Second order conductors Electrolysis with Cobra4

TEP

Related Topics

Electrolysis, Electrode polarisation, Conductivity, Ohm’s law

Principle

With the function generator module current/voltage curves are recorded while electrolysing a copper (II)

sulphate solution. Copper wire and graphite are used as electrode materials. The resistance of the electrolysis cell is dependant on the chemical reactions taking place at different characteristic voltages and

on ion mobility.

Material

1 Cobra4 Wireless Manager

12600-00

1 Cobra4 Wireless-Link

12601-00

Cobra4 Sensor-Unit Electricity, Current ±6

1

12644-00

A/Voltage ±30

Digital Function Generator, USB, incl. Cob1

13654-99

ra4 Software

1 Tripod base PHYWE

02002-55

1 Support rod PHYWE, square, l = 400 mm 02026-55

1 Right angle clamp PHYWE

02040-55

1 Holder for 2 Electrodes

45284-01

Graphite electrodes, d = 5 mm,

1

44510-00

l = 150 mm, 6 pcs.

1 Copper wire, d = 0.5 mm, l = 50 m

06106-03

1 Glass beaker Duran, short, 150 ml

36012-00

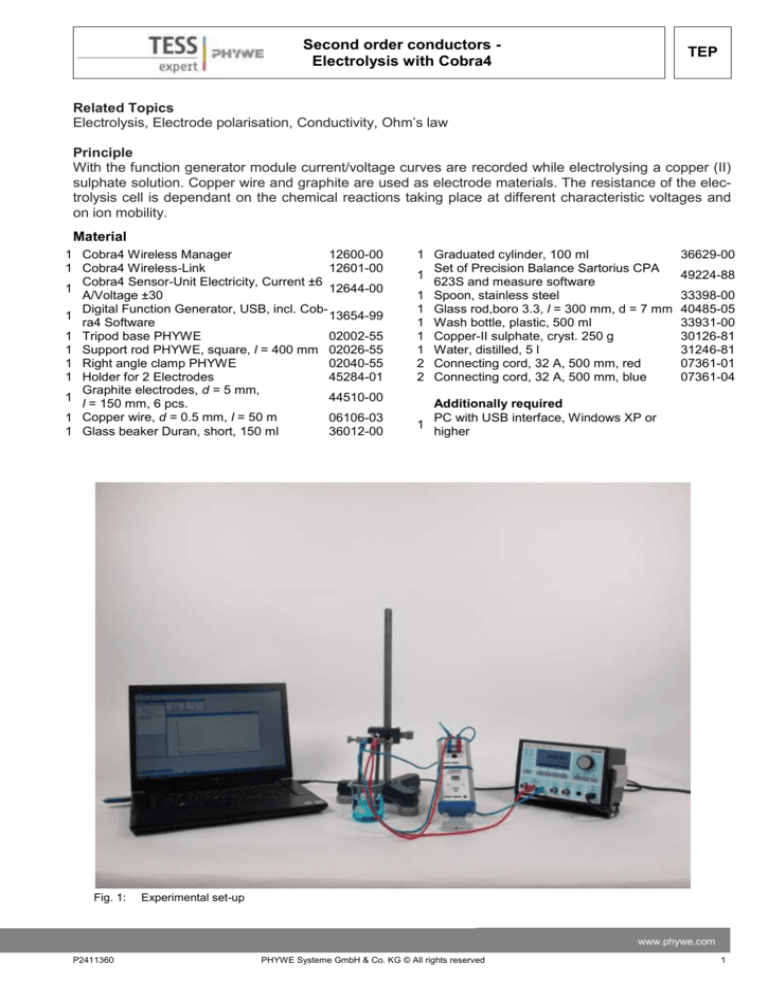

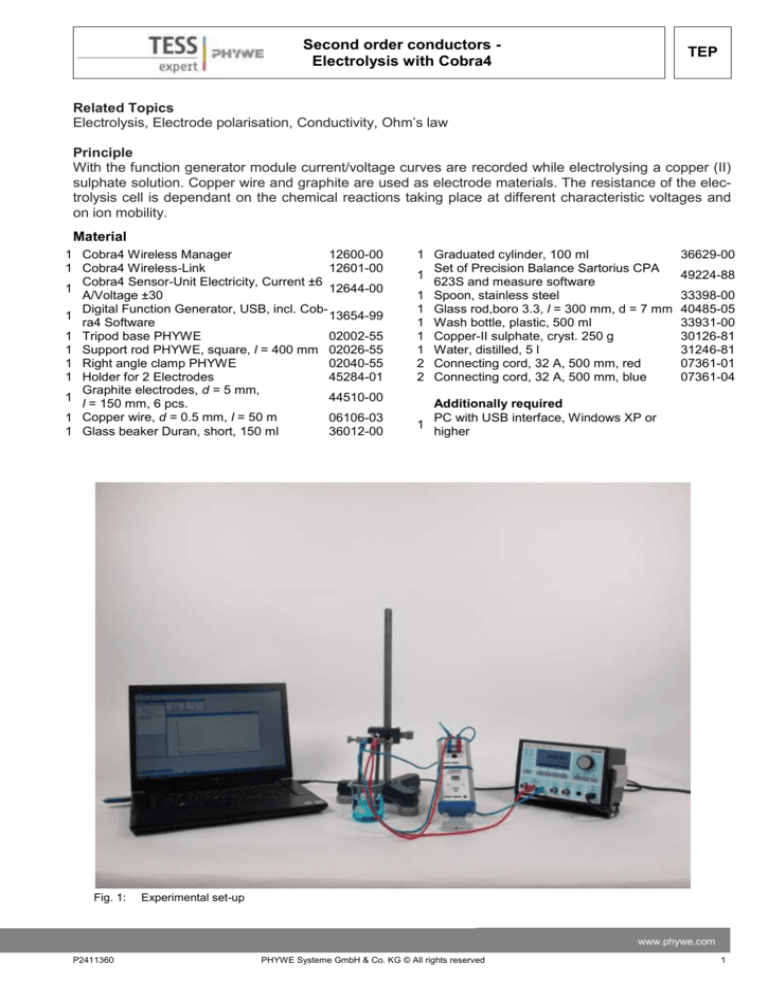

Fig. 1:

1 Graduated cylinder, 100 ml

Set of Precision Balance Sartorius CPA

1

623S and measure software

1 Spoon, stainless steel

1 Glass rod,boro 3.3, l = 300 mm, d = 7 mm

1 Wash bottle, plastic, 500 ml

1 Copper-II sulphate, cryst. 250 g

1 Water, distilled, 5 l

2 Connecting cord, 32 A, 500 mm, red

2 Connecting cord, 32 A, 500 mm, blue

36629-00

49224-88

33398-00

40485-05

33931-00

30126-81

31246-81

07361-01

07361-04

Additionally required

PC with USB interface, Windows XP or

1

higher

Experimental set-up

www.phywe.com

P2411360

PHYWE Systeme GmbH & Co. KG © All rights reserved

1

TEP

Second order conductors Electrolysis with Cobra4

Safety instructions

When handling chemicals, you should wear suitable protective gloves, safety goggles, and suitable

clothing. Please refer to the appendix for detailed safety instructions.

Tasks

Measure the correlation between voltage and current on second order conductors (copper (II) sulphate

solution) using two different materials - graphite electrodes and copper wires.

Set-up and procedure

Prepare a 0.1 M copper sulphate solution by dissolving 2.50 g of copper (II) sulphate in 100 ml of

distilled water in the 150 ml glass beaker. Mind the

safety instructions for copper (II) sulphate!

Connect the Cobra4 Wireless Manager to a USB

port of the computer, plug the Cobra4 SensorElectricity on the Cobra4 Wireless-Link and connect the Digital Function Generator to another

USB port.

Set up the equipment according to Fig. 1. Begin

with copper wire electrodes – straight pieces of

copper wire of same length as the graphite electrodes put into the electrode holders. Start the

“measure” program on your computer and load the

“Second order conductors” experiment. (Experiment > Open experiment). All pre-settings that are

necessary for measured value recording are now

carried out.

The surface in contact with the solution determines

the resistance of the electrolysis cell. The surface

should be not too big, as not to exeed the maximum current of 200 mA of the function generator

at maximum voltage of 10 V, but not too small, as

not to have much current noise in the measurement. Use the „U2“ values to check function genFig.2: Digital Function Generator settings.

erator linearity.Click on

in the icon strip to start

measurement.You can lower the measurement

speed with the delay setting or by recording with a lower step size (Fig. 2). Too fast recording will distort

the curves since the reactions and ion diffusion take time and plateaus in the characteristic curves may

not be visible. If you measure two curves right one after the other, the second curve will differ a lot from

the first one – waiting or stirring will restore the old conditions. If you have a close look on the positive

electrode – the anode – , you can see after a measurement a region of higher optical density (of higher

copper ion concentration) in the water stay for quite a while until it dissolves – and you can see liquid of

higher optical density flow from the anode during electrolysis. The positive wire gets visibly etched and

on the negative wire a black “sponge“ of elementary copper is deposited. Gas bubbles form on the anode from 1.2 V on and on the cathode from 4.5 V on. The current rises linearly from zero volt on and

reaches a plateau. From 1.2 V on it begins to rise again – running into a linear part afterwards. From 4.5

2

PHYWE Systeme GmbH & Co. KG © All rights reserved

P2411360

Second order conductors Electrolysis with Cobra4

TEP

V on the slope gets steeper – or depending on the conditions, a plateau may form below 4.5 V. At some

voltage above 8 V the current may break down again.

Now remove the copper wires and put the carbon electrodes into the holder. Immerse the electrodes

about 2 cm into the solution. Start the measurement again. Nearly no current flows up to 1.2 V. Then the

current rises, reaches a linear part and forms a plateau. Bubbles form on the anode and copper is deposited as black microcrystals on the cathode. Above 4.5 V the current rises again and bubbles form on

both electrodes.

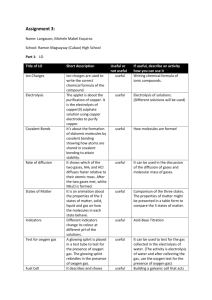

The obtained data may look like Fig. 3. The curves may be put into one diagram with the “Measurement“

> “Assume channel“ function. You may also try to electrolyse other salt solutions – like common salt (sodium chloride) or natron (sodium hydrogen carbonate) ect. or check the cleanliness of your distilled water by trying to electrolyse it.

Fig.. 3:

Sample measurements.

Theory and evaluation

In the case of second order conductors Ohm’s law does not apply. The mechanism of charge transport,

i.e. ion diffusion, is not only dependant on applied voltage but also on various chemical reactions taking

Cathode: Cu2+ + 2 e- Cu (1)

Anode: Cu Cu2+ + 2 e- (2)

As many copper ions go into solution at the anode as are deposited at the cathode and the concentration

of copper ions in the solution altogether is not changed. This process is in large scale industrial use for

copper refining. But since ion transport is not fast, a plateau in current may occur with increasing voltage

depending on initial copper (II) sulphate concentration and electrode geometry when the current is as

high as the possible ion transport – i.e. all availible copper ions around the cathode get deposited and

current is limited by the rate in which copper ions diffuse to the cathode or else, as in this case of Fig. 6,

the maximum rate of ions going into solution at the anode is reached as the copper concentration around

the anode reaches saturation. Above the deposition potential of oxygen of 1.2 V another reaction is possible too and lets the current increase again:

Anode: 6 H2O O2 + 4 H3O+ + 4 e- (3)

www.phywe.com

P2411360

PHYWE Systeme GmbH & Co. KG © All rights reserved

3

Second order conductors Electrolysis with Cobra4

TEP

i.e. oxygen and sulphuric acid is formed at the anode in addition to processes (1) and (2). Above 4.5 V

hydrogen can be formed at the cathode resulting in an current increase again:

Cathode: 2 H2O + 2 e- H2 + 2 OH- (4)

It depends on the conditions that limit the other processes whether a plateau forms in the current characteristic or the slope of the current curve just gets steeper with a new possible process. In case of Fig. 6

the copper ions get depleted at 8.8 V which results in current decrease. When electrolysing the copper

(II) sulphate solution with carbon electrodes, process (2) is impossible due to lack of copper, so no current flows until 1.2 V is reached and processes (1) and (3) allow current flow - as the sum of electrons

coming out of the cathode has to equal the sum of electrons entering the anode in any case. Above 4.5

V the processes (1), (3) and Fig.6 additionally (4) are possible resulting in current increase.

Appendix

Hazard symbol, signal word

Hazard statements

Precautionary statements

H319 Causes serious eye

irritation.

H315 Causes skin irritation.

H302 Harmful if swallowed.

H410 Very toxic to aquatic

life with long lasting effects.

P273 Avoid release to

the environment.

P302 + P352 IF ON

SKIN: Wash with plenty

of soap and water.

P305 + P351 + P338 IF

IN EYES: Rinse cautiously with water for

several minutes. Remove

contact lenses, if present

and easy to do. Continue

rinsing.

P501 Dispose of contents/container to an approved waste disposal

plant.

Copper(II) sulphate pentahydrate

4

PHYWE Systeme GmbH & Co. KG © All rights reserved

P2411360