Revision - crystallisation

advertisement

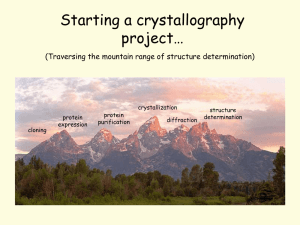

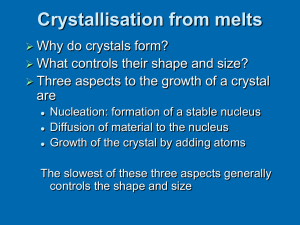

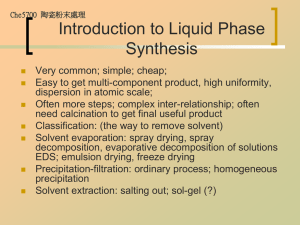

Crystallisation Gavin Duffy DIT, Kevin St. Learning Outcomes After this lecture you should be able to….. Describe crystal growth and nucleation Define the constituents of a solution and degrees of saturation Describe the solubility curve List three methods of achieving supersaturation/crystallisation Describe nucleation and crystal growth Give an example of crystallisation Analyse a crystallisation process in a pharmaceutical plant Explain how to crystallise by cooling Crystallisation - Introduction Crystallization refers to the formation of solid crystals from a homogeneous solution. It is a solid-liquid separation technique Used to produce Sodium chloride Sucrose from a beet solution Desalination of sea water Separating pharmaceutical product from solvents Fruit juices by freeze concentration Crystallisation requires much less energy than evaporation e.g. water, enthalpy of crystallisation is 334 kJ/kg and enthalpy of vaporisation is 2260 kJ/kg What is a crystal? A crystal is a solid form of substance (ice) Some crystals are very regularly shaped and can be classified into one of several shape categories such rhombic, cubic, hexagonal, tetragonal, orthorhombic, etc. With pharmaceuticals, crystals normally have very irregular shapes due to dendritic growth which is a spiky type appearance like a snowflake. It can be difficult to characterise the size of such a crystal. Crystals are grown to a particular size that is of optimum use to the manufacturer. Typical sizes in pharmaceutical industry are of the order of 50m. Crystallisation In general, crystallisation should be a straightforward procedure. The objective is to grow crystals of a particular size or crystal size distribution (CSD). If this is not successful, problems that can occur are: Inconsistency from batch to batch Difficult to stir and filter Crystals damaged in filtration/agitation Creation of polymorphs Difficult to dry Crystal Size Distribution - CSD A crystal Paracetamol crystals precipitated from acetone solution with compressed CO2 as antisolvent using the GAS technique Source http://www.ipe.ethz.ch/laboratories/spl/researc h/crystallization/project05 Accessed 131106 Solutions, Solubility and Solvent A solid substance (solute) is termed soluble if it can dissolve in a liquid (the solvent) to create a solution The solution is a homogenous mixture of two or more components Solubility is normally (but not always) a function of temperature Solubility can change if the composition of the solvent is changed (e.g. if another solvent is added) Solubility is usually measured as how many grams of solvent can be dissolved in 100 grams of solute Solubility curve – sucrose Ref: http://www.nzifst.org.nz/unitoperations/conteqseparation10.htm Solubility curve – NaCl Solubility Curve NaCl in H2O 100 90 Solubility g/100g H2O 80 70 60 50 40 30 20 10 0 0 10 20 30 40 50 60 Tem p Deg C 70 80 90 100 Saturation An Unsaturated or Undersaturated solution can dissolve more solute A saturated solution is one which contains as much solute as the solvent can hold A Supersaturated solution contains more dissolved solute than a saturated solution, i.e. more dissolved solute then can ordinarily be accommodated at that temperature Two forms of supersaturation Metastable – just beyond saturation Labile – very supersaturated Crystallisation is normally operated in the metastable region Concentration Kg solute/100kg solvent Solubility curve - Saturation diagram Supersaturated Or Labile Metastable Stable Temperature Stable zone – crystallisation not possible Metastable zone MSZ – crystallisation possible but not spontaneous Labile – crystallisation possible and spontaneous We need a supersaturated solution for crystallisation Concentration kg solute/100kg solvent Supersaturated Or Labile Metastable Stable Undersaturated Temperature 3 2 4 1 X 5 Metastable Stable Undersaturated Temperature Concentration kg solute/100kg solvent Concentration kg solute/100kg solvent Supersaturated Or Labile Supersaturated Or Labile 3 4 2 1 X Metastable Stable Undersaturated Temperature Concentration kg solute/100kg solvent Supersaturated Or Labile 3 2 4 1 X Metastable Stable Undersaturated Temperature Concentration kg solute/100kg solvent Determination of MSZW Cool 1 Heat 2 Dilute 3 4 Temperature MSZW is a function of kinetics (wider for faster cooling) Achieving Supersaturation Concentration Labile E D C B A Metastable Stable Temperature ABC - If A is cooled, spontaneous nucleation not possible until C is reached. No loss of solvent ADE – If solvent is removed, nucleation occurs at E Can combine cooling and evaporation Crystallisation Techniques In general crystallisation is achieved by Cooling a solution If supersaturation is a function of temperature Removal of the solvent by evaporation Where supersaturation is independent of temperature (e.g. common salt) Addition of another solvent to reduce solubility When solubility is high and above methods are not desirable, or in combination with above methods The new solvent is called the anti solvent and is chosen such that the solubility is less in this new solution than it was before Change in Concentration Concentration kg solute/100kg solvent Supersat, C = C – C* Nucleation C Crystal Growth C* Temperature Crystallisation Ref: http://www.cheresources.com/cryst.shtml Concentration kg solute/100kg solvent Activity B A C D Temperature Explain what is happening in each stage from A to D in the above crystallisation Supersaturation, C Supersaturation is the driving force for Nucleation Crystal Growth Creation and control of supersaturation is the key to successful crystallisation High C High Crystal Growth + High Nucleation High nucleation means a lot of fines (filtration problems) High crystal growth means inclusion of impurities C is usually maintained at a low level in the pharmaceutical industry so the right CSD is achieved Activity – How would you crystallise? Have a look at the solubility curves provided List the three techniques for achieving supersaturation Which would you use and why? Nucleation Crystallisation starts with Nucleation There are two types of nucleation – Primary and Secondary Primary relates to the birth of the crystal, where a few tens of molecules come together to start some form of ordered structure Secondary nucleation can only happen if there are some crystals present already. It can occur at a lower level of supersaturation than primary nucleation. Often, industrial crystallisers jump straight to secondary nucleation by ‘seeding’ the crystalliser with crystals prepared earlier Primary Nucleation The birth of a new crystal is complex and involves the clustering of a few tens of molecules held together by intermolecular forces Homogeneous – small amounts of the new phase are formed without any help from outside Heterogeneous – nucleation is assisted by suspended particles of a foreign substance or by solid objects such as the wall of the container or a rod immersed in the solution – these objects catalyse the process of nucleation so it occurs at lower levels of supersaturation Homogenous conditions are difficult to create so heterogeneous nucleation is more normal in industrial crystallisation (if it is not seeded) Primary Nucleation Nucleation rate Heterogeneous Homogeneous Supersaturation Secondary Nucleation Secondary nucleation is an alternative path to primary nucleation and occurs when seed crystals are added Nucleation occurs at a lower supersaturation than primary when crystals are already present Secondary nucleation is due to: Contact nucleation – crystals are created by impact with agitator or vessel wall. Nuclei are created by striking a crystal – the number created is related to the supersaturation and the energy of impact. Can occur at low supersaturation. Shear nucleation – shear stresses in the boundary layer of fluid flow create new crystals/nulcei. Embryos are created and swept away that would have been incorporated into an existing crystal Very important in industrial crystallisers as this is the main type of crystal growth used Difficult to predict or model nucleation rates Supersaturation and Crystal Growth For low supersaturation primary nucleation is not widespread. Secondary nucleation on existing crystals is more likely. Result is small numbers of large crystals For high supersaturation primary nucleation is widespread. This results in many crystals of small size. Slow cooling with low supersaturation creates large crystals Fast cooling from high supersaturation creates small crystals Agitation reduces crystal size by creating more dispersed nucleation Rate of cooling can affect purity of product - see handout on slow cooling v rapid cooling Seeding The type or quality of seed used can influence the crystallisation process Good seed results in a good crystallisation, i.e. a particle size distribution that does not include fines Bad seed can increase the amount of fines produced Good and Bad can be defined by the seed crystal size Source of seed can be Material left from the last batch (no tight control on particle size) Specially prepared material or material from a good batch (tight particle size distribution) When to Seed? Seed can be added dry to the crystalliser Allow time for dispersion throughout the crystalliser – this can take several hours Never seed to the right of the solubility curve – the solution is not yet ready Never seed to the left of the solubility curve – nucleation is already happening Seed half way between the two No. of Particles Seeded V Unseeded Unseeded Seeded Time With unseeded nucleation does not occur till later when supersaturation is higher. High rate of nucleation follows. Seeding – advantages, disadvantages Advantages include Point of nucleation from batch to batch is repeatable Reduces the number of fines Improves predictability of scale up Can prevent polymorphism Disadvantages Experience has shown that not any seed will do, good quality seed is needed Extra addition point on vessel or hand hole is usually opened to manually add seed which could create health and safety issues Crystal Growth Once nucleation has occurred crystal growth can happen The objective of crystallisation is to produce the required crystal size distribution (CSD) The actual CSD required depends on the process Crystal growth rate has proved difficult to model and empirical relationships developed from laboratory tests are generally used Two steps to crystal growth Diffusion of solute from bulk solution to the crystal surface Deposition of solute and integration into crystal lattice CSD Counts The following CSD is very common. 50 m crystals are the desired outcome in this crystallisation. However, some fines are created also. Fines problem 50m Crystal Size Impurities and Crystal Growth Impurities can prevent crystal growth If concentration of impurities is high enough crystals will not grow Should not be an issue in the pharmaceutical industry For example, the production of non crystalline sweets such as lollipops (sugar crystals give an unwanted grainy texture) Addition of acid breaks sucrose into fructose and glucose This makes it difficult for sucrose crystals to form because the impurities damage the structure Addition of other sugars creates the same result