2011-ENCH-4300-Final

advertisement

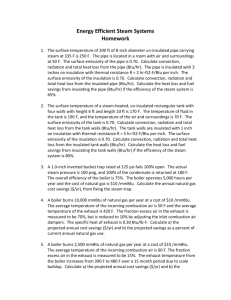

Carpet Waste Gasification: Technical, Economic, Environmental Assessment for Carpet Mills An Interim Presentation ENCH 4300—Capstone UT Chattanooga April 7, 2015 Advisor: Dr. Jim Henry Jordan Buecker Christopher Burns Katharine Davis Hemali Dholakia Kevin O’Brien Outline • • • • • • • • Problem Statement Principle of Gasification Methodology Proposed Systems Syngas Uses Environmental Analysis Economics Conclusions Problem Statement • 250 tons per day of post-consumer carpet (PCC) • Currently pay disposal fees • Reclaim a portion of the chemical energy from the PCC Problem Statement • PCC has lower heating value of 8,800 Btu/lb o Bituminous coal LHV = 11,000 Btu/lb o Natural gas LHV = 20,000 Btu/lb • Gasification Processes PCC considered o Produce syngas • Syngas LHV = 8,000-12,000 Btu/lb Principle of Gasification Methodology • 250 tons/day of post consumer carpet • Carpet composition (wt%) Component Percentage of Carpet (wt%) Polypropylene (PP) 17 Calcium Carbonate (CaCO3) 35 Polyethylene Terephtalate (PET) 6 Nylon 6 (N 6) 17 Nylon 6,6 (N 6,6) 14 Styrene Butadiene Rubber (SBR) 11 Percentage removed pre-gasification (wt%) 80 100 Methodology Material PP CaCO3 PET SBR N66 Heat of Combustion (BTU/lb) -18600 800 -9500 -18900 -13800 Flowrate (lb/hr) 1700 700 630 1100 1400 MMBTU/hr -32 0.6 -6 -21 -19 Total 79 MM BTU/hr Methodology • Employed ChemCad modeling software • Material balance • Energy balance Proposed Systems Air Gasifier Proposed Systems Air Gasifier • N2 presence reduces heating value • Produces NOx Proposed Systems O2 Gasifier Proposed Systems O2 Gasifier • Capital increase due to N2 separation • Capital decrease due to volumetric flow from the gasifier Proposed Systems Steam Gasifier Proposed Systems Steam Gasifier • Lower Temperature • Produces CH4 (higher heating value syngas) Current Syngas Use Exhaust Steam Air Syngas Boiler Plant Use Potential Syngas Use Exhaust High Pressure Steam Air Boiler Syngas Steam Turbine Condensate Low Pressure Steam Condenser Potential Syngas Use Low Temp Exhaust Boiler High Pressure Steam Hot Exhaust Air Syngas Gas Turbine Steam Turbine Work Work Energy Recovery Gasifier Air O2 Steam MM BTU/h 58 58 35 BTU/lb PCCW 5800 5800 3500 Pollutants Gasifier lb CO2/MM Coal Coal lb/h CO2 BTU compare lb/h NOx compare Air 14000 O2 14000 Steam 11000 240 240 310 13% 13% 48% 300 -14% negligible negligible Interim Conclusions • Technologically and Environmentally Feasible • Economic Analysis will be performed Questions We Have • What were the strong points? • What can be improved upon? • What can be omitted?