Diapositiva 1

advertisement

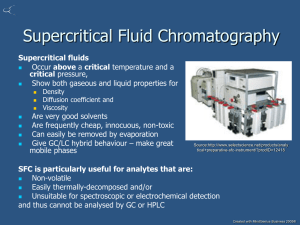

Ciencia y Tecnología del Color Seminario 2009 Viability of Dyeing of Natural and Synthetic Fibers with Nanopigments in Supercritical CO2 Bàrbara Micó, Verónica Marchante, Francisco Martínez-Verdú, Eduardo Gilabert ÍNDEX Introduction Supercritical CO2 Dyeing in supercritical CO2 Nanopigments and nanoclays Objectives State of the art Colorant selection Fibres Process variables Challenges Solutions / Future perspectives Advantages of using Nanopigments References / Acknowledgements INTRODUCTION Supercritical CO2 : Solvent Properties Low cost Non-Toxic Density: liquid Viscosity: Gas Recycling up to 90% Inert Non-explosive Low critical point Pressure: 73.858 ± 0.005 bar Temperature: 31.05 ± 0.05 ºC DYEING IN SUPERCRITICAL CARBON DIOXIDE ADVANTAGES No waste water (problem in textile industry) No require additives No final drying Recycling Solvent Colorants Environmental friendly DRAWBACKS Investment Solve colorants Time of process NANOPIGMETS NANONATERIALS: since 90’s Hybrid materials consisting of organic dyes and layered silicate nanoparticles Nanoclay: particle size < 20nm Ionic-exchange reaction: Colorant + Nanoclay (H+) Nanoclays: Smectite group Montmollonite: laminar Sepiolite: acicular Scheme of nanopigments’ synthesis at laboratory Stage 1 Nanoclay H2O deionized Sieving Dispersion + Stage 2 Colorant solution Ionic Exchange Washing and Filtering Drying APLICATIONS: - Coloration of Plastics - Printing Inks - Functional materials Schematic representation of clay sheet, dye molecule (methylene blue) and blue Nanopigment. e arcilla 3 3 CH metileno e arcilla S CH CH 3 3 N 3 CH 3 CH 3 CH CH S CH N 3 CH 3 S CH N 3 N 3 CH CH CH 3 3 S H3 CH N C 3 CH 3 S CH N C S CH 3 N N 3 N N 3 C H3 N 3 CH N N CH 3 CH N N CH 3 CH S 3 S 3 CH 3S CH N 3 CH S CH3 CH N 3 CH 3 CH 3 3 CH CH H3 3 CH N N CH N N S CH3 3 CH S 3 N 3 CH H3 3 CH N N CH 3 N 3 CH 3 CH N N S CH3 3 CH N N 3 CH N N C S C H3 3 CH CH 3 3 N N 3 CH N N C 3 N 3 CH S H3 CH N N 3 CH N N 3 CH CH N N 3 N 3 CH N CH 3 N CH 3 S N OBJECTIVES: PROJECT AITEX-AINIA-UA 2. SELECTION /MATERIAL DEVELOPMENT 2.2. COLORANTS 2.3. ANTIBACTERIAL AGENTS 3. DISSOLUTION OF MATERIALS IN SC CO2 4. POLYMER IMPREGNATION IN SC-CO2 6. REENGINIEERING 7. VIABILITY / ECONOMIC 5. CHARACTERIZE TREATED MATERIAL WITH SC-CO2 8. RESULTS AND DOFUSION 1.STATE OF THE ART 2.1. POLIMERS STATE OF THE ART Colorants that can be solved in scCO2 Textile dyes classification: Directs Reactive Acids/Basics Sulphur NOT DISSOLVED IN SC- CO2 Vat Mordant Disperse Pigments DISSOLVED IN SC-CO2 COLORANT SELECTION DISPERSE DYES Azoic [ N N ] The most important disperse dyes Cheaper and easy manufacture From non polar fibers Anthraquinone It’s more soluble [1] More expensive MORE SOLUBILITY COLORANT: SELECTION REACTIVE DISPERSE DYES [2] (mono-di-)chlorotriazine (mono-di-)-fluorotriazine Dyeing of natural fibers Protein or synthetic fibers REACTIVE GROUPS CHANGE THE COLORANT’S SOLUBILITY N R N Cl N Colorant Colorante Dyeing cotton Using different co-solvents Methanol improves the solubility + Fibre Fibra-OH Fibre O Fibra N R N N Colorant Colorante COLORANT SELECTION REACTIVE DYES Vinylsulphone : Improve fixations [3] Are suitable for dyeing textiles containing polyester, nylon, silk or wool. Fixations between 70 – 90% Solubility : [4] -Decrease: OH, NH2,COOR’ -Increase: HX NO2 [X=F,Cl,Br,..] PROCESS VARIABLES Dyeing steps Transport of dye to the fibres: SOLUBILITY Works: different cosolvents Acetonitrile Methanol Water IMPROVE THE REACTIVE RESULTS GROUPS Acetone Reaction of the dye with the textile: AFFINITY DIFFUSSION of dye into the fibres: D coefficient. PARTICLE SIZE EQUIPMENTS Gas cylinder Carbon dioxide pump Pressure gauge Stop valves Pump head cooler Dyeing vessel Stirrer Cosolvent pump Cosolvent reservoir Back pressure regulator Dyeing beam Heating jacket EQUIPMENTS: AINIA PILOT PLANT Planta FSC500 Planta SFF-58_60 Planta PFS20 FIBRES PET the most studied Changes in the structure of polymers: Plastics: >Tg Size stability Natural fibres [5] Pre-treatments: Hydrophobic and nonpolar Polyurethane DMDHEU Solvents: Alcohol and water CHALLENGES We only can use non polar colorants in scCO2: These kind of colorant haven’t affinity of natural fibres. There are a lot of variables in the process: Solubility can change with: Colorants (Reactive group, Particle size…) Pressure Temperature Substrates: Natural or synthetic fibers The time of process is too long: 4h SOLUTIONS / FUTURE PERSPECTIVES Pre-treated fibres: PET: with UV, N,N-dimethylacrylamide CO: DMDHEU, PUR, acetone… Changes in structure of colorants [6] Novel reactive disperse dyes has been synthesized. Control the solubility and dye process. Equations to predict the solubility. NANOPIGMENTS ADVANTAGES OF NANOPIGMENTS Nanopigments are a viable and environmentalfriendly alternative to traditional pigments because of their easy synthesis and conventional processing. Increase the color gamut: We can use a lot of conventional organic dyes. Increase the resistance of colors: UV, O2, Temperature Improve substrate properties: stability, strength, permeability… REFERENCES [1] S. N. Joung et all. “Solubility of Disperse Anthraquinone and Azo Dyes in Supercritical Carbon Dioxide at 313.15 to 393.15 K and from 10 to 25 MPa” J. Chem. Eng. 43, 9-12. 1998 [2] M.V. Fernandez et all “A significant approach to dye cotton in supercritical carbon dioxide with fluorotriazine reactive dyes” J. of Supercritical Fluids 40 477–484. 2007 [3] M. van der Kraan et all. “Dyeing of natural and synthetic textiles in supercritical carbon dioxide with disperse reactive dyes” J. of Supercritical Fluids 40 470–476. 2007 [4] Gerardo A. Montero et all. “Supercritical Fluid Technology in Textile Processing: An Overview” Ind. Eng. Chem. Res., 39, 4806-4812. 2000 [5] P. L. Beltrame, et all.“Dyeing of Cotton in Supercritical Carbon Dioxide”. Dyes and Pigments, 39, 335-340. 1998 [6] Andreas Schmidt, Elke Bach and Eckhard Schollmeyer. “Supercritical fluid dyeing of cotton modified with 2,4,6-trichloro-1,3,5-triazine”. Color. Technol., 119. 2003 Acknowledgements This work is supported by Ministry of Science and Innovation (MICINN) with the project “Aplicación de la tecnología de fluidos supercríticos en la impregnación de sustratos poliméricos” ref.: CIT20000-2009-2.