Environmental analysis of different scenarios of power generation in

advertisement

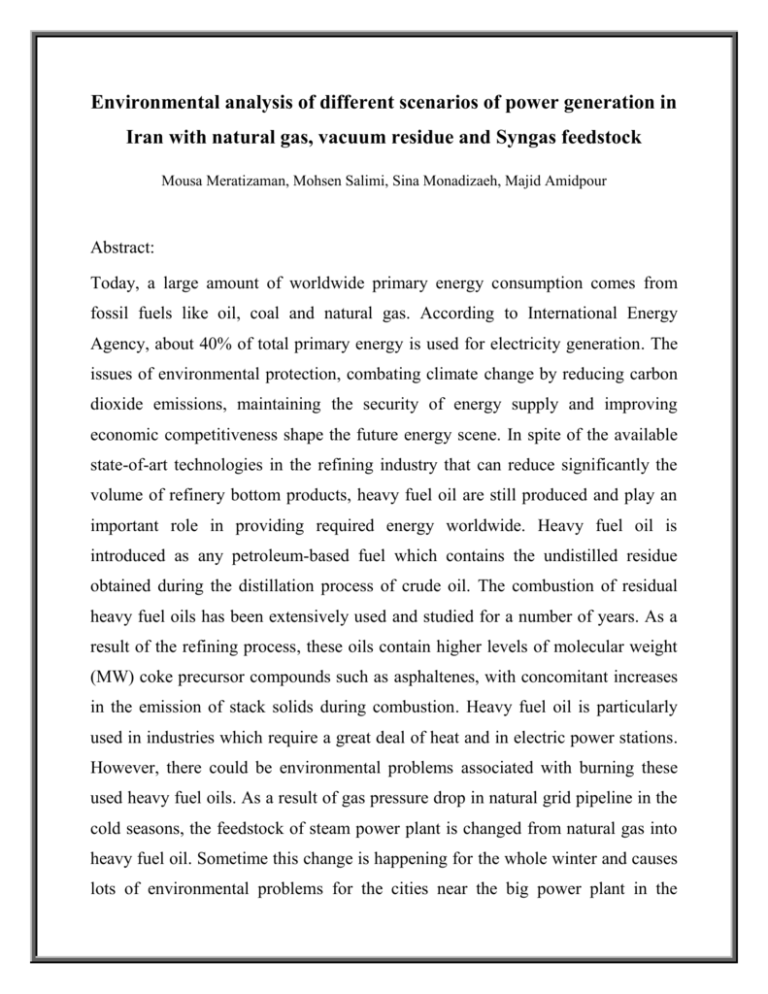

Environmental analysis of different scenarios of power generation in Iran with natural gas, vacuum residue and Syngas feedstock Mousa Meratizaman, Mohsen Salimi, Sina Monadizaeh, Majid Amidpour Abstract: Today, a large amount of worldwide primary energy consumption comes from fossil fuels like oil, coal and natural gas. According to International Energy Agency, about 40% of total primary energy is used for electricity generation. The issues of environmental protection, combating climate change by reducing carbon dioxide emissions, maintaining the security of energy supply and improving economic competitiveness shape the future energy scene. In spite of the available state-of-art technologies in the refining industry that can reduce significantly the volume of refinery bottom products, heavy fuel oil are still produced and play an important role in providing required energy worldwide. Heavy fuel oil is introduced as any petroleum-based fuel which contains the undistilled residue obtained during the distillation process of crude oil. The combustion of residual heavy fuel oils has been extensively used and studied for a number of years. As a result of the refining process, these oils contain higher levels of molecular weight (MW) coke precursor compounds such as asphaltenes, with concomitant increases in the emission of stack solids during combustion. Heavy fuel oil is particularly used in industries which require a great deal of heat and in electric power stations. However, there could be environmental problems associated with burning these used heavy fuel oils. As a result of gas pressure drop in natural grid pipeline in the cold seasons, the feedstock of steam power plant is changed from natural gas into heavy fuel oil. Sometime this change is happening for the whole winter and causes lots of environmental problems for the cities near the big power plant in the country same as Arak. Gasification process is an energy conversion technology in which the solid or heavy fuel oil feedstock are partially oxidized with oxygen and steam to produce syngas (mainly a mixture of carbon monoxide and hydrogen) which can be used either for the conversion into different valuable compounds (e.g. hydrogen, methanol, ammonia, liquid fuels) or to generate power. Environmental analysis of different feedstock application in a 1000 megawatt steam power plant (six units of a 165 megawatt steam turbine) is considered in this article. Natural gas, heavy fuel oil and syngas (generated from gasification of fuel oil) are selected as steam power plant feedstock. The main parts of natural gas and heavy fuel oil steam cycle are boiler feed pump, three pressure level boiler and steam turbine but for syngas feedstock cycle preheater, gasifier and gas treatment are added to previous instruments. SO2, CO and CO2 production of each feedstock are compared together. Keywords: Gasification, Environmental Analysis, Fuel oil, Syngas feedstock, Steam cycle power plant