Basic principle of l..

advertisement

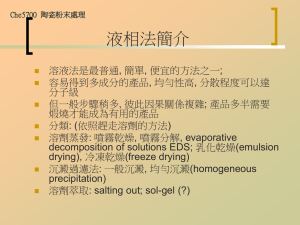

Che5700 陶瓷粉末處理

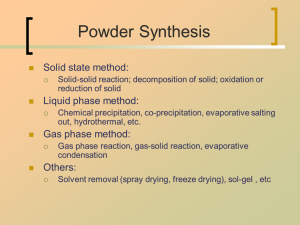

Introduction to Liquid Phase

Synthesis

Very common; simple; cheap;

Easy to get multi-component product, high uniformity,

dispersion in atomic scale;

Often more steps; complex inter-relationship; often

need calcination to get final useful product

Classification: (the way to remove solvent)

Solvent evaporation: spray drying, spray

decomposition, evaporative decomposition of solutions

EDS; emulsion drying, freeze drying

Precipitation-filtration: ordinary process; homogeneous

precipitation

Solvent extraction: salting out; sol-gel (?)

Che5700 陶瓷粉末處理

Process Introduction

Precursor in solvent (aqueous or organic) one or

several precursors chemical reaction (additive,

temp., etc.) separation from solvent postprocessing (washing, drying, etc.) product powder

Precipitation method: co-precipitation, homogeneous

precipitation, emulsion precipitation, hydrothermal

precipitation, hydrolytic precipitation (referring to solgel, alkoxide was hydrolyzed)

Important parameters: pH, temperature, time,

precipitation agent, quantity, rate of addition, method

of addition, type of cation, type of solvent and quantity,

reactor size and shape, other additives, stirring,

atmosphere and pressure (e.g. in autoclave) VERY

COMPLEX; often rely on experimental design

UO2 nuclear fuel

rod material;

Reaction: UO2F2

+ (NH4)2CO3

(NH4)4UO2(CO3)3

+ 2 NH4F

Complex steps

experimental

design to find

optimal

condition quickly,

e.g. Taguchi

method,

Plackett –

Burman etc.

•Top figure: a,b,c –

particle size distribution

after precipitation,

washing/drying and

calcination, agglomeration

during washing and

drying is obvious

•Bottom figure: relation

between average size

(after calcination) and

sintered density; only

qualitative in nature.

* Taken from JS Reed; precipitation occurs when two

chemical reacting with each other, formation of particles –

described by the theory of nucleation and growth

Che5700 陶瓷粉末處理

Expression of supersaturation

supersaturation: C = C – C or m, x

Supersaturation ratio: = C/C

Relative supersaturation: C = C/C; x + 1 = x/x

Dimensionless growth affinity: = /RT

For Activity & activity coefficient of ions: thermodynamic

equations such as Debye-Huckel equation

i (i i ) & i i RT ln ai

eq

o

ai i xi & xi i x

{1 ln( / ) / ln(x / xeq )}RT ln(1 x )

eq

Che5700 陶瓷粉末處理

Electrolytic Solutions

• Behavior of ions: non-ideal solution; due to strong

interaction between ions

• electrical neutrality: z+ NA + z- NB = 0 (Aν+Bν- = ν+

A z+ +ν- Bz-; ν+ z+ +ν- z- = 0;)

• mean ionic activity coefficient: γ±ν = (γA□) ν+ (γB□) νwhere ν=ν+ +ν• mean ionic molality: M±ν=MA ν+ MB ν• Debye-Huckel limiting law: ln γ± = - α∣z+ z-∣√I;

where I = ionic strength = ½ Σ zi2 Mi (over all ions);

α: parameter of system = f(T, solvent) (find it out in

handbooks for common solvents)

=RT ln; = (i/Ksp) 1/; = i

Ksp: ionic product at equilibrium; i = current ionic

product; ratio of these two values ~ supersaturation

Solubility

Thermodynamic data: mainly affected by

temperature, and solution environment (e.g. other

ions, pH,…)

a

G ( 2 1 ) RT ln( )

ao

C

a

S

Co ao

Solubility (2)

Temp. & pH effect: DCP =

dicalcium phosphate; HAP =

hydroxyapatite;

System of: Ca(OH)2-H3PO4 –

KOH – HNO3 – CO2 – H2O;

Ca/P = 1

2

A 2 B AB2( s )

2

2

o

K sp [ A ]o [ B ]

2

2

S [ A ][B ] / K sp

• ΔT: also used as a

measure of

supersaturation (as

shown in figure);

•Solubility often

increase with

temperature; (there are

also contrary cases, e.g.

CaCO3 solubility in

water decrease with

temperature; the reason

we get “scales”)

Che5700 陶瓷粉末處理

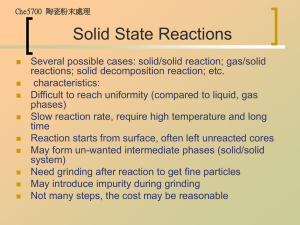

Nucleation

Several cases: homogeneous nucleation, heterogeneous

nucleation, secondary nucleation

For homogeneous nucleation: for its rate, we have

thermodynamic model or kinetic model

Thermodynamic model: changes between surface energy

and bulk energy, energy of formation of new crystals

= Ac – ( - ) Mc [Ac: crystal surface area; Mc:

crystal mass) when nucleus size reach some critical

value d /d(d) = 0 to get critical nucleus size d* =

4 Vm /(RT ln)

Finally to derive the rate equation:

Bo = C exp(- */kT) & * = 32 b 3 Vm2/(RT ln)2

S=

Che5700 陶瓷粉末處理

Kinetic Expression of Nucleation

Kinetic viewpoint: A1 + A1 = A2 + A1 = A3 …. A i+1 +..

A1 = monomer Then the following kinetic equations

Ci = condensation rate; Ei = evaporation rate

Under steady state d fi/dt = 0, and B.C. f1 = n1 =

constant; fG = 0 or constant (G: some critical size, e.g.

critical nucleus size)

dfi / dt Ci 1 fi 1 Ei fi Ci fi Ei 1 fi 1 I (i 1, t ) I (i.t )

I ao P / 2mkT(ao / 9kT )

1/ 2

I Z (i*)C (i*)n(i*)

exp(4ao 3 / 27k 3T 3 (ln P / Pe )2 )

3

Zeldovich factor

Che5700 陶瓷粉末處理

Solute Clustering & Nucleation

Taken from JCG, 89, 202-208, 1988.

Main viewpoint: solute molecules aggregate to form

clusters (precursor to nuclei), surface energy of cluster

may differ from large particles (different structure).

At 0oC, for water, 76% exist as clusters

One method to study cluster size and conc. : let

supersaturated solution stand for very long time

develop spatial distribution of clusters of different size,

measurement by density or opacity difference.

Indirectly, width for metastable zone, provide

information on cluster (narrow: cluster already exist,

easy to nucleation)

Typical cluster size: 4-10nm, ~ 103 molecules

Che5700 陶瓷粉末處理

Heterogeneous Nucleation

Reasons to heterogeneous nucleation:

larger complex size; impurity; wall of container;

liquid/air interface

Due to lowering of surface energy, (lowering

barrier to nucleation)

In a sense, co-precipitation: similar effect

Epitaxial growth: similar structure between nuclei

and impurity surface, therefore growth of nuclei

on this impurity surface

Used to make core-shell particles, core as seed

to shell particles

Complex ions

can increase size

of cluster, closer

to critical

nucleus size,

helpful to

nucleation;

Impurity also

influence

structure (phase)

of product

Che5700 陶瓷粉末處理

More on Nucleation

Taken from

TA Ring,

1996; data

for BaSO4

Che5700 陶瓷粉末處理

Secondary Nucleation

Under-saturated condition, existing nuclei

induce new nucleation – secondary nucleation

Reasons include:

Initial breeding;

Needle breeding

Contact breeding; Fluid shear etc.

parameters: degree of supersaturation, stirring,

collision between suspending particles

(frequency, energy, material of container etc)

Empirical relation: secondary nucleation rate Bo

~ (S-1)b MTj (rpm)h; where MT = quantity of

suspending particles

A Model on Secondary Nucleation

Taken from Botsaris, et. al. Chem. Eng. Sci., 52(20), 34293440, 1996;

Their concept: in supersaturated solution, existing embryos

(may be viewed as a result of coagulation between clusters),

they aggregate (due to van der Waals forces attractive forces),

if also seed, embryos move to seed, in the neighbor of seed:

high embryo concentration, they will aggregate to form new

nuclei, swept by fluid to become secondary nuclei, some may

aggregate with seed to make it bigger

Theory of rapid coagulation: - dn/dt = 8D r n2 = (4kT/3) n2

(by Smoluchowski) (particle movement by Brownian motion; n:

particle conc. r particle radius; D diffusion coefficient)

Botsaris: estimate secondary nucleation rate near a seed;

curve 7: assume cluster g = 622; At = seed surface area = 1.67

cm2/cm3; system: KCl-H2O; curve 6 first half: contact

nucleation; second half: similar to Botsaris’ theory

LH left-hand

左旋光結構

To demonstrate relation between seed and nuclei: use chiral

compound; low supersaturation: some effect, middle:

significant; high supersaturation: homogeneous nucleation

This impurity

show

inhibiting

effect

Che5700 陶瓷粉末處理

Induction Times

•

From start of generation of supersaturation until

observation of crystals, - induction time

• Techniques to observe crystals: turbidity, visual

observation, conductivity, or properties related to

concentration

• It include three parts:

ti = tr + tn + tg

ti : induction time;

tr: time required for attainment of stationary embryo

distribution (relaxation time)

tn: time for the formation of nucleus

tg: time for nucleus to grow into detectable crystals

* One possible barrier to nucleation: dehydration reaction of

ions

Che5700 陶瓷粉末處理

More on Induction Times

If tn: major part, nucleation dominate, tn ~ 1/Bo then ln(tn) or ln(ti)

vs ln() -2 should be linear

If tg: major, ti often becomes very long, its growth may be limited by

surface nucleation ln(ti) vs ln() -1 will be linear

sometimes, embryo

structure differs from

crystal, phase

change may become

barrier

Che5700 陶瓷粉末處理

Crystal Growth

Crystal growth: mass transfer, heat transfer can not be

neglected; species entering structure, may also the rate

determining step

Relation between size and solubility: OstwaldFreundlich law, similar to Kelvin equation; small size (L

small) high solubility

surface nucleation mechanism birth and spread

screw dislocation mechanism

Impurity effect: often inhibit growth by adsorption on

specific site (surface), often change morphology

ln(X / X eq ) 2M / 3LRT

•Growth steps:

•Diffusion to surface; Adsorption; Desolvation;

(dehydration); Surface diffusion; Integration at kink site

•terminology: ledge, step and kink

F = surface energy

xL/ xeq = a

measure

of supersaturation

It shows small size, large solubility; for low surface energy,

size effect less significant (see Kelvin equation)

Che5700 陶瓷粉末處理

Growth Rates

Different mechanism, different equations to show

relation between growth rate and supersaturation: e.g.

Birth & Spread mechanism (2D nucleation model):

growth rate ~ (step height) x (step velocity) 2/3 x

(#critical nuclei formed/area-time) 1/3 G = A i 5/6

exp(-B/i)

General empirical equation: G = k n

Note: can be supersaturation with respect to bulk, or

to surface

Can be

classified as:

linear, parabolic,

and

exponential law

(growth rate

and

supersaturation)

Che5700 陶瓷粉末處理

More on Growth Rates

Growth rate may depend upon size, I.e. G = f(L)

Growth rate dispersion: due to different residence time,

or due to surface structure & perfection

Too fast growth rate, easy to trap mother liquid

(inclusion)

Heat production: interface temperature may affect

solubility near interface i.e. super-saturation, or

growth rate

In general: linear growth rate = mass transfer or

adsorption effect

parabolic rate = spiral steps

exponential rate = polynuclear surface control

(H / M )GC hi (Ti T )

Growth rate

proportional to

density of

defects (screw

dislocation)

Accumulation of supersaturation nucleation

supersaturation decrease nucleation stops growth

continue end

Summary on Particle

Formation

Reaction formation of some “species”

supersaturation (induction times)

Nucleation (home-, hetero- ..) (critical nucleus

size, nucleation rate)

growth (growth rate, crystal habit, …)

agglomeration

final particle size distribution and morphology

Veiled: 蓋面紗的, 遮蔽的

Crystal Habit

Equilibrium shape versus growth shape

Former: surface energy of each surface

Latter: relative growth of each surface,

depending on growth environment

Equilibrium shape: ( Wulff theorem: following

equation) large surface energy, small surface

area, I.e. easy to disappear

S / L (1) A(1) S / L (2) A(2) ... const.

equilibrium

shape;

Elimination of high

energy surface via

growth

Different morphology: obtained under different

supersaturation (AgBr);

From octahedron (only 111 surface), gradually change

to tetradecahedron (showing 100 surface), finally to

cubic (with only 100 surfaces)

Taken from TA

Ring, 1996; by

adsorbing

impurity species

to control

morphology

Che5700 陶瓷粉末處理

Ostwald Ripening

An aging process, often cause coarsening of

large particles at the expense of small ones

Driving force: difference between solubility

between sizes (thermodynamically-driven);

Gibbs-Thompson equation; also influenced by

mass transfer and growth kinetics

Cs (r ) C C [exp(a / r ) 1]

a 2VM /RT

(from Wikipedia)

* Ostwald ripening (often water-inoil system) vs flocculation (oil-inwater system)

* Diffusion is often rate controlling

process

Oil droplet in pastis

mixed with water grow

by Ostwald ripening

Time progress of supersaturation with time; critical nucleus

size for each supersaturation, the particle will grow up in size,

but particles formed later may be consumed due to Ostwald

ripening effect

Taken from 游佩青博士論

文稿 (成大資源工程系;

p.16; 2008)

* Maximum growth rate

size ~ 2 x average size

(where growth rate = zero)

a3 – ao3 = [6 D co

γM/(ρ2RT)] (t – to) where

a = average size, D =

diffusion coefficient; co =

solubility at interface;

γ=interfacial energy;

Digestive Ripening

Source: Langmuir, 2002, 18, 7515-7520

* Transform polydispersed particle to monodispersed Au

colloids after ageing in the presence of dispersive agents

* These monodispersed

colloids may be stable only at

high temperature, will form

ordered precipitate when

temperature cools down;

Taken from: New Journal of Chemistry, 35, 755-763, 2011

•Possible mechanism: dispersion molecule (surfactant) may

penetrate large colloids to adsorb on the surface and to

create small colloids;

• When the chain length of dispersion molecule decrease,

the attractive force between two particle will increase and

tend to form precipitate (self-assemble into 3D superlattice – look like reversible crystallization);