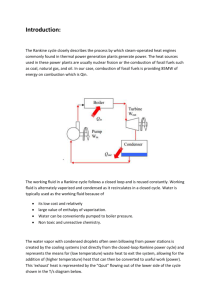

TANWAT POWER PLANT (case study) Rabiel Ulomi Power station Manager 2. BACKGROUND 2.1 Establishment of Tanwat: Tanganyika wattle company (Tanwat) derives its name from the wattle tree (acacia mearnsii) from which a form of tannin known as mimosa extract used in leather industry is processed. The company was founded in 1949 by Commonwealth Development Corporation (CDC) by gradual establishment of over 15,000 hectors of sustainable forest . Only bark which makes up about 20% of the bulk is processed leaving behind the rest as waste. 2.2 Core business. Tannin continued to be Tanwat’s major revenue source until late 1960’s when decline in demand for leather goods brought about by availability of cheaper synthetic alternatives resulted in initiatives to explore for new forest products for long term future prospects. 2.3 Diversification • Years 1970 – 1980’s explore new global business opportunities. • Arable crop farming • Tea business • Power business THE PLANT 3.2 Description of major equipments 3.2.1 Boilers (2units) (1Unit) Make: Titan towler, Made by Mechmar of Malaysia German Type: Water tube Rated output::15 tonnes per hr each 300X650L-6WT Operating pressure: 30 bars Steam temperature : 330 deg c 3.2.2 Steam turbine Make: Dresser Rand, USA Type :Condensing Terry turbine Capacity: 2500kw Rotor : speed 5345 RPM 3.2.3 Chipping Plant Make: Klockner, Type : Drum chipper Model:KTH 3.2.4 Generator Make : AVK , Germany Rated Cap: 3125 Kva Rated Terminal V: 3300 v Rated frequency : 50 Hertz 4.2 PROCESS 4.2.1 FUEL -De-barked wattle logs (acacia mearnsii), Eucalyptas logs and saw mill wastes are chipped into small size 25 X 25 mm and conveyed to silos for storage from which they are fed into boiler furnaces at a rate proportional to energy requirement at the material time. 4.2.2 STEAM- Raw water which is only used as make up is passed through a cat-ion exchange water softener and comes out as soft water. It is mixed with condensate before being pump to thermal deaerator and finally into the boilers. Steam coming out is superheated steam at a temperature between 300- 3300C. Part of the steam is directed to the prime mover, a condensing turbine for power generation and the rest is desuperheated for using in the bark processing plant and sawn timber dry kiln. 5 PLANT MAINTENANCE 5.1 Preventive maintenance Direct Indirect/condition monitoring -Cleaning -temperature measurement -Lubrication, -vibration tests -Programmed -abnormal sound replacement/overhaul 5.2 Planned shut down maintenance -Done once or twice a year mainly with the purpose of cleaning cooling and feed water systems or do major replacement on chipping plant/conveying system and turbo alternator lubricating system. -The maintenance is usually carried out for a period of less than 12 hrs -The customers are issued with a one week notice. Safety • Developed safety procedures and well defined activity procedures. • RIAR- a performance target for staff. 5.3 Annual legal inspection • The inspection is carried out on boilers, high pressure vessels, and lifting tackles. • Boiler inspection involves, physical inspection, hydraulic test and steam test. • Pressure vessels inspection involves wall thickness measurements and relieve valves testing. • • The inspection is done by authorized Government inspector. ENERGY DISTRIBUTION 6.1Steam distribution 6.2 Power distribution. • Tanesco interconnector- through 2000kva, 3300/33000 V transformer • Power station own consumption-through 1000kva 3300/415V transformer • Wattle factory/sawmill supply-through 1000kva 3300/415v transformer. • Kibena tea factory supply-through 2000kva 3300/11000V transformer. 7. CHALLENGES 7.1 Pollution of environment with boiler grits. Solution: installed a grit arrestor on the flue gas line. 7.2 Monitoring boiler operating parameters 1) Boiler water level-lost one boiler in 1996 due loss of water Solution: Intensive training on boiler emergency shut down procedure. 2) Steam temperature control-due lack of attemperator to stabilize super heated steam temperature. Solution:1) Training on how reduce steam temp. manually using super heater drain valve. 2) An alarm was installed to give a warning once temperature exceeds 330 deg cent. 7.3 Copping with earth faults and lightning • Njombe climate favours trees growth. This falls on power lines frequently especially during rain season causing earth faults and turbine tripping. Soln. 1) Removal of all the trees close to and leaning towards power lines. 2) Staff trained to do a quick reset before the turbine slows down. 7.4 Breakdown of major equipments and lack of standby units. -eg chipping plant, turbine, and alternator Sonl. 1) Emphasis on preventive maintenance. . 2) Maintaining adequate stocks of spare parts and material. 7.5 Lack of skilled labour The expansion of primary and secondary education in Tanzania, growing industrial an mining sectors have created very high demand for technical personnel in the recent past. Soln.1) Intensive in house training and promotions 2) Improved remuneration package 4. PLANT OPERATIONS 4.1 Organization Structure Power Station Manager Senior Engineer Shift Engineer 4 Boiler Technician-4 Turbine Technician -4 Electrical Techchnician-4 Boiler operator -4 Boiler assistants- 4 Chipper Operator -4 Chipper Attendant - 8 General staff -3 ACHIEVEMENT • • • • • • Smooth operation for almost 14 yrs. Experience & Knowledge. High availability. Cheap and reliable power source. Better resource utilization. Positive contribution towards reduction of environmental pollution. FUTURE (bright) • The Government of Tanzania encouraging producers through small power purchase agreement. • Availability of biomass • Tanwat plan to install a 5 Mw plant soon and a 15 Mw plant in the near future. • Kyoto protocol-carbon credits.