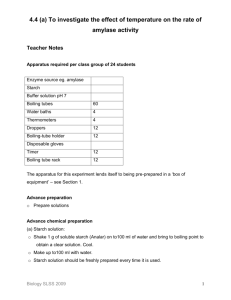

Nov2012_NABT_EnzAdv_Amylase

advertisement

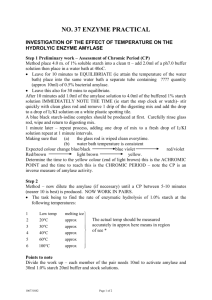

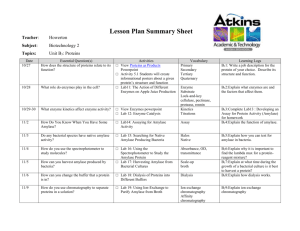

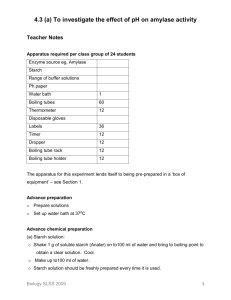

Enzyme Adventures – Amylase Ellyn Daugherty San Mateo Biotech Career Pathway Ellyn@BiotechEd.com www.BiotechEd.com Complete the card in the tri-fold brochure. Place a check at the top of the card to get a biotech text, lab manual, & CD sent free from EMC Paradigm. Now, while you wait, PLEASE look through the PPT handout (and the lab handout) so you know what’s coming! In Biotech, companies find a product of interest (amylase) and make sure to have assays to show it’s presence, activity, & concentration Amylase is an enzyme that catalyzes starch digestion. It is used commercially in several ways including: 1) Remove starch in products 2) Produce sugar from starch 3) Processing of cellulostic biofuel The goal of The rAmylase Project is to • Learn how to assay for a protein of commercial interest (amylase) • Transform cells to produce that protein (using pAmylase and C2523 cells) • Scale-up cells to volumes where amylase can be purified and assayed Absorbance (a.u) Ion Exchange Chromatography 0.35 0.3 0.25 0.2 0.15 0.1 0.05 0 -0.05 0 5 Fractions (#) 10 The rAmylase Project Model of rDNA/protein Business < Chapters 1-5 Basic SLOP < Lab 5f Amylase PAGE (revised) < Lab 6e Amylase Producing Bacteria < Lab 6c Amylase Activity Assay (revised) < Lab 6d Amylase ELISA and W Blot (new) < Labs 7a/7b/7f/7g Amy Spectrophotometry < Lab 8b Restriction Digestion of pAmylase < Lab 4j/8b/8g DNA Gel Electrophoresis (revised) < Lab 8c pAmy Transformation of E. coli < Lab 9c/9d Amy Ion-Ex Chromatography < Lab 8g/4h Genomic & plasmid DNA Isolation < Lab 13i Amylase Gene PCR (new) Lab 6c Amylase Activity Assay Lab 6c (abbrev) Confirm the Protein’s Activity Procedure * Caution: Treat saliva as a biohazard. Wear gloves and dispose of properly. * Note: Change tips with each dispensing. 1. Each partner, collect approximately 500 µL of saliva into a 1.7 mL tube. 2. Obtain a clean, 24-well plate. Study the labels heading the columns and rows. 3. Place 1 mL of 2% starch solution (Alfa Aesar® modified soluble starch solution in dH2O) in the wells of columns 1-5 rows A, B, and C, a total of 15 wells. Work quickly for steps 4-8. 4. To Column 1, add 300 µL of human salivary amylase solution from Partner 1 to each of the starch-filled wells. Mix well. 5. To Column 2, add 300 µL of human salivary amylase solution from Partner 2 to each of the starch-filled wells. Mix well. 6. To Column 3, add 300 µL of 5 mg/mL bacterial amylase (in 100 mM KH2PO4, 6 mM NaCl, pH 6.9) to each of the starch-filled wells. Mix well. 7. To Column 4, add 300 μL of 1 mg/mL bacterial amylase (in 100 mM KH2PO4, 6 mM NaCl, pH 6.9) to each of the starch-filled wells. Mix well. 8. To Column 5, add 300 μL of the 100 mM KH2PO4, 6 mM NaCl, pH 6.9 buffer to each of the starch-filled wells. Mix well. 9. Allow the samples to incubate at room temperature for 10 min. While waiting, identify the positive and negative controls in this experiment. Make and record predictions as to what may occur in each well, including the expected color changes. 12. Add 20 µL of iodine to each well. Mix each for 2 seconds with the pipet tip. 13. Place the 24-well tray on a piece of white paper, out of direct light. Iodine decolorizes in light. 14. After 10 min, measure the amount of starch breakdown in each well by recording the degree of lightening of the iodine solution from black (0) to a light golden-brown color (5). My Professional Goals • Biotechnology programs in every high school, CTE center, and community college, tailored to the student population and industry and community needs • Aligned and articulated programs in HS and CC so that teenagers and adults have the same platform from which to enter specialized programs • To make it as easy as possible for educators to do the other 2 SMBCP Link IRC Link New Things/Upd ates SW Lists All of LN’s PPTs Current Events LN’s workshops www.BiotechEd.com Materials Lists Master and Descriptive Materials Lists www.sargentwelch.com/biotech Get even more help… www.emcp.com/biotech Cheryl Monson CMonson@emcp.com for books/IRC help www.SargentWelch.com/biotech Jana Penders for materials/equipment support Jana_Penders@vwreducation.com