Set 4

advertisement

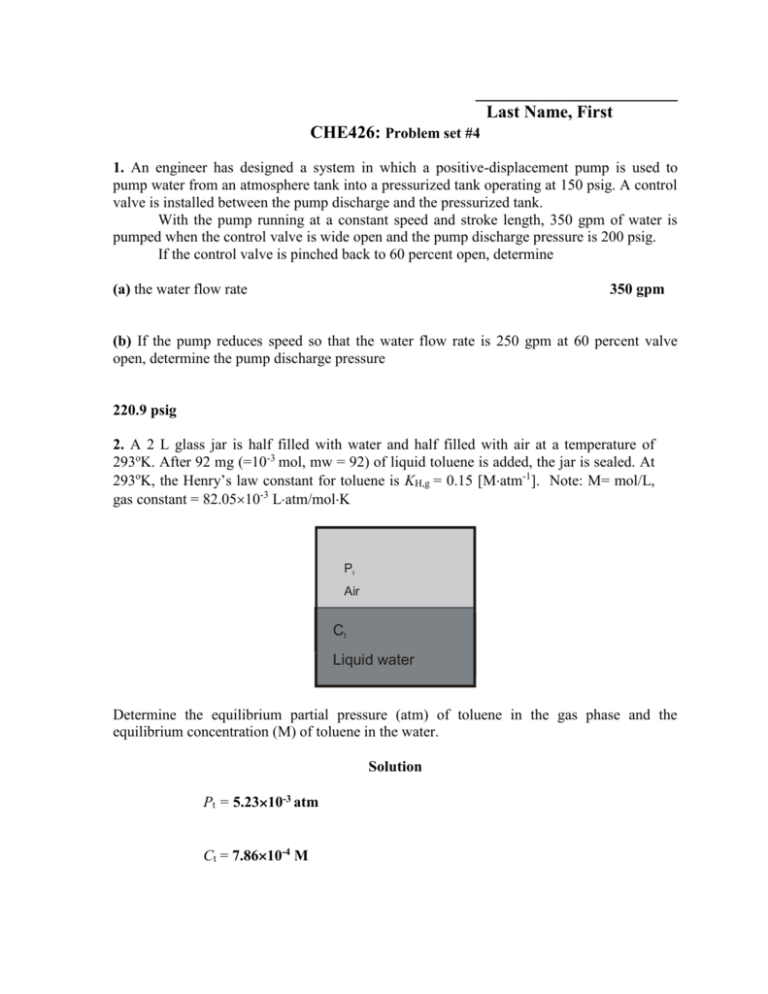

_______________________ Last Name, First CHE426: Problem set #4 1. An engineer has designed a system in which a positive-displacement pump is used to pump water from an atmosphere tank into a pressurized tank operating at 150 psig. A control valve is installed between the pump discharge and the pressurized tank. With the pump running at a constant speed and stroke length, 350 gpm of water is pumped when the control valve is wide open and the pump discharge pressure is 200 psig. If the control valve is pinched back to 60 percent open, determine (a) the water flow rate 350 gpm (b) If the pump reduces speed so that the water flow rate is 250 gpm at 60 percent valve open, determine the pump discharge pressure 220.9 psig 2. A 2 L glass jar is half filled with water and half filled with air at a temperature of 293oK. After 92 mg (=10-3 mol, mw = 92) of liquid toluene is added, the jar is sealed. At 293oK, the Henry’s law constant for toluene is KH,g = 0.15 [Matm-1]. Note: M= mol/L, gas constant = 82.0510-3 Latm/molK Pt Air Ct Liquid water Determine the equilibrium partial pressure (atm) of toluene in the gas phase and the equilibrium concentration (M) of toluene in the water. Solution Pt = 5.2310-3 atm Ct = 7.8610-4 M 3.2 We want to design a control valve for admitting cooling water to a cooling coil in an exothermic chemical reactor. The normal flow rate is 60 gpm and the minimum flow rate is 25 gpm. To prevent reactor runaways, the valve must be able to provide three times the design flow rate. The pressure drop through the cooling coil is 5 psi at the design flow rate of 60 gpm. The cooling water is pumped from an atmospheric tank. The water leaving the coil run into a pipe in which the pressure is constant at 2 psig. Size the control valve and the pump. Solution Cv = 26.12 gpm/psi0.5 and PT = 92.5 psig. The pump head is then PP = PT +2 = 94.5 psi. 4.2 A process for transferring oil from a storage tank to a separation tower is shown in Figure P-5b. The tank is at atmospheric pressure, and the tower works at 12.7 psia. Nominal oil flow is 1000 gpm, its specific gravity is 0.90, and its vapor pressure at the flowing temperature of 90oF is 14.85 psia. The pipe is 8-in. Schedule 40 commercial steel pipe, and the pump efficiency is 80%. Size a valve to control the flow of oil if the frictional pressure drop in the line is found to be 6 psi. Use a pressure drop of 10 psi across the valve and estimate the annual cost if the electricity price is $0.20/kW-hr and the pump operates 8200 hr per year. Nominal Trim size Orifice Dia. (in.) Valve size (in.) 1/4 3/8 .250 .375 ½ .500 3/4 1 .750 .812 Reduced Trim 1.5 2 3 4 6 8 10 1.250 1.625 2.625 3.500 5.000 6.250 8.000 Full Capacity Trim 3/4 1.7 3.7 6.4 11 1 1.7 3.7 6.4 11 12 1½ 1.7 3.8 6.6 12 13 25 2 1.7 3.8 6.7 13 19 26 46 31 47 110 32 49 113 195 53 126 208 400 133 224 415 640 233 442 648 1000 3 4 6 8 10 14 Figure P-5a Flow coefficient for Masoneilan’s valve Schedule 40. Separation tower P = 12.7 psia Crude tank P = 1 atm Pump 64 ft 8 ft 4 ft Figure P-5b An oil transferring system Solution -----------------------------------------------------------------------------------------$ 8,918/year 5.2 A 4-in Masoneilan valve with Cf = 0.9 and full trim has a capacity factor of 195 gpm/psi1/2 when fully opened. The pressure drop across the valve is 10 psi. (a) Calculate the flow of a liquid solution with density 0.8 g/cm3. (b) Calculate the flow of gas with average molecular weight of 35 when the valve inlet conditions are 100 psig and 100oF. (c) Calculate the flow of the gas from part (b) when the inlet pressure is 5 psig. Calculate the flow both in volumetric and in mass rate units, and compare the results for a 4-in. Fisher Controls valve (Cv = 183, Cg = 6650, C1 = 36.3). Solution (a) Calculate the flow of a liquid solution with density 0.8 g/cm3. m = (689.4 gpm)(60 min/hr)(8.330.8 lb/gal) = 275,660 lb/hr (b) Calculate the flow of gas with average molecular weight of 35 when the valve inlet conditions are 100 psig and 100oF. Qscfh = 836(195)(0.9) 114.7 (0.512) = 331,400 scfh (35 / 29)(560) The mass flow rate is determined from 35 520 (0.512) = 30,550 lb/hr m = 2.8(195)(0.9)(114.7) 29 560 (c) Calculate the flow of the gas from part (b) when the inlet pressure is 5 psig. Calculate the flow both in volumetric and in mass rate units, and compare the results for a 4-in. Fisher Controls valve (Cv = 183, Cg = 6650, C1 = 36.3). Qscfh = 836(195)(0.9) 19.7 (0.972) = 108,100 scfh (35 / 29)(560) 35 520 (0.972) = 9,965 lb/hr m = 2.8(195)(0.9)(19.7) 29 560 Using formulas from Fisher Controls we have Qscfh = 6650 59.64 10 520 (19.7) sin = 105,800 scfh (35 / 29)( 560) 36.3 19.7 rad 59.64 m = 1.06(6650) (0.115)(19.7) sin 36.3 10 = 9,761 lb/hr 19.7 rad 6. A control valve is to regulate the flow of steam into a heat exchanger with a design heat transfer rate of 10 million Btu/hr. The supply steam is saturated at 20 psig. Size the control valve for a pressure drop of 10 psi and 100% overcapacity. Assume a Masoneilan valve with Cf = 0.8. Solution -----------------------------------------------------------------------------------------From Figure 3.5-3, a 8-in. Masoneilan valve, with a coefficient of 640, is the smallest valve that can provide the service. 7. The temperature of a CSTR is controlled by an electronic (4 to 20 mA) feedback control system containing (1) a 100 to 260oF temperature transmitter, (2) a PI controller with integral time set at 2 minutes and proportional band at 25, and (3) a control valve with linear trim, airto-open action, and Cv = 10 gpm/psi0.5 through which cooling water flows. The pressure drop across the valve is a constant 25 psi. If the steady state controller output is 12 mA, how much cooling water is going through the valve? If a sudden disturbance increases reactor temperature by 10oF, what will be the immediate effect on the controller output signal and the water flow rate? Solution ------------------------------------------------------------------------------------------ (a) If the steady state controller output is 12 mA, how much cooling water is going through the valve? F = (10)(0.5) 25 = 25 gpm (b) If a sudden disturbance increases reactor temperature by 10oF, what will be the immediate effect on the controller output signal and the water flow rate? F = (10)(0.75) 25 = 37.5 gpm 8. Develop a dynamic model for the endothermic CSTR as shown in Figure 4-8. FC FT Feed Product AT Figure 4-8 Schematic of an endothermic CSTR. The process parameters and variables are given by CA: reactant concentration (initially 0.25 mol/L) CA0: feed concentration (initially 1.0 mol/L) Cp: heat capacity of the reactor feed and product (1000 cal/kgK) = Cv E/R: normalized activation energy (20,000 K) F: mass feed rate and product rate (10 kg/s) k0: rate constant (1.97×1024 s-1) Q: heat addition rate (initially 700,000 cal/s) T: reactor temperature (initially 350 K) T0: feed temperature (400 K) t: time (s) Vr: reactor volume (100 L) : the constant density of the reactor feed and product (1 kg/L) Hrxn: heat of reaction (160,000 cal/mol) These conditions represent the initial steady-state conditions. At time equal to 10 seconds, a step change in the heat addition rate is made from 700,000 cal/s to 900,000 cal/s. Plot the product stream temperature and concentration from 0 to 100 s using two separate graphs. Use Matlab to plot and label the graph with your name using the Title command. Note: The solution to this problem is in reference (4) and you should use ode23s (s for stiff) to solve the ODEs since the ODES describing the reactor are stiff differential equations. Solution Material balance for the reactant gives: Vr dC A E = Fv (CA0 CA) Vr k0 CA exp dt RT Since F = Fv dC E Vr A = F(CA0 CA)/ Vr k0CA exp dt RT Energy balance over the reactor gives: CpVr dC A E = FCp(T0 T) Vr Hrxnk0CA exp +Q dt RT