Economic analysis of using refinery vacuum residue in a green

advertisement

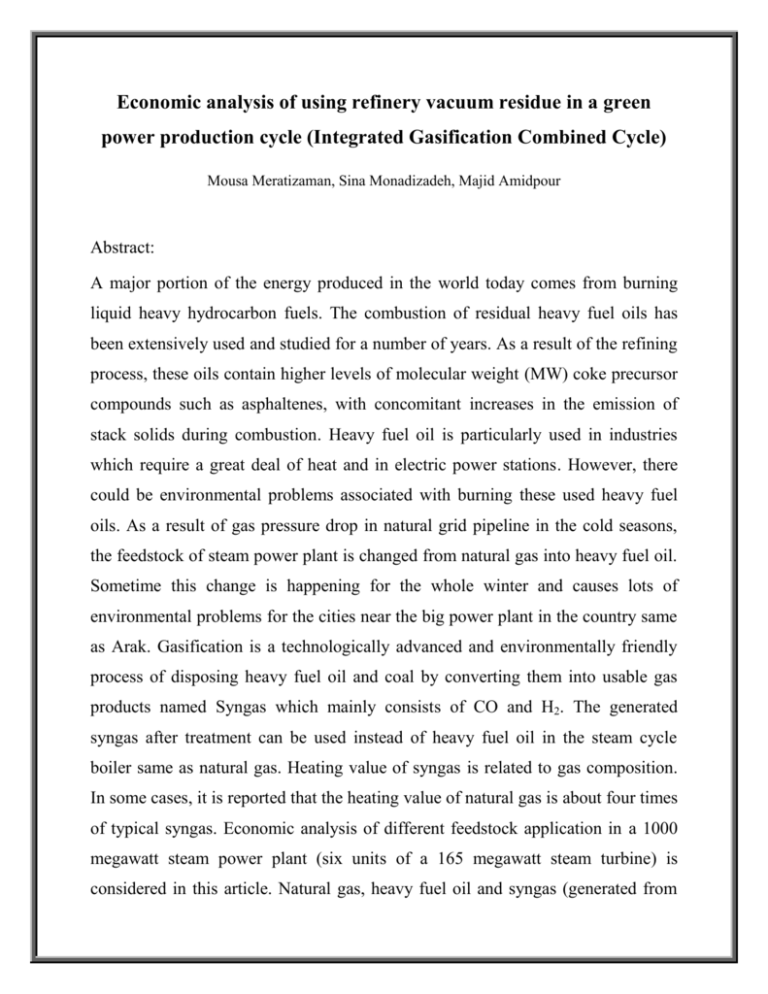

Economic analysis of using refinery vacuum residue in a green power production cycle (Integrated Gasification Combined Cycle) Mousa Meratizaman, Sina Monadizadeh, Majid Amidpour Abstract: A major portion of the energy produced in the world today comes from burning liquid heavy hydrocarbon fuels. The combustion of residual heavy fuel oils has been extensively used and studied for a number of years. As a result of the refining process, these oils contain higher levels of molecular weight (MW) coke precursor compounds such as asphaltenes, with concomitant increases in the emission of stack solids during combustion. Heavy fuel oil is particularly used in industries which require a great deal of heat and in electric power stations. However, there could be environmental problems associated with burning these used heavy fuel oils. As a result of gas pressure drop in natural grid pipeline in the cold seasons, the feedstock of steam power plant is changed from natural gas into heavy fuel oil. Sometime this change is happening for the whole winter and causes lots of environmental problems for the cities near the big power plant in the country same as Arak. Gasification is a technologically advanced and environmentally friendly process of disposing heavy fuel oil and coal by converting them into usable gas products named Syngas which mainly consists of CO and H2. The generated syngas after treatment can be used instead of heavy fuel oil in the steam cycle boiler same as natural gas. Heating value of syngas is related to gas composition. In some cases, it is reported that the heating value of natural gas is about four times of typical syngas. Economic analysis of different feedstock application in a 1000 megawatt steam power plant (six units of a 165 megawatt steam turbine) is considered in this article. Natural gas, heavy fuel oil and syngas (generated from gasification of fuel oil) are selected as steam power plant feedstock. The main parts of natural gas and heavy fuel oil steam cycle are boiler feed pump, three pressure level boiler and steam turbine but for syngas feedstock cycle, preheater, gasifier and gas treatment unit are added to previous instruments. Annualized cost of system (ACS) is chosen as an economic analyzing approach. Keywords: Gasification, Fuel oil, Syngas feedstock, Steam cycle power plant, Annualized cost of system