Problem set #1

advertisement

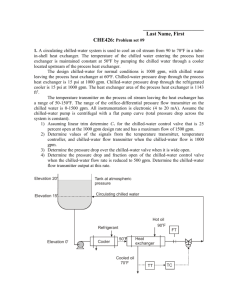

_______________________ Last Name, First CHE426: Problem set #8 1. Determine the open loop response of three ideal CSTRs in series when the inlet concentration of A, CA0, changes from 0.8 to 1.8 kmol/m3. The reaction is first order with reaction rate constant k = 0.5 s-1. The tank volume V is 0.10 m3 and the liquid flow rate F is 0.05 m3/s. F F V CA0 F V CA1 F V CA2 CA3 Use Laplace transform to solve for the deviation concentration in each tank as a function of time. Plot the deviation concentrations for three tanks for 0 t 4 s and use the Title command to label the graph with your name. 2.1 The overhead vapor from a depropanizer distillation column is totally condensed in a water-cooled condenser at 120oF and 227 psig. The vapor is 95 mol % propane and 5 mol % isobutene. The vapor design flow rate is 25,500 lb/h and average latent heat of vaporization is 125 is 125 Btu/lb. Cooling water inlet and outlet temperatures are 80 and 105oF, respectively. The condenser heat transfer area is 1000 ft2. The cooling water pressure drop through the condenser at design rate is 5 psi. A linear-trim control valve is installed in the cooling water line. The pressure drop over the valve is 30 psi at design with the valve half open. The process pressure is measured by an electronic (4-20 mA) pressure transmitter whose range is 100-300 psig. An analog electronic proportional controller with a gain of 3 is used to control process pressure by manipulating cooling water flow. The electronic signal from the controller (CO) is converted into a pneumatic signal in the I/P transducer. a) Calculate the cooling water flow rate (gpm) at design conditions. Water density is 62.3 lb/ft3 and 1 ft3 = 7.48 gal. b) Calculate the size coefficient (Cv) of the control valve. c) Calculate the values of the signals PM, CO, SP, and PV at design conditions. d) Suppose the process pressure jumps 10 psi. How much will the cooling water flow rate increase? Determine values for PM, CO, SP, and PV at this higher pressure. Assume that the total pressure drop over the condenser and control valve is constant at 35 psi. Vapor Cooling water Control valve Condenser PV I/P Reflux drum PT PM PC CO SP 3. Consider a well-mixed tank with a water steady flow rate F of 200 L/min. The volume of water in the tank is 1,000 L. The inlet water temperature is 60oC. The system is at steady state with heat input sufficient to heat the outlet water temperature to 80oC. Suddenly the inlet temperature experiences a step change from 60oC to 70oC. The thermocouple measuring the tank temperature has a first order transfer function relating the measured temperature Tmd to Ti the actual temperature Td(s) in the tank according to F Tmd ( s) 1 = 0.33s 1 T d ( s) F T Heat input q Determine the closed loop response of the tank temperature if the tank has a negative feedback system with proportional gain KC = 20. a) Obtain an expression for Td(t) and plot the response from 0 to 20 minutes using Matlab with your name printed on the graph. b) Use simulink to obtain the response and compare with the results in part (a). 4.2 Consider a manometer as illustrated below. The manometer is being used to determine the pressure difference between two instrument taps on an air line. The working fluid in the manometer is water. Determine the response of the manometer to a step change in pressure across the legs of the manometer for the cases when the inside tube diameter are 0.10 cm, 0.20 cm, and 0.35 cm. Data: manometer fluid length, L = 250 cm; g = 981 cm2/s; = 0.0097 g/cms, = 1.2 g/cm3. for t < 0 P 0 g 10 cm for t 0 a) Obtain the equation in time domain and plot the response using Matlab. Label the graph with your name using the title command. b) Use simulink to obtain the response. Label the pressure step forcing function on the simulink model with your name. Turn in the simulink model and the graph from simulink. Label the graph with your name. P1 = 0 P2 = 0 P1 P2 h Initial Reference level Final 5.2 A pneumatic PI temperature controller has an output pressure of 10 psig when the set point and process temperature coincide. The set point is suddenly increased by 10oF (i.e. a step change in error is introduced), and the following data are obtained: Time, s psig 010 0+ 8 20 7 60 5 90 3.5 Determine the actual gain (psig/oF) and the integral time. 6.1 A circulating chilled-water system is used to cool an oil stream from 90 to 70oF in a tubein-shell heat exchanger shown. The temperature of the chilled water entering the process heat exchanger is maintained constant at 50oF by pumping the chilled water through a cooler located upstream of the process heat exchanger. The design chilled-water for normal conditions is 600 gpm, with chilled water leaving the process heat exchanger at 65oF. Chilled-water pressure drop through the process heat exchanger is 15 psi at 800 gpm. Chilled-water pressure drop through the refrigerated cooler is 15 psi at 800 gpm. The temperature transmitter on the process oil stream leaving the heat exchanger has a range of 40-180oF. The range of the orifice-differential pressure flow transmitter on the chilled water is 0-1500 gpm. All instrumentation is electronic (4 to 20 mA). Assume the chilled-water pump is centrifugal with a flat pump curve (total pressure drop across the system is constant). The control valve has a linear trim with Cv = 128.81 gpm/psi0.5. The valve is 40 percent open at the 800 gpm design rate and has a maximum flow of 1500 gpm. Elevation 20' Tank at atmospheric pressure Elevation 15' Circulating chilled water Hot oil 90oF Refrigerant FT o Elevation 0' Cooler 50 F Cooled oil o 70 F Heat exchanger TT TC a) Determine the total pressure drop through the system. b) Determine the pressure drop through the cooler and the heat exchanger at maximum flow rate. c) Determine the value of the signal from the temperature transmitter. d) Determine the value of the signal from the flow transmitter. e) If Cv = 200 gpm/psi0.5 and the total pressure drop through the system is 200 psi, determine the fraction open of the chilled-water control valve when the chilledwater flow rate is reduced to 600 gpm. _ 7. A tank is heated by steam condensing inside a coil. A PID controller is used to control the temperature in the tank by manipulating the steam valve position. Process. The feed has a density of 68.0 lb/ft3 and a heat capacity cp of 1.0 Btu/lboF. The volume V of liquid in the reactor is maintained constant at 200 ft3. The coil consists of 300 ft of 4-in. schedule 40 steel pipe with outside diameter of 5 in. The overall heat transfer coefficient U, based on the outside are of the coil, has been estimated as 2.0 Btu/minft2oF. It can be assumed that its latent heat of condensation of saturated steam is constant at 950 Btu/lb. It can also be assumed that the inlet temperature Ti is constant. Design Conditions. The feed flow F at design condition is 20 ft3/min, and its temperature Ti is 100oF. The contents of the tank must be maintained at a temperature T of 150oF. (a) Determine the steam temperature at the design condition. (b) If the steam temperature at the design condition is 250oF, determine the steam flow rate in lb/min. 8. A thermometer having a time constant of 1 min is initially at 50oC. It is immersed in a bath maintained at 150oC at t = 0. Determine the temperature reading at t = 1.5 min. 9. A thermometer having a time constant of 0.5 min is placed in a temperature bath, and after the thermometer comes to equilibrium with the bath, the temperature of the bath is increased linearly with time at a rate of 10oC/min. Determine the difference between the indicated temperature and the bath temperature after 20 s. References 1. Process Modeling, Simulation, and Control for Chemical Engineers by Luyben 2. D.R. Coughanowr and S. LeBlanc, Process Systems Analysis and Control, McGrawHill, 3nd edition, 2008.