OD 660nm . Calculate growth rate (µ) and generation - NO

advertisement

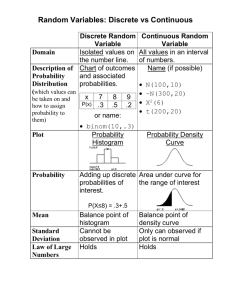

TBT4140 Biochemical Engineering NTNU, Fall 2012 Laboratory exercise Group: Ingrid Andreassen – ingran@stud.ntnu.no Ove Øyås – oyas@stud.ntnu.no Martin Borud – martbor@stud.ntnu.no 1 Contents 1. Plot growth curve (semi-log) OD660nm. Calculate growth rate (µ) and generation time (g). ......................................................................................................................................................................... 3 2. Plot OD660 nm versus cell concentration (g/mL). What is the relation between OD and dry weight (DW)? (DW/OD). ...................................................................................................................... 3 3. Plot O2 and CO2 as a function of time. Explain the graphs. Does it fit with what you observe in the growth curve? ..................................................................................................................... 6 4. Show calculation of limiting component in medium. Which two assumptions must be met for these calculations to be correct? ............................................................................................... 7 5. Calculate OUR [mmol/(L-hr)] using mass balance ........................................................................ 9 6. Calculate OUR [mmol/(L-hr) and kla [s-1] using dynamic method of gassing out. Which assumptions are made when calculating kla and OUR? .................................................. 11 7. Do OUR values from dynamic method and mass balance match? If not, why?................ 14 8. Calculate yield on carbon source (one time: end of the experiment) and yield on oxygen (x times: when you have OUR) ................................................................................................ 14 9. Calculation of the respiratory quotient (RQ) ................................................................................ 15 10. Calculate specific enzyme activity given as (µmol ONPG hydrolysed)/(min x g). ....... 16 2 1. Plot growth curve (semi-log) OD660nm. Calculate growth rate (µ) and generation time (g). OD (660 nm) [-] 100 10 1 0.1 0 1 2 3 4 5 6 7 8 Time from start [h] Figure 1.1: Growth curve for Escherichia coli grown at 37 °C. OD660 nm plotted against time. Growth rate: m= ln(OD2 ) - ln(OD1 ) 10,28 - 2,62 1 = = 3,83 t 2 - t1 (5,5 - 3,5)h h Generation time: g= ln 2 m = ln 2 = 0,18h 1 3, 83 h 2. Plot OD660 nm versus cell concentration (g/mL). What is the relation between OD and dry weight (DW)? (DW/OD). Data used for plotting OD660 nm versus cell concentration and dry weight is given in Table 2.1. 3 Table 2.1: Values for OD 660 nm dry weight and cell concentration. Dry weight [g] OD660 nm Cell concetration [g/ml] 0.2075 1.28 0.02075 0.2085 2.62 0.02085 0.2493 16.8 0.02493 Presuming that the relationship between OD and cell concentration is linear in the observed range and exploiting the fact that cell concentration is known to be 0.02085 g/mL when OD660 nm is 2.62, the following formula was utilized for calculating cell concentrations from OD measaurements: Cell concentration = 𝑂𝐷660 𝑛𝑚 ∙ 0.02085 g/mL 2.62 A plot of OD660 nm versus cell concentration is shown in Figure 2.1. The data used to create the plot are given in Table 2.2. Table 2.2: Data for OD660 nm and cell concentration. OD660 nm Cell concentration [g/mL] 0.214 0.00171 0.248 0.00198 0.373 0.00297 0.516 0.00411 0.992 0.00790 1.288 0.01027 1.775 0.01415 2.616 0.02085 3.950 0.03149 5.560 0.04431 6.700 0.05340 10.28 0.08193 13.40 0.10680 15.60 0.12433 4 18.90 0.15064 16.80 0.13390 0.16 0.14 y = 0,008x + 2E-17 OD (660 nm) 0.12 0.1 0.08 0.06 0.04 0.02 0 0 5 10 Cell concentration [g/mL] 15 20 Figure 2.1: Plot of OD660 nm versus cell concentration. A fitted curve found by linear regression is included and its equation is shown. Data from Table 2.1 was used to produce a plot of dry weight against OD660 nm. This is shown in Figure 2.2. 0.26 0.25 Dryweight [g] y = 0.0028x + 0.2027 0.24 0.23 0.22 0.21 0.2 0 5 10 OD (660 nm) 15 20 Figure 2.2: Plot of OD660 nm versus cell dry weight. A fitted curve found by linear regression is included and its equation is shown. 5 The slope of the trendline in Figure 2.2 gives the relationship between dry weight and OD. The slope is determined to 0.0028 g and therefore 𝐷𝑊 = 0.0028 g 𝑂𝐷 3. Plot O2 and CO2 as a function of time. Explain the graphs. Does it fit with what you observe in the growth curve? Figure 3.1 shows the flow of oxygen and carbon dioxide as a function of time. 25 10 9 20 8 15 6 5 10 4 Flow CO2 [L/min] Flow O2 [L/min] 7 CO2 O2 3 5 2 1 0 0 0 100 200 300 Time [min] 400 500 Figure 3.1: Flow of O2 and CO2 as a function of time. As can be seen from the graphs in Figure 3.1, the fraction of oxygen in the outlet air decreases during the first 5-6 hours of the experiment. The fraction of carbon dioxide increases in this period. Moreover, the rate of change in the levels of both gases seems to increase with time; O2 decreases and CO2 increases seemingly exponentially with time. 6 As can be seen from Figure 1.1, the time period during which this is observed corresponds to the growth phase of the bacteria in the culture. In this period, the cells are consuming oxygen for growth and producing carbon dioxide. As the cell concentration increases, so does the amount of oxygen needed for doubling as well as the amount of carbon dioxide produced, explaining the observed gas flows. After 5-6 hours, the O2 and CO2 levels increase and decrease, respectively, fairly abruptly. This should be an indicator that the cells have stopped growing. After a while, the oxygen flow decreases and the carbon dioxide flow increases again, signaling that growth has resumed. After a short while however, the oxygen level begins to rise along with the flow of carbon dioxide, before the CO2 flow abruptly decreases again. This particular observation is difficult to explain based on the growth of the bacteria in the culture. A stabilization in the gas levels due to the bacteria entering the stationary phase would be expected. 4. Show calculation of limiting component in medium. Which two assumptions must be met for these calculations to be correct? Data for cell composition as well as molecular weight for the components of the cell are given in Table 4.1. Table 4.2 shows the concentration, mass, molecular mass and number of moles of the components in the medium. Table 4.1: The composition of the cell and the molecular weights of the elements. Component Composition of E. Coli (% dry weight) Molecular weight [g/mol] Glucose 53 180 N 12 14 S 1 32.1 P 3 31 Mg 0.5 24.3 Ca 0.5 40.1 K 1 39.1 Na 1 23 Cl 0.5 35.5 Fe 0.2 55.5 7 Table 4.1:The concentration, mass, molecular mass and number of moles of the components in the medium. Concentration [g/L] m [g] M [g/mol] n [mol] NH4Cl 8 4 53.5 0.074766355 Yeast extract 2 1 - - KH2PO4 1 0,5 136.1 0.003673769 Na2HPO4·2H2O 6 3 178.05 0,0168492 CaCl2·2H2O 0.01 0.005 147.02 3.4009E-05 Na2SO4 1 0.5 142.06 0.00351964 FeSO4·7H2O 0.03 0.0081 278.05 2.91315E-05 Lactose 6 1.62 - - Glucose 20 5.4 - - MgSO4·7H2O 0.02 0.0054 246.51 2.19058E-05 B-medium A-medium Component Table 4.3 shows the amount of the different elements in the medium, the weight percentages of the different elements compared to the total weight of the elements and the difference between the weight percentage and the composition of elements in E. coli. Table 4.2: The amount of the different elements in the medium, the weight percentages of the different elements compared to the total weight of the elements and the difference between the weight percentage and the composition of elements in E. coli (see Table 3.1). Element n[mol] m[g] Weight % Difference Nitrogen 0.0748 1.0467 36.3020 24.3020 Sulfur 0.0035 0.1139 3.9507 2.9507 Phospate 0.0205 0.6362 22.0647 19.0647 Magnesium 0.0000 0.0005 0.0185 -0.4815 Calcium 0.0000 0.0014 0.0473 -0.4527 Potassium 0.0037 0.1436 4.9818 3.9818 Sodium 0.0407 0.9370 32.4953 31.4953 Chloride 0.0001 0.0024 0.0837 -0.4163 Iron 0.0000 0.0016 0.0561 -0.1439 8 As can be seen from Table 3.3, magnesium shows the largest deviation from the expected amount needed based on the composition of the cell. Magnesium is therefore the limiting component. For these calculations to be correct we must assume that there are no side reactions, the that the given cell composition is correct and that all the elements are continually consumed in equal amounts. Also, we should assume that 1 mol of lactose yields 1 mol of glucose. 5. Calculate OUR [mmol/(L-hr)] using mass balance Our is calculated from the following equation OUR = F ( xin xout ) V where F is the flow, V is the volume, xin is the oxygen ratio into the fermenter and xout is the oxygen ratio out. The preferred unit for flow is mmol/h. To convert the unit of the measured value, L/h, into mmol/h, ideal gas law is assumed and the following formula employed: V p t F 1000 mmol/h R T The resulting flow is F 0.4 1.049 1000 1.65 mmol/h 0.082 310 Data used in the calculation of OUR is shown in Table 5.1. A plot of OUR against time is shown in Figure 5.1. 9 Table 5.1: Measured and calculated data needed to calculate OUR. Time from start [h] Weight [g] O2, out (%) Volume [L] OUR [mmol/L·h] 0 10356.6 20.6 0.7900 0.00731 0.5 10343.6 20.38 0.7887 0.01192 1 10343.6 20.19 0.7887 0.01590 1.5 10326.3 20.08 0.7871 0.01824 2 10323.2 19.53 0.7868 0.02978 2.5 10304.4 18.29 0.7850 0.05591 3 10305.2 18.69 0.7850 0.04750 3.5 10277.2 18.29 0.7823 0.05610 4 10290.4 17.18 0.7836 0.07938 0.09 0.08 OUR [mmol/L·h] 0.07 0.06 0.05 0.04 0.03 0.02 0.01 0.00 0 1 2 3 Time [h] Figure 5.1: Plot of OUR against time. 10 4 5 6. Calculate OUR [mmol/(L-hr) and kla [s-1] using dynamic method of gassing out. Which assumptions are made when calculating kla and OUR? To calculate kla, the dynamic method of gassing out was used. DO was recorded over time after turning off the air flow into the fermenter. At a DO of 5%, the air flow was turned back on and DO recorded until a stable value was reached. The values obtained from the first gassing out are shown in Figure 6.1. 60 DO (% of maximum) [-] 50 40 30 y = -0.4306x + 39.227 R² = 0.9694 20 10 0 0 50 100 150 200 250 Time [s] 300 350 400 450 Figure 6.1: DO plotted against time for the first gassing out. A trendline found by regression is added to the initial, linear part of the curve. The equation of the trendline and its coefficient of determination, R2, are also shown. OUR was calculated from the slope of a trendline found by performing linear regression on the initial, linear part of the curve shown in Figure 6.1. The negative value of this slope gives OUR with units s-1. To determine OUR with the desired units mmol/L·h, the following formula was used: 𝑂𝑈𝑅 [ mmol 𝑂𝑈𝑅 [s−1 ] 1 ]= ∙ 3600 s/h ∙ 𝐶𝐿,𝑚𝑎𝑥 · L∙h 100 𝑀𝑊 CL,max is given by the following empirical equation: CL,max 14.161 (0.3943 T ) (0.007714 (T 2 )) (0.0000646 (T 3 )) 6,86 mg/L using T = 37 °C. From this, OUR was determined to be 6.65 mmol/L·h. The kla value can be found using the following equation 11 kla (t2 t1 ) ln( CL ' CL1 ) CL ' CL 2 where CL1 is the CL value at t1 and CL2 at t2. CL’ was found to be 52%. From this equation it can be seen that a plot of ln(𝐶𝐿′ − 𝐶𝐿1 )/(𝐶𝐿′ − 𝐶𝐿2 ) against time should result in a linear plot with kla as slope. A plot of ln(𝐶𝐿′ − 𝐶𝐿1 )/(𝐶𝐿′ − 𝐶𝐿2 ) against time for the first gassing out is shown in Figure 6.2. 0.8 ln(CL'-CL1)/(CL'-CL2) 0.7 0.6 0.5 y = 0.0038x R² = 0.9661 0.4 0.3 0.2 0.1 0 0 20 40 60 80 Time [s] 100 120 140 160 Figure 6.2: Plot of 𝐥𝐧(𝑪′𝑳 − 𝑪𝑳𝟏 )/(𝑪′𝑳 − 𝑪𝑳𝟐 ) against time for the first gassing out. A trendline found by linear regression is included and the equation of the trendline as well as its coefficient of determination, R2, are shown. The slope of the trendline in Figure 6.2 gives kla = 0.0038 s-1 for the first gassing out. The values obtained from the second gassing out are shown in Figure 6.3. 12 35 Do (% of maximum) [-9 30 25 y = -0.6425x + 39.133 R² = 0.9837 20 15 10 5 0 0 50 100 150 200 250 Time [s] Figure 6.3: DO plotted against time for the second gassing out. A trendline found by regression is added to the initial, linear part of the curve. The equation of the trendline and its coefficient of determination, R2, are also shown. For the second gassing out, OUR was determined to 9.92 mmol/L·h. A plot of ln(𝐶𝐿′ − 𝐶𝐿1 )/(𝐶𝐿′ − 𝐶𝐿2 ) against time for the second gassing out is shown in Figure 6.4. 0.9 ln(CL'-CL1)/(CL'-CL2) 0.8 0.7 0.6 0.5 0.4 0.3 y = 0.0085x R² = 0.9837 0.2 0.1 0 0 20 40 60 80 Time [s] 100 120 140 160 Figure 6.4: Plot of 𝐥𝐧(𝑪′𝑳 − 𝑪𝑳𝟏 )/(𝑪′𝑳 − 𝑪𝑳𝟐 ) against time for the second gassing out. A trendline found by linear regression is included and the equation of the trendline as well as its coefficient of determination, R2, are shown. The slope of the trendline in Figure 6.4 gives kla = 0.0085 s-1 for the second gassing out. 13 The following assumptions were made in the calculations: 1. The liquid phase is well mixed 2. The response time of the dissolved oxygen electrode is much smaller than (1/kla) 3. The measurement is performed at sufficiently high stirrer speed to eliminate liquid boundary layers at the surface of the oxygen probe 4. Gas-phase dynamics can be ignored 7. Do OUR values from dynamic method and mass balance match? If not, why? No, the OUR values determined by the dynamic method of gassing out do not match those obtained from the mass balance (see Table 5.1 and Figure 5.1). The difference between the values is very big, about a factor of 100. It is not known precisely what causes this deviation. One or more of the assumptions made in the calculations in section may not be valid or the empirical formula used to calculate CL,max may be very inaccurate at 37 °C (it is determined for 36 °C). the assumption of ideal gas in section 5 could also be invalid. It does however seem unlikely that any of these errors should result in a difference of the magnitude that is actually observed. It seems probable that an invalidity in the mass balances is responsible for the deviation, as significant gas and liquid leakages did occur several times during the experiment. It is plausible that the loss of mass from these leakages has made the mass balance calculations invalid. 8. Calculate yield on carbon source (one time: end of the experiment) and yield on oxygen (x times: when you have OUR) To calculate the yield on carbon source, we must know the total mass of the cells in the reactor. Therefore, the relation between OD and dry weight used in section 2 is used. At the end of the experiment, the OD is … which gives a cell concentration of … . Assuming that the reactor volume is constant – a necessary but probably highly incorrect assumption – the bacterial biomass at the end of the experiment would be. Given the initial concentrations of glucose and lactose in the medium, it is known that 20.8 g of carbon sources were used. The yield on carbon source can thus be calculated as follows: 𝑌𝑐𝑎𝑟𝑏𝑜𝑛 = g 𝑐𝑒𝑙𝑙𝑠,𝑒𝑛𝑑 = g 𝑔𝑙𝑢𝑐𝑜𝑠𝑒 + g 𝑙𝑎𝑐𝑡𝑜𝑠𝑒 = g cells g carbon The yield on oxygen can be calculated from 14 𝑌𝑂2 = µ 𝑂𝑈𝑅 9. Calculation of the respiratory quotient (RQ) 15 16 10. Calculate specific enzyme activity given as (µmol ONPG hydrolysed)/(min x g). Change in absorbance at 420 nm as a result of ONPG hydrolysis by β-galactosidase was measured over time for each of three samples taken during the experiment. Data obtained from these measurements are given in Table 10.1, 10.2 and 10.3 and plots of these data are shown in Figure 10.1, 10.2 and 10.3. Table 10.1: Measured absorbance at 420 nm with time for samples 1, 2 and 3. Absorbance (420 nm) Time [s] Sample 1 Sample 2 Sample 3 10 20 -9 192 15 13 -1 284 20 11 8 376 25 11 23 460 30 11 36 538 35 10 50 610 40 9 62 675 45 11 71 733 50 12 80 781 55 10 89 819 60 9 99 848 65 9 105 871 70 9 110 890 75 9 119 905 80 9 125 917 85 9 133 928 90 9 152 937 95 9 166 945 100 9 177 951 17 105 9 190 957 110 9 205 960 115 8 223 963 120 9 234 965 125 9 243 968 130 9 255 967 135 9 267 959 140 11 276 959 145 10 284 958 150 9 293 960 155 9 303 965 160 9 313 968 165 9 318 967 170 9 318 961 175 9 320 957 180 9 324 956 Absorbance (420 nm) 25 20 15 10 5 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 Time [s] Figure 10.1: Plot of absorbance at 420 nm against time for sample 1. Figure 10.1 shows the change in absorbance with time for sample 1, which was taken approximately 2.5 hours into the experiment, before the depletion of glucose. The 18 absorbance seems to stabilize and no growing trend can be observed. This indicates no or very low enzyme activity. In other words, 𝑑𝐴𝑏𝑠 ≈ 0 s −1 𝑑𝑡 This result is as expected, as β-galactosidase should not be present at the beginning of the experiment. 350 Absorbance (420 nm) 300 250 y = 2.171x - 33.532 R² = 0.995 200 150 100 50 0 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 -50 Time [s] Figure 10.2: Plot of absorbance at 420 nm against time for sample 2 with trendline added to the linear part of the curve. The equation of the trendline and its coefficient of determination, R2, are also shown. Figure 10.2 shows the change in absorbance with time for sample 2 with a trendline added to the linear part of the curve. The absorbance grew throughout the experiment, although a plateau seems to be reached around the last four data points. The instantaneous change in absorbance with time is given by the slope of the trendline, meaning that 𝑑𝐴𝑏𝑠 = 2.171 s−1 𝑑𝑡 19 1200 Absorbance (420 nm) 1000 800 600 y = 74.183x + 145.64 R² = 0.9902 400 200 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 Time [s] Figure 10.3: Plot of absorbance at 420 nm against time for sample 3. Maximum absorbance is estimated from the mean of the values in the plateau of the graph and indicated as a horizontal line. A fitted curve found by regression is included in the linear part of the graph. The equation of the trendline and its coefficient of determination, R2, are also shown. Figure 10.3 shows the change in absorbance with time for sample 3 with a trendline added to the linear part of the curve. The maximum absorbance at 420 nm was determined from an average of the values in the plateau of the graph: 𝐴𝑏𝑠𝑚𝑎𝑥 = 962.3 Also, the slope of the trendline in Figure 10.3 gave 𝑑𝐴𝑏𝑠 = 74,18 s−1 𝑑𝑡 The initial concentration of ONPG was calculated as follows: µmol 𝑐1 𝑉1 2.5 mL ∙ 1mL 𝑐2 = = = 0.278 µmol/mL 𝑉2 9 mL mol µmol ONPG0 = 𝑐2 ∙ 2.5 mL = 0.278 µ mL ∙ 2.5 mL = 0.695 µmol From this, V0 was calculated for the second and the third sample. For sample 2: 20 𝑉0 = µmol ONPG0 𝑑Abs 0.695 ∙ = ∙ 2.171 ∙ 60 = 0.09408 µmol/min Absmax 𝑑𝑡 962.3 For sample 3: 𝑉0 = µmol ONPG0 𝑑Abs 0.695 ∙ = ∙ 74.18 ∙ 60 = 3.214 µmol/min Absmax 𝑑𝑡 962.3 For sample 1, V0 = 0, as dAbs/dt = 0. Once again it is assumed that the relationship between OD and cell concentration is linear in the observed range and the fact that cell concentration is known to be 0.02085 g/mL when OD660 nm is 2.62 is exploited. It is also known that 0.3 mL of the sample is mixed with buffer solution to prepare it for OD measurement: Weight of biomass = 0.02085 g 𝑂𝐷 ∙ ∙ 0.3 mL mL 2.62 For sample 2, OD is 2.62 and the weight of biomass is simply 0.02085 g ∙ 0.3 mL = 0.00625 g mL For sample 3, OD is 13.4 and the weight of biomass is 0.02085 g 13.4 ∙ ∙ 0.3 mL = 0.0320 g mL 2.62 The specific enzyme activity is given by Specific enzyme activity = 𝑉0 Weight of biomass For sample 2, this gives Specific enzyme activity = 0.09408 = 15.06 µmol/min ∙ g 0.00625 For sample 3: Specific enzyme activity = 3.214 = 100.4 µmol/min ∙ g 0.0320 21