La teinture en vetement

advertisement

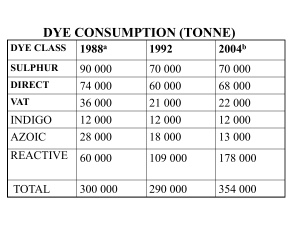

Garment Wet Processing Presented by Aart Geurtsen Wet processing of Cotton Fabric Current estimate of world cotton production is about 25 millions tons per year This means 112 millions bales of 480 lb/heac. China is the largest producer in the world. Top 5 World Producers of Cotton (Year 2011) 9000 33500 10000 China 33500 USA 27000 India 15674 Pakistan 10000 15674 27000 Brazil 9000 X 1000 X 480 lb. bales Source: United States Department of Agriculture * Bangladesh = 66 The properties of the cotton fiber varies from the conditions and the area where cotton is produced. Preparation of the Cotton fabric • Scour • Pre-Bleach • Prepare for dyeing Option 1 • The scouring removes all dirts & chemicals present on the fabric, which could interfer with the pretreatment (cationisation) of the fabric. • It helps to make the fabric more absorbant allowing, in the same time, a better diffusion of the chemicals used to pretreat or cationise the fibre. Scour 0.5% Triscour JET conc 1.0% Soda ash 2.0% Caustic Soda 50% 96°C for 30 minutes Rinse et neutralize Option 2 142,150 Helps remove the oxidized oils and the yellow pigment in the cotton . This bleaching will help to obtain pale shades and more brilliant colors. Pre-Bleach 0.5% 0.1% 2% 4% Triscour JET conc (wetting + detergent) Tristabilizer Jet-5 ( H2O2 Stabilizer) Caustic Soda 50% (NaOH) Peroxide 50% (H2O2) (Temperature of 96°C for approximately 30 minutes) This operation of bleaching will be followed by a neutralization with acetic acid, as well as the neutralization of peroxide by a catalase enzyme, such as Triminox GH. Note: For a white, we will add an optical brightener Tricoblanc BA 80% liquid. 0.8% - 1.0 % owg. Prepare for dyeing Jersey or Fleece Applying lubricant After pre-bleach, the cotton will need an application of a polyethylene emultion and/or fatty acid in order to facilitate the operations of napping or cut and sew. This operation is usually made by nip padder with: 30 gr. liter of Tricosoft MSG This softener-lubricant is very easy to remove with a light Scouring, before carrying out the dyeing. Dyeing process with pigments • • • • Scouring Cationic pretreatment Dyeing Softener application First Step prior to Garment Dying In some cases the presence of hand modifiers, could make the fibre practically hydrophobic Good scouring is a must 0.5 gr./l. Triscour JET conc 1.0 gr./l. Sodium Carbonate 2.0 gr./l. Caustic Soda (optional) Run 60 °C for 30 min. (Optional 96°C for 30 minutes) Scouring Process 60°C 1% Triwhite JET 5 1% Soda ash 30°C Dyeing 5` 10` 10` 5` Ring dye process Why fixing the dyes at the surface of the fiber? All conventional methods of dyeing suggest to penetrate completely the fiber. In the ring dye process, we apply the dyes right onto the surface of the fiber to allow subsequent wash down. The mechanical action in the machine will contribute to give an old or worn out effect to the garment, which will appear to have been washed many times in a laundering machine. Effect of Abrasion Fiber Cationic Pigment Effect of abrasion Pigment Dyeing (Ionic Bond) Pigments Pigment Cationic Agent Cationic Agent Cotton Fiber Cationisation agent of positive load adheres to the surface of fibre in a first operation named “pretreat” and then the dye of negative charge adheres to the surface of the cationic agent in the second operation, the dyeing. Cationic Pretreatment Process Dosing Texafix BR Acetic Acid 60°C Triscour Jet conc. Tricellulase BPN 30°C Dyeing 2` 5` 20` 15` 5` 10` 5` Pigment Dyeing Process Sample check Acetic Acid option addition Texalev JL 60°C Pigment + Tri Binder AC-M-2240N by dosing 1. Rinse 20 ° C 2. Rinse 40 ° C 30°C 2` 15` 10` 20` 20` 10` 5` Pigments • • • • vs Pigments Direct Reactive Sulphur others types of dyeing Ionic bonds Forces of Van der Waalls Covalent bonds Fixed by insolubilisation Direct Dyes The direct dye being of negative charge just like cotton, makes them repulse. It is necessary in the case of the direct dyeings to use an ELECTROLYTE which will separate in positive and negative ions in the bath from dyeing. •The positive ions will move towards fibre to fill the negative charge of cotton. •The negative ions will make competition with the dye of negative charge and will make it to go up on fibre by force of repulsion. Salt will help the dye to get on fibre, the temperature will help with the swelling of fibre, and a neutral or slightly alkaline pH to help with the solubilizing groupings. Classes of Direct Dyes Class A: These dyes have a great capacity of migration even when electorlytes are involved. It can be unequal at the beginning, but will level out when a temperature of 205°F is reached Class B: These dyes have less migration and use less électrolytes. The levelness of these dyes can be controlled by by salt addition. It is very important that the dye is also applied from the very start. Class C: These dyes have a very poor capacity of migration and they are very sensitive to the electrolytes. In certain cases these dyes exhaust quickly without addition of salt. Note: When temperature decreases the affinity of the dye for fibre also decreases, but it increases its capacity of migration towards the other sites, thus improving levelness. Procedure for Direct Dyes Dose Salt Trilube XTC 96°C Soda Dyes Tricofix NZ Acide 50°C 30°C Precautions in production The dissolution of the direct dye is done at the temperature of the cycle of dyeing, This means 96°C except for the black 22 were we add the dye to the warm water already in agitation to avoid agglomeration of dye. Dosing(proportioning) of the dye is done by the return water in the addition tank . Reactive Dyes The dye is not attracted towards fibre, we have to use an electrolyte to push the dye towards fibre The reactive grouping of the dye bonds with the alcohols group of the cellulose which is present as an atom and will form a very solid covalent bond. The reaction between fibre and the dye will release acide HCl, This is why it will be necessary to compensate with alkali to keep a pH of ±11. Deep shade generate more HCL and consequently requires more alkali to obtain our pH. Refer to table of Alkali for good fixation Reactivity of the dyes Trichloro pyrimidine Drimarene XZ Monochloro trazine Cibacron E, Procion H/HE, Triactive HE Vinyl Sulphone Monochlorotrazine Triactive DF Vinyl Sulphone Triactive & Remazol Monofluoro triazine & Vinyl sulphone Cibacron C Dichloro quinoxaline Levafix E Monofluorotriazine Cibacron F Difluoro monochloro pyrimidine Levafix E/A Drimarene K/R Dichloro triazine Procion MX Low. Reactivity High Precautions in production The dissolution of the reactive dye is done at the temperature of the cycle of dyeing, Exemple: 60°C for Triactive DF, or 80°C for Triactive HE. Add the dye powder to water with agitation, to not create agglomeration of dye Dosing (proportional) of the dye and Alkali should be done with fresh water and not by the return water in the addition tank • • • Add the dye in 30 minutes or more, allowing good diffusion in fibre before adding alkali. Ensure to maintain a ph of ± 11 after the alkali addition to assure good fixation of the dyes. 6 Options Option 1. Triactive DF 60 C Option 2. Triactive Hot type 80C Run for45 minutes 80C 10’ 6 30min Run for45 minutes 60C 10’ 1 2 3 4 45’ 5 30 min Tex Alkali ASL Soaping 30°C 20’ Dyes LegendAGD, 2. TriminoxProcess 1. Graph Tridefoam GH, 3. Salt, Cycle 4. Trilube BW, Products Addition 5. Triactive dyes 6. Dosing Tex Alkali ASL Drop Bath Soaping is performed at 96 C with Triquest HON for 10 minutes Optional Step Soaping of the Reactive dyes In reactive dyeing, usually the dye will be fixed on fibre, but there will be also hydrolized dyes on the surface of fibre. Indeed certain bonds are done with fibre, but unfortunately some are also done with water. For this reason it will be necessary after fixing, to rinse fabric very well and make a soaping with Triquest HON wich is a very good dispersing and anti-redeposition agent. In this way the remaining electrolyte will be removed, thus reducing the affinity of the dye for fibre, thus helping the washing off. The dye not fixed and hydrolized will be removed in its turn and we will obtain better rubbing and washing fastness . Stripping of the Reactive dyes Option #1 4 gr./l. Caustic soda 50% heat to 80°C 2 gr./l. Tritex TD (Thioreadioxide) heat to 100°C Run for 30 minutes rimse and neutralize Option #2 1 gr./l. Soda Ash pH 10 - 11 20 gr./l. Sodium Hypochlorite (NaOCl) heat to 50°C run for 20 minutes Rinse Neutralize with 2 gr./l. Sodium Métabisulphite 50°C for 15 minutes Dyeing with Sulphur Dyes (For Deep Black Shades) These dyes are usually insoluble and require to be solubilized or reduced to be able to penetrate fibre. They will be finally rendered insoluble again to remain permanently. Example formulation of the bath reductor for 18 % of dyeing 1.0gr./l. 1.0gr./l. 0.5gr./l. 30.0 gr./l. 12.0 gr./l. 11.0 gr./l. 18% owg Tridefoam AGD Triquest XRD Technowet SW-1 Salt Dextrose Caustic Soda 50% Tricosulphur Black RC liq. Temperature 96° C for 30 minutes Procedure for Sulphur Dyes Procedure for Sulphur Dyes Salt, Dextrose, Caustic Tricosulphur Black RC liq. SW-1 Trioxy AL 96°C XRD 1°C min. 85°C AGD Soda 80°C 3°C min. Overflow rinse. 50°C 40°C 10’ 20’ 20’ 10’ 30’ 20’ Oxidation of suffur dyes Oxydation of this dye is very important to obtain good fastness. Alkaline Oxidation 1 gr./l. Soda ash 2% Trioxy AL 50 °C for 20 minutes Trioxy AL remains the best, since we stay in alkaline medium. The danger in the dyeing with sulphurs would be to leave the material in acid medium at the end of the cycle, which could lead to tenderizing of fibre by sulphuric acid formation during the warehousing time. Thank You! Visit WWW.TRITEX.COM THANK YOU !