DOCUMENT TITLE - Plymouth City Council

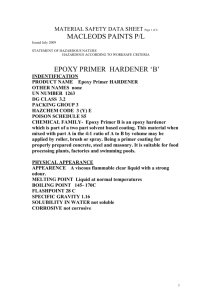

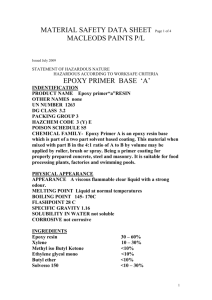

advertisement

HSPS04 – HAZARDOUS SUBSTANCES RISK ASSESSMENT FORM EXAMPLES Health, Safety and Wellbeing Team SECTION 1. Identify Hazardous Substances and hazards related to them Number Substance 1 Binder Part A Epoxy resin 2 Binder Part B Epoxy resin 3 Bauxite 4 Propane – heating fuel Version 4 November 2011 Hazard(s) very toxic, toxic, harmful, corrosive, irritant, flammable, explosive etc. Irritant/harmful –danger of serious damage to health by prolonged contact with skin, very toxic to aquatic organisms + may cause long term adverse effects to aquatic environment. Toxic/corrosive –may cause harm to unborn child, may cause long term adverse effects to aquatic environment. N/a Extremely flammable, heavier than air, gas/air mixtures are explosive, asphyxiant at high concentrations. Form (solid, liquid, gas etc.) WEL From safety data sheet 8 hr limit 15 min limit Flash point + explosive limits R phrases Liquid 100-105ºC 36/37, 43,45, 48/21, 50,53 Liquid 91ºC 21/22, 24/25,34, 36/37, 39, 43, 45,48/21,53,61 -105ºC 2-9.5% 12 Granules (dusty) LPG 10 mg/m³ Not protectively marked SECTION 2: Who might be exposed, how often, and how much? – identify any secondary hazards from mixing substances. Substance No. 1,2,3,4 4 Staff group/other + how many Frequency + length of exposure exposed 6 Highways operatives Daily for 2 operatives, occasional for others. Refuse staff near store at Prince Daily Rock depot Level of exposure High, med, low Up to 44 Kg epoxy resin, + up to 1000 Kg Propane. Up to 4xfull 47 Kg cylinders + 4 x empty Secondary hazard from mixtures? None None SECTION 3. How might exposure occur? - routes of entry and injuries or health effects that could result. Route of exposure ✔ if yes Substance No. Inhalation ✓ 1,2,3,4, Ingestion Absorption Injection Skin ✓ 2 ✓ 1,2 Eyes Other ✓ 1,2 Health Surveillance/ Monitoring arrangements Consequence of exposure 1,2-Irritant/harmful. 3 – nuisance.4 – Headache, vomiting, disorientation. Toxic/corrosive 1,2 – sensitisation. 1,4 – irritant. 2 – toxic, corrosive, may cause cancer. 1,2- irritant. 3 – nuisance. None None HSE guidance on dermatitis for operatives. Visual checks by supervisor/OH. N/a SECTION 4. Emergency procedures and waste disposal arrangements Substance/No. 1,2,(3 inhalation, eyes + ingestion) 4 – inhalation. 1,2, 3, 4 Emergency procedures – First aid actions, spillage procedures, fire/explosion etc. First aid – Inhalation: remove to fresh air. Seek medical attention if symptoms persist. Eyes: flush thoroughly with lots of water. If irritation persists, seek medical attention. Skin: wash with plenty of soap + water. Ingestion: don’t induce vomiting. Give water + seek medical attention. Spillage/leak – absorb in inert material (sand or vermiculite) + sweep into suitable containers for disposal as hazardous waste by specialist contractor (dispose of brushes etc. as contaminated waste). N/a Eliminate sources of ignition + ventilate thoroughly. Waste disposal arrangements React 1+2 to form inert polymer, then dispose via Chelson Meadow transfer station as controlled waste. – same disposal route as 1,2.4 – return cylinders to supplier. Dispose as hazardous waste to a specialist contractor – do not allow spillages to contaminate watercourse/sewers. 1,2,3, 4 Fire – Use CO2, foam, dry powder or water fog only. Fire fighters must wear BA. Water fog only – clear area due to risk of explosion. Remaining waste must be treated as hazardous. SECTION 5. Risk Controls - For each substance identified in Section 1, list existing control measures. Substance No. 1,2,3,4 1,2 3 4 Existing controls in place to reduce risk – you must check that these controls are actually working: eg general ventilation; LEV; fume cupboard; gloves (specify type); eye protection (specify); RPE (specify); protective clothing (specify); DSEAR zone; no ignition sources; minimise amounts; training; other (specify). Good general ventilation in storage area, work in open air. Smoking, eating, drinking banned + hand/eye wash facilities provided at store/on vehicle. Training in system use to BS/EN/ISO 9002 and ADR. First aid kit on vehicle + all work within City boundary close to emergency services. 2 man working at all times on the vehicle/highways. Epoxy resins delivered in ready to use 22Kg packs (x6 in storage, x2 in use per month). 1Propane cylinder 47 Kg on vehicle, (up to 8 in external store). PPE = pvc gloves, face shield/goggles (chem./impact resist), overalls (close woven cotton, non -porous). PPE as for 1,2 + nuisance dust mask FFP3 (disposable). PPE = None – Propane is handled + refilled by delivery tanker driver. Name of Assessor(s) K.Paull, J.Morgan, P.Godsall, A.Rickard (Repeat form for continuation sheets) Residual Risk Reduced Risk Further action needed to reduce risks S P R Use of alternative Keygrip Thermoplastic Type 1+3 system heated to 225ºC. 4 3 12 4 3 12 1 3 3 3 1 4 SIGNED Department Tool box talks, staff training refreshers and questionnaires. Regular laundry service needed for overalls. Visual inspection by operatives/supervisor/OH for skin damage. First-aid training. Development + HR Service Unit Highways + H&S (S) Severity of health effect : Insignificant = 1; Minor = 2; Moderate = 3; Major = 4; Fatal/catastrophic = 5 (P) Probability of exposure: Very unlikely = 1; Unlikely = 2; Possible = 3; Likely = 4; Almost certain = 5 (R) Risk Rating = SxP: Low = 1-5; Medium = 6-10; High = 11-15; Very high = 16-25 S P R 2 3 6 4 2 8 4 2 8 2 3 6 2 3 6 SECTION 6. Best practice and vulnerable staff– in this section you need to identify the best practice or standards you have used in your assessment and identify any staff that may be considered to be more vulnerable. 6.1 Best Practice Standards Are there any relevant best practice standards or legal requirements which should be followed for the hazards being assessed? e.g. Council Policies, or guidance (corporate or departmental), legislation, HSE guidance or Approved Codes of Practice, British or European Standards, professional or trade guidance. SECTION 7.Action Plan List these: Trustseal Ltd. BBA Certificate method statements, Safety Data sheets + instructions for safe use. COSHH Reg’s 2002, DSEAR 2002, CHIP 2002, ADR and the Carriage Reg’s 2004. PCC H&S Policy, and COSHH Assessment Performance Standard. HSE RR079 ‘An assessment of skin sensitisation by the use of epoxy resin in the construction industry’ 2004. See HSE web site www.hse.gov.uk 6.2 Vulnerable Staff Are there any staff who may be particularly vulnerable and at risk. If so, a personal risk assessment should be carried out. List these: None known, but could include asthmatics. e.g. young persons (under 18); new and expectant mothers, staff with disabilities or health conditions that might increase risk. – list how the further action required, as identified in Section 5, will be undertaken. Hazard Action Required Epoxy resins A+B Specialist laundry service weekly for overalls. Monthly visual inspection of exposed skin for sensitisation reaction. Hot + cold materials Emergency first aid training for Gangers + Lead Hands (1/2 - 1 day) Costs / resources required Brief instruction/ training for supervisor – contact OH provider. Target Date Jan 2006 Jan 2006 Action by whom? K.Paull to arrange Eg PCFE Appointed person course £24p.p Mar 2006 K.Paull to arrange Completion Date I confirm that this Hazardous Substances Risk Assessment is an accurate reflection of the risks and controls in place YES / NO The further action required, as outlined in the Action Plan above, will be achieved by the target dates YES / NO – see below* *Manager’s comments (if further resources are required etc.)………………………………………………..…………………………………………. ……………………………………………………………………………………………………………………………………………..……… Signed by responsible manager: NAME…….………………………………………………Signature……….………………………………….Date…..……………………………….. Review date ……………………………………………. For guidance on completing this form, please refer to Council Health & Safety Performance Standard HSPS04 ‘Hazardous Substance Risk Assessment’ available on the Health, Safety & Wellbeing Document Library, where further copies of this form can alsobe obtained.