Transcritical ORCs

advertisement

ORCNext – WP4 Development of supercritical technologies Catternan Tom www.orcnext.be 1 ORCNext – WP4 Development of supercritical technologies Transcritical ORCs – Literature review www.orcnext.be 2 Transcritical ORCs Best efficiency highest when temperature • Better thermal and matching power drivingoutput force LMTD↓ UA↑ profile of HS and WF match lower exergy destruction (Larjola et al.). www.orcnext.be 3 Selection of working fluids • Wide range of applications and ranges no consensus for best working fluid. Screening criteria Cycle criteria Safety (ASHRAE 34) Thermodynamic PI Environmental (GWP, ODP, ATL) Heat exchanger PI Stability working fluid Cost PI Compatibility with materials Thermophysical properties Availability and cost www.orcnext.be 4 Selection of working fluids Physical data Name Type Tcrit (°C) HFC-23 Wet 26,14 R-747 (CO2) Wet 31,10 HFC-125 Wet 66,02 HFC-410A 70,20 PFC-218 Isentropic 71,89 HFC-143a Wet 72,73 HFC-32 Wet 78,11 HFC-407C 86,79 HFC-134a Isentropic 101,03 HFC-227ea Dry 101,74 PFC-3-1-10 Dry 113,18 HFC-152a Wet 113,50 PFC-C318 Dry 115,20 HFC-236ea Dry 139,22 PFC-4-1-12 Dry 147,41 HFC-245fa Isentropic 154,05 HFC-245ca Dry 174,42 Molecular pcrit (bar) weight (g/mol) 48,30 70,01 73,80 44,01 36,20 120,02 47,90 72,58 26,80 188,02 37,64 84,04 57,83 52,02 45,97 86,20 40,56 102,03 29,29 170,03 23,20 238,03 44,95 66,05 27,78 200,03 34,12 152,04 20,50 288,03 36,40 134,05 39,25 134,05 Safety data ASHRAE 34 safety group A1 A1 A1 A1 A1 A2 A2 A1 A1 A1 A2 A1 B1 A1 Environmental data GWP ATL (yr) ODP (100 yr) 270 0 14800 >50 0 1 29 0 3500 16,95 0 2088 2600 0 8830 52 0 4470 4,9 0 550 15657 0 1800 14 0 1430 34,2 0 3220 2600 0 8600 1,4 0 124 3200 0 10250 10,7 0 1370 4100 0 9160 7,6 0 900 6,2 0 693 www.orcnext.be 5 Heat exchanger design Influence ORC parameters on HX design (Schuster and Karellas, 2012) • R134a, R227ea and R245fa • Jackson correlation (1979): Water and CO2 • HTC decreases with increasing supercritical pressure and temperature HX area increases • Relatively unknown heat transfer mechanisms around C.P. need further investigation www.orcnext.be 6 ORCNext – WP4 Development of supercritical technologies Forced convective heat transfer at supercritical pressures Literature review www.orcnext.be 7 Supercritical state • Critical point ‘c’ • Supercritical state • For T>Tcrit Continuous transition from liquid-like fluid to gas-like fluid (no phase change) www.orcnext.be 8 Thermophysical properties • (cp, m, r, l, Pr…)=f(T) • Pseudo-critical temperature Tpc= f(p) www.orcnext.be 9 Thermophysical properties www.orcnext.be 10 Literature overview • Experimental – H2O, CO2, nitrogen, hydrogen, helium, ethane, R22 – Uniform cross section • Circular • Recently: triangular and square – Uniform heat flux electrically forced Tw – Different experimental results • Numerical – Only recent www.orcnext.be 11 General characteristics Heat transfer enhancement Maximum HTC (1) Theory (∆) Experimental: 𝑚 = 140±4.4 kg/h; q = 1.44 W/cm² • 𝑇𝐵𝑢𝑙𝑘 ≤ 𝑇𝑝𝑐 ≤ 𝑇𝑤𝑎𝑙𝑙 • 𝑞↓ • 𝑚↑ • Due to variation of thermophysical properties (2) Theory (x) Experimental: 𝑚 = 140±3.1 kg/h; q = 2.73 W/cm² (3) Theory (○) Experimental: 𝑚 = 280±5.6 kg/h; q = 3.32 W/cm² (4 Theory (●) Experimental: 𝑚 = 280±7.8 kg/h; q = 5.20 W/cm² Variation of the heat transfer coefficient with bulk temperature for forced convection in a heated pipe for carbon dioxide of 78.5bar flowing upwards in a 1.0 diameter vertical pipe. www.orcnext.be 12 General characteristics Heat transfer deterioration • Comparison upward and downward flow – Downward no unusual behaviour – Upward deterioration Upward flow 1 2 3 4 5 6 7 8 𝒎 𝑨 (𝒈𝒎 𝒔 𝒄𝒎²) 382 382 400 375 400 400 393 381 𝒒 (𝑾/𝒄𝒎𝟐 ) 27 37 45 52 27 36 43 50 Downward flow Flow direction Vertical upward Vertical upward Vertical upward Vertical upward Vertical downward Vertical downward Vertical downward Vertical downward Wall and bulk temperature as a function of the distance along a vertical heated 1.6 cm diameter pipe for water at 245 bar (1.11 pcrit). www.orcnext.be 13 General characteristics Heat transfer deterioration • Comparison upward, downward and horizontal flow (1) Horizontal pipe – upper surface (2) Horizontal pipe – lower surface (3) Vertical pipe – upward flow (4) Bulk fluid temperature Temperature distribution as a function of local bulk enthalpy along heated vertical and horizontal pipes (1.6 cm diameter) for water at 245 bar (= 1.11 pcrit): 𝒎 𝑨 = 𝟔𝟎 𝒈𝒎 𝒔 𝒄𝒎² and 𝒒 = 𝟓𝟐 𝑾/𝒄𝒎𝟐 www.orcnext.be 14 Influence of parameters • Heat flux 𝑞 Left: Ratio of the experimental heat transfer coefficient to the value calculated via the Dittus-Boelter equation;. Right: Wall temperature behaviour for low and high heat fluxes. www.orcnext.be 15 Influence of parameters • Heat flux 𝑞 • Mass flow 𝑚 Generalized curves for water at 250bar (Lokshin et al.) www.orcnext.be 16 Influence of parameters • Heat flux 𝑞 • Mass flow 𝑚 • Flow direction Comparison of heat transfer between an upward and downward flow for CO2 by Jackson and EvansLutterodt www.orcnext.be 17 Influence of parameters • • • • Heat flux 𝑞 Mass flow 𝑚 Flow direction Pipe diameter Effect of tube diameter on heat transfer coefficient (Cheng X. et al.) www.orcnext.be 18 Correlations • • • • • • • • • • • • • • • • • • Bringer and Smith (1957) Miropolsky and Shitsman (1959, 1963) Petukhov, Krasnoshchekov and Protopopov (1959, 1961, 1979) Domin (1963) Bishop (1962, 1965) Kutateladze and Leontiev (1964) Swenson (1965) Touba and McFadden (1966) Kondrat’ev (1969) Ornatsky et al. (1970) Yamagata (1972) Yaskin et al. (1977) Jackson (1979) Yeroshenko and Yaskin (1981) Watts (1982) Bogachev et al. (1983) Griem (1995, 1999) Heat transfer coefficient for supercritical water according to different correlations (Cheng X. et al.) … www.orcnext.be 19 ORCNext – WP4 Development of supercritical technologies Goals and planning for the next 6 months www.orcnext.be 20 Transcritical ORCs • Finish literature study (± 10 more papers to read) • Model sub – and transcritical cycle (together with WP1) – Choose parameter range – Compare both cycles using the Performance Indicators for several working fluids – Check influence of the variable parameters on the objective functions sensitivity – Make a list of 3 working fluids, which will be used in the experimental setup www.orcnext.be 21 Supercritical forced convection heat transfer • Investigate thermophysical properties under supercritical conditions of the selected working fluids (via REFPROP or EES) • Finish literature study – Deteriorated and improved heat transfer regimes – Onset deterioration – Correlations • Fundamental understanding heat transfer and occurring flow Test setup have to be built: – Prepare setup – Choose materials – Order www.orcnext.be 22 Thank you for your attention. www.orcnext.be 23

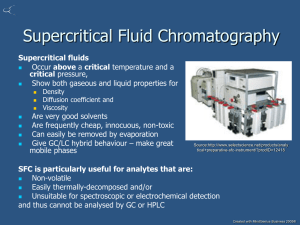

![Heat transfer mechanisms Nucleation at high subcritical pressures [1]](http://s3.studylib.net/store/data/006613018_1-484ac98340bdf87d83d3defecfde6c98-300x300.png)