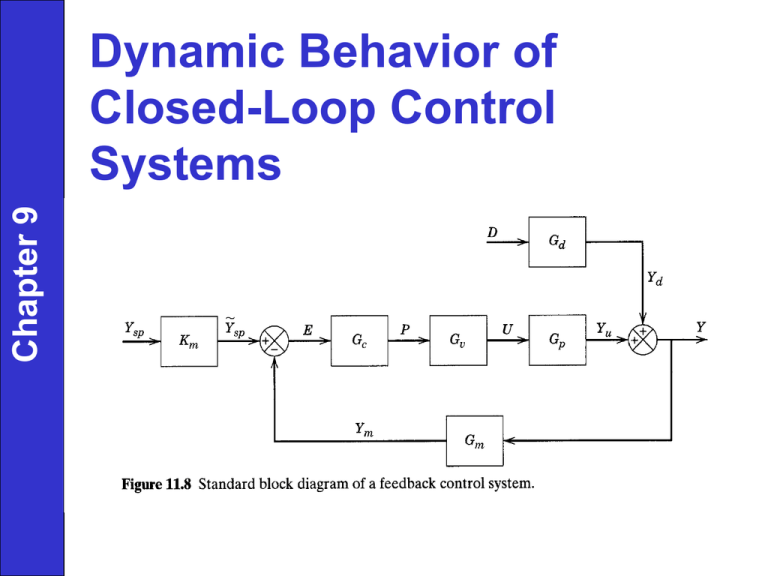

Chapter 9 - Department of Chemical Engineering

advertisement

Chapter 9 Dynamic Behavior of Closed-Loop Control Systems Chapter 9 Control System Instrumentation Figure 9.3 A typical process transducer. Transducers and Transmitters • Figure 9.3 illustrates the general configuration of a measurement transducer; it typically consists of a sensing element combined with a driving element (transmitter). • Since about 1960, electronic instrumentation has come into widespread use. Sensors Chapter 9 The book briefly discusses commonly used sensors for the most important process variables. (See text.) Transmitters • A transmitter usually converts the sensor output to a signal level appropriate for input to a controller, such as 4 to 20 mA. • Transmitters are generally designed to be direct acting. • In addition, most commercial transmitters have an adjustable input range (or span). • For example, a temperature transmitter might be adjusted so that the input range of a platinum resistance element (the sensor) is 50 to 150 °C. Chapter 9 Chapter 9 Instrument Selection Criteria •solid/gas/liquid, corrosive fluid •nature of signal, speed of response •accuracy, measurement range •costs •previous plant practice •available space •maintenance, reliability •materials of construction •invasive/non-invasive •environmental/safety (enclosures, fugitive emissions) Chapter 9 Chapter 9 Transmitter/Controller May need additional transducers for Gm if its output is in mA or psi. In the above case, Gc is dimensionless (volts/volts). Chapter 9 Chapter 9 Figure 9.15 Nonideal instrument behavior: (a) hysteresis, (b) deadband. Chapter 9 Chapter 9 Chapter 9 Measurement / Transmission Lags Chapter 9 • Temperature sensor TM (s) 1 T(s) s + 1 m s Cs = Us As make as small as possible (location, materials for thermowell) • Pneumatic transmission lines usually pure time delay, measure experimentally (no time delays for electronic lines); less common today compared to electronic transmissions. Chapter 9 Chapter 9 Chapter 9 Chapter 9 from Riggs, J.B., Chemical Process Control Numbers in table above correspond to Cvf(l), dp in psi, q in gal/min, and gs is specific gravity: Three valve characteristics determined by plug shape: (1) Quick Opening (square root trim) Chapter 9 f s s fractionopenof thevalve(0 s 1) (2) Linear Trim f s (3) Equal Percentage f s1 slope ~ f 20 - 50 must take other flow obstructions into account for actual valve performance Chapter 9 See Example 9.2 Chapter 9 Suppose valve has linear trim and flow must be changed. If p through exchanger does not change, valve would behave linearly (true for low flow rates), since it takes most of p . For lower flow rates, p through exchanger will be reduced, changing effective valve characteristics (valve must close more than expected nonlinear behavior). Equal % in this case behaves more like linear valve. Size pvalve = 25% total p , at s=50% (Δp→$) valves need to operate between 5% and 95%, flow ~ ΔPvalve Chapter 9 Chapter 9 Failure philosophy: Keep process pressure low, protect environment (equipment and engineers) Chapter 9 A-O F / C A-C F / O Pneumatic control valves are to be specified for the applications listed below. State whether an A-O or A-C valve should be specified for the following manipulated variables: (a) (b) (c) (d) Steam pressure in a reactor heating coil. Flow rate of reactants into a polymerization reactor. Flow of effluent from a wastewater treatment holding tank into a river. Flow of cooling water to a distillation condenser. Chapter 9 Previous chapter Next chapter