Hypothesis Test: Golf Cart Assembly Time

advertisement

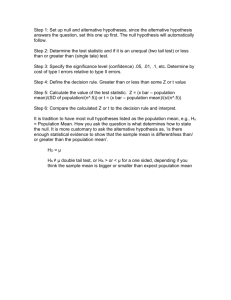

The management of White Industries is considering a new method of assembling its golf cart. The present method requires 42.3 minutes, on the average, to assemble a cart. The mean assembly time for a random sample of 24 carts, using the new method, was 40.6 minutes, and the standard deviation of the sample was 2.7 minutes. Using the .10 level of significance, can we conclude that the assembly time using the new method is faster? Since sample size is smaller than 30, we use t-statistics m=40.6 s= 2.7 null hypothesis: m = 42.3 alternative hypothesis: m<42.3 t-statistics = (40.6-42.3)/(2.7/241/2) = -3.0845 < -t(0.1/2, 23) = -1.738 so reject null hypothesis, that is assembly time using the new method is faster. if have more question, write w_zhou75@yahoo.com