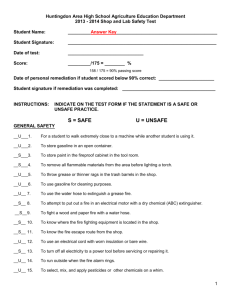

safety rules

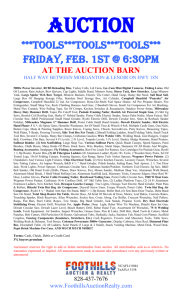

advertisement

Drill Press 1. Make all adjustments or “set-ups” with power off. 2. Select the proper bit for the material to be drilled. 3. Always wear eye protection. 4. Always remove the key from the chuck before turning on the power. 5. Be sure the speed is not too fast for larger bits. 6. Secure loose clothing or long hair. 7. Clamp all materials using a vise or clamp. 8. Always use a piece of scrap wood under the stock being drilled. Jointer 1. Always keep the safety guard in place. 2. Keep hands at least 6” away from moving parts. 3. Be sure the fence is adjusted and locked in tight. 4. Keep stock firmly against the fence and table. 5. Maximum cut is 1/8”. 6. Minimum length of stock is 12”. 7. Always use eye protection. Surfacer (Planer) 1. Never look into machine when power is on. 2. Stand to one side of the machine when operating. 3. Check wood for nails, loose knots, and other defects. 4. The stock should be at least 17” long and ¼” thick. 5. Do not make cuts over 1/16” deep. 6. Never adjust machine while running. 7. Always wear eye protection. Portable Belt Sander 1. Always wear safety glasses. 2. Always show the instructor your set up. 3. Loose clothing or long hair must be tied back. 4. Always clamp work piece to table or in a vise. 5. Always unplug The sander before changing the belt. 6. Always lay the sander on its side when finished. 7. Always check the tracking and tension before using. 8. Always check to make sure the trigger lock is off. 9. Never start the sander on the work piece. Palm Sander 1. Always wear safety glasses. 2. Always show the instructor your set up. 3. Never place the sander down while moving. 4. Always unplug the sander before changing the paper. 5. Always clamp work piece to table, in a vise or use the sanding pad. Portable Electric Drill 1. Always wear safety glasses. 2. Always show the instructors your set up. 3. Always clamp work piece to the table or in a vise. 4. Never force the drill. 5. Never move the drill from side to side. 6. If drill does not have a keyless chuck unplug drill before changing bit and remove chuck key. 7. Only use the proper bits. Router 1. Always wear safety glasses. 2. Always show the instructors your set up. 3. Blade must be securely mounted in the chuck to a depth of at least ½” 4. Securely clamp work. 5. Start the machine with the bit away from the work piece. 6. Hold the router with both hands firmly. 7. Feed the router smoothly through the cut from left to right. 8. Keep the base flat on the work piece. 9. After cutting is complete allow the bit to come to a stop before picking up the router. 10. Always unplug the router to change the bit or make adjustments. Scroll Saw 1. Make sure blade teeth face down. 2. Make sure blade is fastened securely to the upper and lower chuck. 3. Adjust guide so it applies slight pressure on the material. 4. Secure material with both hands while cutting. 5. Keep fingers outside the plane of the blade. 6. Always wear eye protection. Table Saw 1. Keep safety guard in place. 2. Make all adjustments with the power off. 3. Set the saw blade to no more than ¼” above stock. 4. Use a 6” margin of safety. 5. Freehand cutting is not permitted. 6. Miter gauge and fence are not used simultaneously. 7. Use a push stick for final 6” of cut. 8. Never stand in line with the saw blade. 9. Always use eye protection. Belt Sander & Disc Sander 1. Keep hands away from abrasive surface. 2. Make sure disc or belt is secure. 3. Always secure material against table, stop fence, or miter gage. 4. Always use eye protection. 5. Use the “down-side” of the abrasive surface. 6. Always keep materials moving against abrasive surface. Band Saw 1. Use a 4” margin of safety. 2. Keep upper guide within ¼” of material. 3. Saw curves gradually using relief cuts. 4. If the blade breaks, turn off the machine and inform instructor. 5. Avoid backing out of cuts with the power on. 6. Do not cut cylindrical stock without a clamp. 7. Remove scrap only when the blade has stopped. 8. Always wear eye protection.