Specification for tender lot 1 EPMA

advertisement

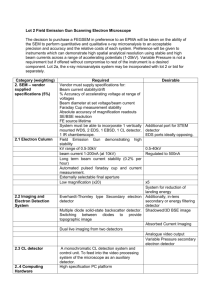

Specification –EPMA/SEM Background An electron microprobe (EPMA) OR scanning electron microscope (SEM) capable of delivering high precision quantitative chemical x-ray analysis of sub-micron areas is required for the pursuance of a research project to study diffusion mechanisms in minerals. We require analyses of elements with detection limits of down to about 50 parts per million at highest achievable spatial resolution. We envisage the microscope will thus incorporate both wavelength and energy dispersive detectors. We are tendering for two instruments with the most likely outcome being that only one lot will be purchased. Lot 1 is specifically a multi wavelength dispersive spectrometer EPMA and lot 2 a Field Emission sourced Scanning electron microscope. A subset of lot 2 will be the additional provision of energy and wavelength dispersive spectrometers. The instrument will form one of a suite of three laboratories to compliment existing tungsten sourced EPMA and SEM in the long established electron microbeam laboratory of the dept of Earth Sciences under the management of Dr Stuart Kearns. Specification – Lot 1 EPMA Category (weighting) Required Desirable 1. EPMA – Vendor Vendor must supply specifications for: supplied performance Beam current stability/drift specifications (5%) % Accuracy of accelerating voltage at range of voltages Beam diameter at set voltage/beam current Faraday Cup measurement stability Absolute accuracy of magnification readouts SE/BSE resolution FE source lifetime WD and ED resolution and performance 1.1 WD Analysis 5 vertically mounted Wavelength dispersive spectrometers Combination of appropriate Gas Flow and/or sealed proportional counters including necessary gas regulators. In total 4 PETs, 3 TAPs and 3 LIFs 1.2 ED Analysis Integrated EDS – SDD-type detector (128eV at MnKa resolution) Ultra thin window for boron xray. Capable of Spectral Imaging (storage of spectrum for every pixel on x-ray map) At least three specs to have ‘high count-rate’ set-up (large crystals and/or small Rowland circle) At least one spectrometer to have slits option. Either high and low pressure counters or xenon counters. 1 spectrometer to have capacity for analysis of B,C,N and O. 125eV resolution or better. 1.3 Electron Column 1.4 Electron Imaging System 1.5 Vacuum System 1.6 Computing (5%) Software Control Package 1.7 Optical microscope 1.8 Specimen Chamber, Stage, (5%) Stage Control Sample Holders 1.9 Documentation (5%) High Resolution source electron gun (not tungsten) kV range of 1-30kV Regulated beam current 1-200nA Long term beam current stability Automated pulsed faraday cup Externally selectable final aperture Capable of taking a EDS spectrometer supplied by a third party vendor with detailed mechanical drawings of the EDS mounting system, aperture and port configuration. Everhardt-Thornley type Secondary electron detector Multiple diode solid-state backscatter detector Fully automated vacuum system. Sufficient length to extend rotary pumps into adjacent room (5m) High specification PC platform Minimum of two dedicated screens for software package and a third screen for EDS Separate monitor for electron image viewing Separate monitor for optical image viewing Complete software system to perform quantitative and qualitative x-ray microanalysis and image acquisition (from all detectors) and processing options. To include Thin film analysis routines. It is a requirement that the software can acquire both ED and WD simultaneously and integrated for combined analysis. It is a further requirement that an element can be analysed by summing the signal from more than one spectrometer for both quant and x-ray mapping. 2 licences of the software to be supplied Free upgrades to latest version for 10 years including change to new operating systems. Light microscope with zoom optics and autofocus capability Digital Image store of optical image. Large specimen chamber. Versatile 50x80mm movement in X and Y with preferably 5mm movement in Z. Airlock exchange of specimens. High precision X,Y and Z stage movement with dedicated trackball/joystick to move in X and Y. Minimum of 4 sample holders and shuttles where required to take range of specimen mounts including 6x25mm diameter, and 3x thin sections (48x28mm). All mechanical and electrical drawings to be included. All manuals for third party items supplied by the vendor (e.g. vacuum products). List of all spare parts and catalogue/order information. FEG source 1-40kV Regulated to 500nA 3 licences Transmitted light option 100x100mm X,Y movement 0.5 micron reproducibility in X, Y and Z.. All documentation to be in English Paper copy of all instruction manuals List of specialised tools required for maintenance 1.10 Support and Warranty (10%) Training 1.11 Demonstration (50%) 1.12 Pricing and delivery (20%) 1.13 Final Acceptance 1.14 Options Warranty to last 12 months after final acceptance. Four years full service cover to follow 12 month warranty period. On-site training required for lab manager. Assumed to be 6 days. See below All components must be operational before final acceptance – no exceptions. Upon repeat analysis of demonstration tests on same samples to the approval of lab manager to be undertaken after all specification checks have been performed. To be listed and priced separately 1- UPS system 3- Panchromatic cathodoluminescence detector Demonstration required will evaluate those components not weighted above. Proportional weightings in brackets: 1) (10%) WDS qualitative scans on sample of Monazite (20kV, 20nA 5micron spot, to take 1 hour) a) PET across range of U-Th on both gas flow counters (at more than one pressure where applicable and xenon counters) b) LIF in range Ce-Gd L lines c) PET in range La-Nd (if possible) 2) (10%) WDS qualitative scans on Apatite across Fluorine peak using both integral and differential PHA modes on TAP and 60Angstrom spaced crystal (e.g. PC0) at 15kV, 10nA, 10micron spot, to take 30mins) 3) (20)X-ray image of orthopyroxene acquired at highest possible spatial resolution using 10kV, 200nA beam for Al, Mg, Fe, Ca, Na on WDS and simultaneous acquire full spectrum image on EDS. Image to be quantified (i.e with background correction and ZAF processed). Slow scan image to run for several hours overnight. 4) (10%) Line profiles across orthopyroxene (same elements and conditions as above). Maximum resolution across a 50micron line using both stage and beam move to take 30mins each. 5) (10%) High resolution SE image (1, 5 and 25kV) – gold coated foram 6) (10%) BSE image to demonstrate high Z contrast – using oscillatory carbon coated zoned mineral 7) (30%) Quantitative analysis of 3 mineral specimens – monazite, kaersutite, olivine. Repeat of 10 analyses on each at 10kV and 20kV.Quantitative analysis of small silicate and oxide crystals in experimental charge. All analyses will be benchmarked against analysis at UoB on Cameca SX100 #837 under same operating conditions. Estimated 2 days of analysis including overnight. All samples and primary calibration standards to be supplied by UoB.