Centrifugation: Theory, Equipment & Calculations

advertisement

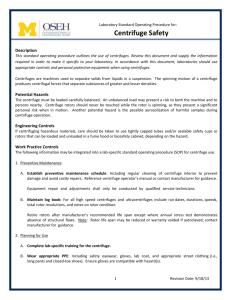

CENTRIFUGE CENTRIFUGATION A process used to separate or concentrate materials suspended in a liquid medium. Centrifugation separates on the basis of the particle size and density difference between the liquid and solid phases. THEORY OF CENTRIFUGATION the effect of gravity on particles (including macromolecules) in suspension. Two particles of different masses will settle in a tube at different rates in response to gravity. Centrifugal force is used to increase this settling rate in an instrument called a centrifuge. Centrifuges are devices used in a variety of scientific and technical applications The centrifugal force generated is proportional to the rotation rate of the rotor (in rpm) and the distance between the rotor center and the centrifuge tube. CENTRIFUGE SEPARATION PROCESS Settling: acceleration from gravity (Fg) Centrifuge: acceleration from centrifugal force (Fc) circular motion and acceleration occurred from centrifugal force ac r 2 ac = acceleration from centrifugal force (m/s2) r = radial distance (m) ω = angular velocity (rad/s) CENTRIFUGAL FORCE (FC) The centrifugal force, Fc acting on an object of mass m, rotating in a circular path of radius R, at an angular velocity of ω is : Fc mR 2 (1) and 2N N 60 30 (2) where N = rotational speed (rpm) ω= an angular velocity (rad s-1) G FORCE (GRAVITIES OR G’S) The steady-state velocity of particles moving in a streamline flow under the action of an accelerating force from vt g ( s l ) Dp2 18 r ( s l ) D 2 vt 2 p 18 Where vt=terminal velicity of partical; ρs and ρl = density of solid and liquid ; r = distance of the particle from center of rotation;µ = viscosity of liquid. CENTRIFUGATION TIME Time taken by the particle to move though the liquid layer is called residence time (tr). dr Vt dt ( p )D r vt 18 2 2 p dr D r ( p ) dt 18 2 p 2 D ( p ) 1 dt r r dr 18 0 i ro 2 2 p t ro D ( p ) tr ln 18 ri 2 p 2 ro 18 ln ri tr 1 2 2 D p ( p ) CALCULATION OF FLOW RATE FOR CONTINUOUS CENTRIFUGE flow rate (Q) (ro2 ri 2 )b V Q ro tr 18 ln ri 2 2 D p ( p ) Q (ro2 ri 2 )b D p2 2 ( p ) ro 18 ln ri ri = inside radius (m) ro = outside radius (m) b = height of centrifuge(m) µ = viscosity (Pa.s) ω = an angular velocity (rad s-1) ρp = density of solid (kg/m3) ρ = density of liquid (kg/m3) Dp= diameter of particle(m) LIQUID SEPARATION Figure 1 Liquid centrifuge (a) Pressure difference Consider a thin differential cylinder, of thickness dr and height b as shown in Fig. 1(a): the differential centrifugal force across the thickness dr is given by equation (1): dFc = (dm)r2 where dFc is the differential force across the cylinder wall, dm is the mass of the differential cylinder, is the angular velocity of the cylinder and r is the radius of the cylinder. dm = 2πρrbdr where is the density of the liquid and b is the height of the cylinder. The area over which the force dFc acts is 2πrb , so that: dFc /2πrb = dP =ρ 2rdr where dP is the differential pressure across the wall of the differential cylinder. To find the differential pressure in a centrifuge, between radius r1 and r2, the equation for dP can be integrated, letting the pressure at radius r1 be P1 and that at r2 be P2, and so P2 - P1 = ρω2 (r22 - r12)/2 (3) Equation (3) shows the radial variation in pressure across the centrifuge. Figure 1 Liquid centrifuge (b)neutral zone ρAω2 (rn2 - r12)/2 = ρB ω2(rn2– r22)/2 rn2 = (ρAr12 - ρBr22) / (ρA - ρB) (4) where ρA is the density of the heavier liquid ρB is the density of the lighter liquid Equation (4) shows that as the discharge radius for the heavier liquid is made smaller, then the radius of the neutral zone must also decrease CENTRIFUGE EQUIPMENT LIQUID/LIQUID SEPARATION CENTRIFUGES FIG. 2 Liquid centrifuges: (a) conical bowl In liquid/liquid separation centrifuges, conical plates are arranged as illustrated in Fig. 2(a) and these give smoother flow and better separation. Whereas liquid phases can easily be removed from a centrifuge, solids present much more of a problem. LIQUID/SOLID SEPARATION CENTRIFUGES FIG. 3 Liquid/solid centrifuges (a) telescoping bowl, (b) horizontal bowl, scroll discharge LIQUID/SOLID SEPARATION CENTRIFUGES (c) FIG. 3 Liquid/solid centrifuges (c) nozzle One method of handling solids from continuous feed is to employ telescoping action in the bowl, sections of the bowl moving over one another and conveying the solids that have accumulated towards the outlet, as illustrated in Fig. 3(a). The horizontal bowl with scroll discharge, centrifuge, as illustrated in Fig.3(b) can discharge continuously. In this machine, the horizontal collection scroll (or screw) rotates inside the conical-ended bowl of the machine and conveys the solids with it, whilst the liquid discharges over an overflow towards the centre of the machine and at the opposite end to the solid discharge. Another method of handling solids is to provide nozzles on the circumference of the centrifuge bowl as illustrated in Fig. 3(c). These nozzles may be opened at intervals to discharge accumulated solids together with some of the heavy liquid. EXAMPLE 1 Find centrifugation time tr of a particle d=1mm. In a centrifuge Given N 995RPM Ri 8.110 Pa.s 4 P 1100kg / m 3 f 1000kg / m 3 Ri 0.20m. Ro 0.25m. Ro Find ω 2N 60 2 995 60 104.20rad / s Find time 18 ln(ro / ri ) tr 2 2 d p f 4 18 8.110 ln(0.25 / 0.20) tr 2 2 0.001 104.20 1100 1000 3 t r 3.2510 sec tr of particle d=1mm. in centrifuge≥3.25x10-3sec EXAMPLE2 A bowl centrifuge is used to break an oil-inwater emulsion. Determine the radius of the neutral zone in order to position the feed pipe correctly. (Assume that the density of the continuous phase is 1000 kg/m3 and the density of the oil is 870 kg/m3. the outlet radius from the centrifuge are 3 cm and 4.5 cm). Solution 1000(0.045) 870(0.03) rn 1000 870 2.025 0.783 rn 130 rn 0.098m 2 2 2 EXAMPLE 3 Beer with a specific gravity of 1.042 and a viscosity of 1.04x10-3 N s/m2 contains 1.5% solids which have a density of 1160kg/m3. It is clarified at a rate of 240 l/h in a bowl centrifuge which has and operating volume of 0.09 m3 and a speed of 10000 rev/min. The bowl has a diameter of 5.5 cm and is fitted with a 4 cm outlet. Calculate the effect on feed rate of an increase in bowl speed to 15000 rev/min and the minimum particle size that can be removed at the higher speed. Solution Initial flow rate V (2N1 / 60) D p f 2 Q1 2 18 ln(ro / ri ) new flow rate Q2 V (2N 2 / 60) 2 D 2 p f 18 ln(ro / ri ) As all conditions except the bowl speed remain the same, Q2 (2N 2 / 60) 2 Q1 (2N1 / 60) 2 Q2 (2 3.142 15000/ 60) 2 (240/ 3600) (2 3.142 10000/ 60) 2 Therefore, Q2 = 0.15 l/s TO FIND THE MINIMUM PARTICLE SIZE Q2 [18 ln(ro / ri )] D (2N 2 / 60) 2 ( p f )V 2 0.15[181.40103 ln(0.0275/ 0.02)] (2 3.14215000/ 60) 2 (1160 1042)0.09 3 1.2010 D 6.8m 7 2.6210