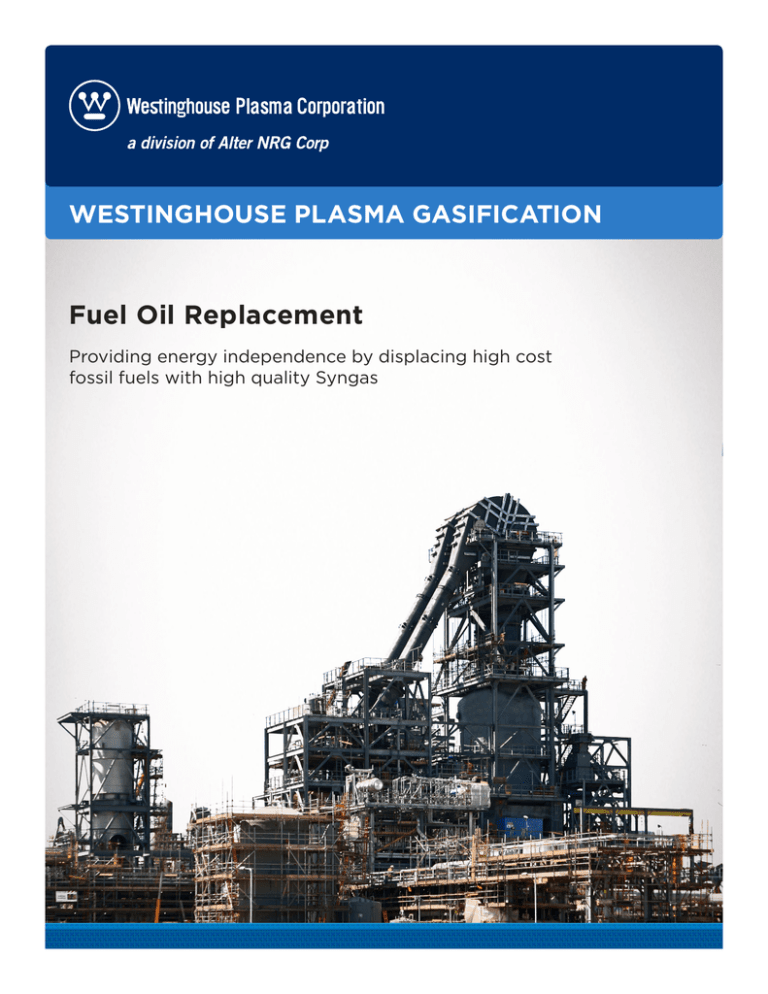

Fuel Oil Replacement

advertisement

WESTINGHOUSE PLASMA GASIFICATION Fuel Oil Replacement Providing energy independence by displacing high cost fossil fuels with high quality Syngas Westinghouse Plasma Gasification has Significant Commercial Advantages WESTINGHOUSE PLASMA CORP. Minimal feedstock preparation High reliability • • and a one stage shredding of the commercially proven and capable of processing a variety of waste materials to generate a commodity grade syngas. Syngas is a versatile product that can Operates in rugged industrial applications material The Westinghouse Plasma Gasification technology is Typically a pre-sorting of recyclables • Handles a wide range of feed compositions Over 500,000 hours and 20 years of industrial use on the plasma torches • High moisture content Low emissions and waste by-products • High inert content • • Blend any number of solid or liquid natural gas • feedstock’s • aggregate • increases project economics Vitrified Slag is inert/non-leaching and is being used as a construction Ability to blend feedstocks reduces project feedstock risk and significantly be used to replace fossil Syngas, after cleanup, burns clean like Low Greenhouse Gas Footprint when compared to alternative methods of fuels and generate power. creating power Alter NRG is your key partner in Fuel Replacement CLEANUP via Plasma Gasification of Waste materials. We provide a scalable solution SYNGAS capable of replacing anywhere from 50,000 bbls/ yr of fuel oil to over a million WASTE bbls/yr per facility. With Plasma Torches today’s price of oil over Air or Oxygen Slag & Recovered Metals $100.00 per barrel there is no better time to secure energy independence. Westinghouse Plasma Corp. provides a complete design build solution for the fuel replacement market. Our project scope is designed to minimize execution risk and provide the best possible solutions and service for our customers. From detailed facility engineering to the start-up and commissioning of your facility, Westinghouse Plasma Corp. is with you every step of the way. Diverse Gasification Portfolio Standard platforms Engineering services P5 • Feasibility Study • Replaces up to 50,000 bbls/yr of fossil fuel • Design Basis Memorandum (DBM) • 30 to 100 tpd of Waste • Process Design Package (PDP) • Replaces up to 5 MW electrical W 15 • Replaces up to 150,000 bbls/yr of fossil fuel • 100 to 290 tpd of Waste • Replaces up to 15 MW electrical G 65 • Replaces up to 650,000 bbls/yr of fossil fuel • 450 to 1000 tpd of Waste • Replaces up to 50 MW electrical Scope of supply • Feed System • Plasma gasification reactor • Plasma torch systems • Slag solidification system • Initial syngas cooling & cleaning • Syngas Cleaning Systems • Boiler Modifications (performed by partner COEN) REFUELING EXISTING POWER PLANT WITH WESTINGHOUSE PLASMA GASIFICATION • In the refueling configuration, the Westinghouse Plasma gasifier will process waste materials and create a commodity grade clean syngas. • The syngas is then fired into an existing boiler or turbine. Modifications to the existing burner system or combustion system will be made to ensure that the performance of the boiler or turbine is unchanged. • The syngas will likely represent less than 25% of the total fuel being delivered to the power station. • By controlling the amount of syngas as a percentage of the total delivered fuel, the facility will benefit from the significant economic and environmental attributes of the syngas while maintaining the original performance of the equipment. • By eliminating a portion of the fuel oil, the power plant will realize a dramatic decrease in fuel costs. Existing Boiler Configuration FUEL OIL OR LNG New Configuration FEED STOCK BOILER STEAM FUEL OIL Industrial Waste MODIFIED BOILER Municipal Waste SYNGAS Medical Waste Existing Turbine Configuration OR Waste Biomass FUEL OIL OR LNG GAS TURBINE ELECTRICITY Hazardous Waste Plasma Torches Tires etc. Refueling has many advantages, including: • • • • • Create Energy Independence Create an environmentally sustainable in country waste management solution Reduced reliance on expensive and volatile fossil fuel imports Improve the CO2 footprint of power generation facilities by reducing the amount of fuel oil Existing infrastructure can be used without major capital cost upgrades Air or Oxygen 100% SYNGAS GAS TURBINE Slag & Recovered Metals Westinghouse Plasma Gasification Solution Provides Significant Economic Returns Divert 1,000 tpd of Waste and create up to 650,000 bbls/yr of Replacement Fuel / yr WWW.WESTINGHOUSE-PLASMA.COM