Topic: PROCESS CAPABILITY

“Development of a Problem Solving Model

for the Hong Kong Textiles and Clothing

Industries” Project

HKRITA Ref. No. : RD/PR/001/07

ITC

Ref. No. : ITP/033/07TP

Copyright © 2009 – HKRITA. All rights reserved.

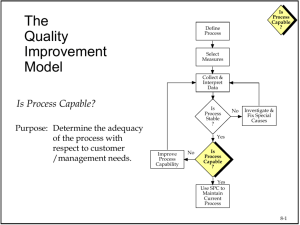

Why Study Process Capability

Process Capability Studies provide a baseline for us to

understand how the process is operating relative to the

specifications.

It is the first, thorough look at how variability is affecting

the process, and gives us metrics for quantifying that

variability.

Such studies also provide information regarding what the

process could do under best conditions, and thus gives a

performance target to shoot for.

Copyright © 2009 – HKRITA. All rights reserved.

Process Variation

Process Variation is the inevitable differences among

individual measurements or units produced by a process.

Sources of Variation

• within unit

(positional variation)

• between units

(unit-unit variation)

• between lots

(lot-lot variation)

• between lines

(line-line variation)

• across time

(time-time variation)

• measurement error

(repeatability & reproducibility)

Copyright © 2009 – HKRITA. All rights reserved.

Types of Variation

Inherent or Natural Variation

• Due to the cumulative effect of many small

unavoidable causes

• A process operating with only chance causes of

variation present is said to be “in statistical control”

Copyright © 2009 – HKRITA. All rights reserved.

Types of Variation

Special or Assignable Variation

• May be due to

a) improperly adjusted machine

b) operator error

c) defective raw material

• A process operating in the presence of assignable causes of

variation is said to be “out-of-control”

Copyright © 2009 – HKRITA. All rights reserved.

Process Capability

Process Capability is the inherent reproducibility of a process’s

output. It measures how well the process is currently behaving

with respect to the output specifications. It refers to the uniformity

of the process.

Capability is often thought of in terms of the proportion of output

that will be within product specification tolerances. The frequency

of defectives produced may be measured in

a) percentage (%)

b) parts per million (ppm)

c) parts per billion (ppb)

Copyright © 2009 – HKRITA. All rights reserved.

Process Capability

Process Capability studies can

• indicate the consistency of the process output

• indicate the degree to which the output meets

specifications

• be used for comparison with another process or

competitor

Copyright © 2009 – HKRITA. All rights reserved.

Conventional Use of Distribution Curves

Upper Limit

Lower Limit

We will use a smooth curve to

represent an actual process

distribution

Representative

Curve

15

20

25

X Dimension

Copyright © 2009 – HKRITA. All rights reserved.

30

Process Capability vs Specification Limits

a)

b)

c)

a) Process is highly capable

b) Process is marginally capable

c) Process is not capable

Copyright © 2009 – HKRITA. All rights reserved.

Three Types of Limits

Specification Limits (LSL and USL)

• created by design engineering in response to customer

requirements to specify the tolerance for a product’s

characteristic

Process Limits (LPL and UPL)

• measures the variation of a process

• the natural 6σ

σ limits of the measured characteristic

Control Limits (LCL and UCL)

• measures the variation of a sample statistic (mean, variance,

proportion, etc)

Copyright © 2009 – HKRITA. All rights reserved.

Three Types of Limits

Distribution of Individual Values

Distribution of Sample Averages

Copyright © 2009 – HKRITA. All rights reserved.

Process Capability Indices

Two measures of process capability

• Process Potential

– Cp

• Process Performance

– Cpu

– Cpl

– Cpk

Copyright © 2009 – HKRITA. All rights reserved.

Process Potential

The Cp index assesses whether the natural

tolerance (6 σ) of a

process is within the specification limits.

Cp

=

Engineering Tolerance

Natural Tolerance

=

USL − LSL

6σ

LSL

Copyright © 2009 – HKRITA. All rights reserved.

USL

Process Potential

Historically, a Cp of 1.0 has indicated that a process is

judged to be “capable”, i.e. if the process is centered

within its engineering tolerance, 0.27% of parts produced

will be beyond specification limits.

Cp

Reject Rate

1.00

0.270 %

1.33

0.007 %

1.50

6.8 ppm

2.00

2.0 ppb

Copyright © 2009 – HKRITA. All rights reserved.

Process Potential

a)

c)

b)

a) Process is highly capable (Cp>2)

b) Process is capable (Cp=1 to 2)

c) Process is not capable (Cp<1)

Copyright © 2009 – HKRITA. All rights reserved.

Process Potential

he Cp index compares the allowable spread (USL-LSL)

σ). It fails to take into

against the process spread (6σ

account if the process is centered between the

specification limits.

Process is centered

Process is not centered

Copyright © 2009 – HKRITA. All rights reserved.

Process Performance

The Cpk index relates the scaled distance

between the process mean and the nearest

specification limit.

C pu

=

USL − µ

3σ

C pl

=

µ − LSL

3σ

C pk

=

Minimum {C pu , C pl }

Copyright © 2009 – HKRITA. All rights reserved.

Process Performance

Cpk

Reject Rate

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

0.13 – 0.27 %

0.05 – 0.10 %

0.02 – 0.03 %

48.1 – 96.2 ppm

13.4 – 26.7 ppm

3.4 – 6.8 ppm

794 – 1589 ppb

170 – 340 ppb

33 – 67 ppb

6 – 12 ppb

1–

2 ppb

Copyright © 2009 – HKRITA. All rights reserved.

Process Performance

a)

b)

Cp = 2

Cpk = 2

Cp = 2

Cpk = 1

c)

Cp = 2

a) Process is highly capable (Cpk>1.5)

Cpk < 1

b) Process is capable (Cpk=1 to 1.5)

c) Process is not capable (Cpk<1)

Copyright © 2009 – HKRITA. All rights reserved.

Example 1

Specification Limits

:

4 to 16 g

Machine

Mean

Std Dev

(a)

10

4

(b)

10

2

(c)

7

2

(d)

13

1

Determine the corresponding Cp and Cpk for each

machine.

Copyright © 2009 – HKRITA. All rights reserved.

Example 1A

USL − LSL

16 − 4

=

6σ

6(4 )

Cp

=

= 0.5

C pk

16 − 10 10 − 4

USL − µ µ − LSL

= Min

;

=

Min

;

= 0.5

3σ

3σ

3(4 ) 3(4 )

Copyright © 2009 – HKRITA. All rights reserved.

Example 1B

USL − LSL

6σ

=

16 − 4

= 1.0

6(2 )

Cp

=

C pk

16 − 10 10 − 4

USL − µ µ − LSL

= Min

;

=

Min

;

= 1.0

3σ

3σ

3(2 ) 3(2 )

Copyright © 2009 – HKRITA. All rights reserved.

Example 1C

USL − LSL

6σ

=

16 − 4

= 1.0

6(2 )

Cp

=

C pk

16 − 7 7 − 4

USL − µ µ − LSL

= Min

;

=

Min

;

= 0.5

3σ

3σ

3(2 ) 3(2 )

Copyright © 2009 – HKRITA. All rights reserved.

Example 1D

USL − LSL

6σ

=

16 − 4

6(1)

Cp

=

= 2.0

C pk

16 − 13 13 − 4

USL − µ µ − LSL

= Min

;

=

Min

;

= 1.0

3σ

3(1)

3σ

3(1)

Copyright © 2009 – HKRITA. All rights reserved.

Process Potential vs Process Performance

(a) Poor Process Potential

Performance

LSL

USL

(b) Poor Process

USL

LSL

Experimental Design

Experimental Design

• to reduce variation

• to center mean

• to reduce variation

Copyright © 2009 – HKRITA. All rights reserved.

Process Potential vs Process Performance

a)

Cp = 2

Cpk = 2

b)

Cp = 2

Cpk = 1

c)

Cp = 2

Cpk < 1

Cp – Cpk ≡ Missed Opportunity

Copyright © 2009 – HKRITA. All rights reserved.

Process Stability

A process is stable if the distribution of

measurements made on the given feature is

consistent over time.

Stable Process

Time

Unstable

Process

Time

Copyright © 2009 – HKRITA. All rights reserved.

Graphical Representation of

Causes of Variations (Juran’s Trilogy)

“Special Cause” 變異?

變異

變異不是來自原有系統本身,

變異不是來自原有系統本身,

但是卻代表一種改變.

UCL

CL

LCL

Foc

u

s of

Si x

Sig

ma

“Common Cause” 變異?

變異

在流程內與生俱來的變異.

UCL

CL

LCL

Copyright © 2009 – HKRITA. All rights reserved.

Steps to Study Process Capability

• Select critical parameters for study

– Parameters from specifications, contract etc.

• Collect Data

– Collect 60 data or more as far as possible

– Define clearly the precision of each data (no. of significant figures, eg

up to 2 decimal places)

• Establish control

– Control the input to the process

• Analyze the data of the process collected

– Assumption : The process performance is a normal distribution

– Focus on mean and standard deviation of sample data

• Analyze the source of variation

– Find the factors that affect the process mean and process spread

(standard deviation)

• Establish process monitoring system

– Tool – Statistical Process Control

Copyright © 2009 – HKRITA. All rights reserved.

Summary on Indexes

Capability

index

Cp

Formula

Short or

long term

USL – LSL

6σST

Cpk

Pp

Short term

Includes

shift

and drift

Considers the

process

centering

No

No

No

Yes

Long term

Yes

No

Long term

Yes

Yes

Short term

USL – LSL

6σLT

Ppk

Copyright © 2009 – HKRITA. All rights reserved.

Example 2 – Customer request a metal bar

from 2 suppliers

Customer require 2mm +/- 0.1mm

2 +/- 0.1 mm

Supplier A

Supplier B

Supplier A

Cp = 1.11

Supplier B

Cp = 0.62

Lower Specification Limit

(LSL = 1.9mm)

Mean

(μ= 2 mm)

Upper Specification Limit

(USL = 2.1mm)

Copyright © 2009 – HKRITA. All rights reserved.

Location Change

If the center of distribution was shifted, customer may not happy even receive a high Cp value.

Cp can not reflect the condition of the center shift !!

Same Cp value

Distribution B

Distribution A

Out of

specification

LowerSpecificationLimit

(LSL)

Mean

(μ)

UpperSpecificationLimit

(USL)

Copyright © 2009 – HKRITA. All rights reserved.

CpK Process Capability Index

• A measure of conformance (capability) to

specification

• Compares sample mean to nearest specification

against distribution width

CpK can more precisely reflect the capability of distribution.

Copyright © 2009 – HKRITA. All rights reserved.

Example 3 –

Process Variation on Two Suppliers

Supplier A

Supplier A

Cp = 1.11

CpK = 0.22

μ = 1.92 mm

LSL = 1.9 mm

Supplier B

Supplier B

Cp = 1.11

CpK = 1.11

μ = 2.00 mm

Mean

(μ= 2.0 mm)

USL=2.1mm

Remark:

Same SD but different Central

Tendency affects Cpk seriously

but remains same for Cp.

Copyright © 2009 – HKRITA. All rights reserved.

- THE END -

Copyright © 2009 – HKRITA. All rights reserved.