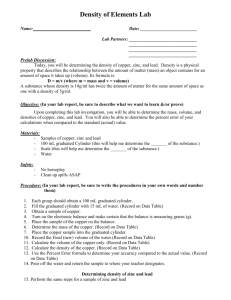

copper stuff

advertisement

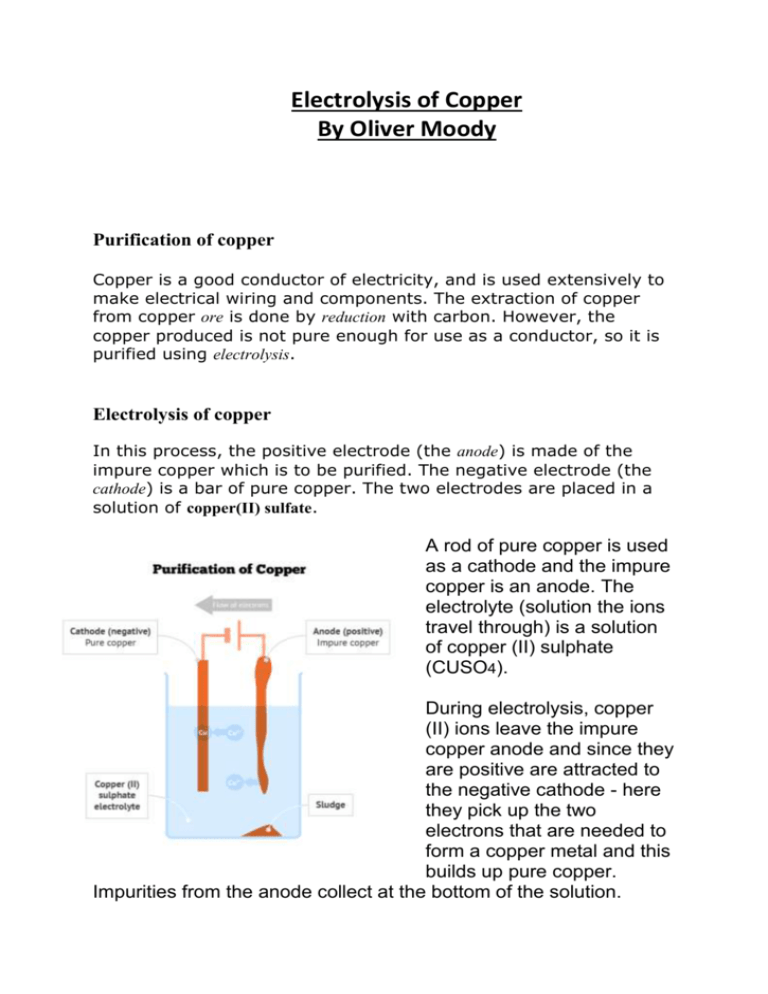

Electrolysis of Copper By Oliver Moody Purification of copper Copper is a good conductor of electricity, and is used extensively to make electrical wiring and components. The extraction of copper from copper ore is done by reduction with carbon. However, the copper produced is not pure enough for use as a conductor, so it is purified using electrolysis. Electrolysis of copper In this process, the positive electrode (the anode) is made of the impure copper which is to be purified. The negative electrode (the cathode) is a bar of pure copper. The two electrodes are placed in a solution of copper(II) sulfate. A rod of pure copper is used as a cathode and the impure copper is an anode. The electrolyte (solution the ions travel through) is a solution of copper (II) sulphate (CUSO4). During electrolysis, copper (II) ions leave the impure copper anode and since they are positive are attracted to the negative cathode - here they pick up the two electrons that are needed to form a copper metal and this builds up pure copper. Impurities from the anode collect at the bottom of the solution. Anode sludge The impurities found in copper anodes as well as the structure and manner of dissolving of anodes, continuously cause. small quantities of particulates and impurities to be generated. These go into the plating bath. The black phosphorus.film which forms on phosphatized anodes in copper sulphate baths winds up in the plating solution as the anodes,.corrode and get smaller in the normal plating process. Normal filtration practice removes these particulates and precipitates without problem. This so called "sludge" formation is normal and expected.