EnSoft Corp.

advertisement

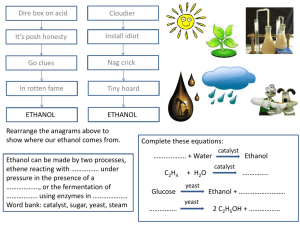

Microbes in service of humans J. (Hans) van Leeuwen Professor of Environmental and Biological Engineering & Vlasta Klima Balloun Professor Ames, IA, September, 2010 Towards a more sustainable future Small, but growing contribution Historical perspective Antiquity Microbial processes used long before development of microbiology as a science remnants of a fermented drink in fragments of 9,000-year-old Chinese vessels Antonie Philips van Leeuwenhoek (1632-1723) The very first microbiologist made small lenses by fusion and discovered and described both bacteria and protists. Also studied sperm cells and sections of plants and muscular fibers. Later became a Fellow of the Royal Society. The first systematic applications of microbiology Louis Pasteur (1822-1895) 1857 Microbiology of lactic acid fermentation 1860 Role of yeast in ethanolic fermentation • advances in applied microbiology led to the development of microbiology His discoveries reduced mortality from puerperal fever, and he created the first vaccine for rabies. He also made it important to make sure surgeries were more sterile. in 1888 he founded the Pasteur Institute and was named director. He is regarded as one of the main founders of modern microbiology, together with Ferdinand Cohn and Robert Koch. Microbial applications 1. Food and beverage biotechnology • fermented foods, alcoholic beverages (beer, wine, kumis, sake) distilled liquors • flavors 2. Enzyme technology • production and application of enzymes 3. Metabolites from microorganisms • amino acids • antibiotics, vaccines, biopharmaceuticals • bacterial polysaccharides and polyesters • specialty chemicals for organic synthesis (chiral synthons) Microbial applications (cont’d) 4. Biological fuel generation • production of biomass, ethanol/methane/butanol, single cell protein • microbial production/recovery of petroleum 5. Environmental biotechnology • water and wastewater treatment • composting (and landfilling) of solid waste • biodegradation/bioremediation of toxic chemicals and hazardous waste 6. Agricultural biotechnology • soil fertility • microbial insecticides, plant cloning technologies 7. Diagnostic tools • testing/diagnosis for clinical, food, environmental, agricultural applications • biosensors Ethanol production The major microbial biotechnology: beer, wine, distilled beverages, ethanol Saccharomyces (brewer’s yeast) • ethanolic fermentation • Embden-Meyerhof-Parnas, glycolytic pathway glucose + 2 ADP + 2 Pi ➞ 2 EtOH + 2 CO2 + 2 ATP • not a facultative anaerobe, cannot grow anaerobically indefinitely (unsaturated fatty acids and sterols can be synthesized only under aerobic conditions) • when oxygen present glucose oxidized via the Krebs cycle to CO2 and water (much biomass and little alcohol produced) Zymomonas mobilis • Alphaproteobacterium • osmotic tolerance, relatively high alcohol tolerance • higher specific growth rate than yeast • anaerobic carbohydrate metabolism through the Entner-Doudoroff pathway, yielding only 1 mol of ATP per mol of glucose ➞ more glucose converted to EtOH • limited substrate use, only 3 carbohydrates: glucose, fructose and sucrose • genetic engineering to expand substrate range Typical corn dry-grind ethanol plant Distillation Fermentor Water Enzymes Milling CO2 Yeasts Cooking Whole stillage Vapor Corn Evaporator DDG Dryer Thick stillage Centrifuge Commercial yeast production ………………………….. Vinegar Sour (spoiled ) wine, vinegar (from French): vin + aigre (sour) • Production in the US about 160 Mgal/y; 2/3 used in commercial products such as sauces and dressings, production of pickles and tomato products • Acetic acid bacteria are divided into two genera: Acetobacter aceti and Gluconobacter oxydans • Obligate aerobes that oxidize sugar, sugar alcohols and ethanol with the production of acetic acid as the major end product • Ethanol oxidation occurs via two membrane-associated dehydrogenases: alcohol dehydrogenase and acetaldehyde dehydrogenase Industrial production of acetic acid Trickling filter • vinegar manufacturing industry near Orleans in 14th century • trickling filter, wooden bioreactor (volume up to 60 m3) filled with beechwood shavings, acetic acid bacteria grow as biofilm • the ethanolic solution is sprayed over the surface and trickles through the shavings into a collection basin, and recirculated • temperature maintained at 29-35°C • about 12% acetic acid produced in 3 days • the life of a well-packed and maintained generator is about 20 years Submerged, batch process (Frings acetator) • stainless steel tank with a high-speed mixer microbes, air, ethanol and nutrients mixed for a favorable environment for microbial growth • 30°C maintained by circulation of cooling water • 12% acetic acid in about 35 h • production rate per m3 over 10 times higher than with surface “fermentation” and over 50% higher than with trickling filter Major organic acids from fermentation Product Microbe used Representative uses Fermentation conditions Acetic acid Acetobacter + ethanol Wide variety foods Single-step oxidation, 15%, 95-99% yields Citric acid Aspergillus niger + molasses Pharmaceuticals food additive High carbohydrate, controlled limit trace metals; 60-80% yld Fumaric acid Rhizopus nigricans + sugars Resin, tanning,sizing Strongly aerobic fermentation; C:N critical; Zn limit; 60% yld Gluconic acid Aspergillus niger + glucose + salts Carrier of Ca and Mg Agitation; 95% yields Itaconic acid Aspergillus terreus + molasses + salts Polymer of esters Highly aerobic; pH <2.2; 85% yield Kojic acid Aspergillus flavus-oryzae + carbohydrate + N Fungicides and insectides with metals Fe careful controlled to avoid reaction with kojic acid Lactic acid Homofermentative Lactobacillus delbrueckii Carrier of Ca and acidifier Purified medium used to facilitate extraction Lactic acid fermentation Pyruvate is reduced to lactic acid with the coupled reoxidation of NADH to NAD+ • lactic acid bacteria (e.g. Lactobacillus, Streptococcus) involved in many food fermentations • fermented milk, cheese, fermented vegetables Homolactic fermentation • glucose degraded via EMP pathway, with lactic acid as the only end product glucose + 2 ADP + 2 Pi ➞ 2 lactic acid + 2 ATP • carried out by Streptococcus, Pediococcus, Lactococcus, Enterococcus and various Lactobacillus species • important in dairy industry (yogurt, cheese) Heterolactic fermentation • glucose degraded via pentose phosphate pathway • in addition to lactic acid, also ethanol and CO2 produced glucose + ADP + Pi ➞ lactic acid + ethanol + CO2 + ATP Lactococcal products Nisin yield - 620 mg/L 6 Lactic acid production 5 4 0.4 3 2 Lactic acid Acetic acid 1 0 0 0 10 20 30 Fermentation time (h) 0h 16h 0.2 24h 40 Acetic acid (g/L) Lactic acid (g/L) Biomass yield - 2.3g/L 0.6 Milk fermentation microbes Single cell protein Microbial protein for use as human food/animal feed - source of low-cost protein? Advantages 1. rapid growth rate and high productivity 2. high protein content (30-80% of dw) 3. ability to utilize a wide range of cheap carbon sources methane, methanol, molasses, whey, lignocellulose waste, etc. 4. relatively easy selection of cells 5. little land area required 6. production independent of season and climate • protein content and quality largely dependent on the specific microbe utilized and on the fermentation process • fast growing aerobic microorganisms Some problems 1. high nucleic acid content (bacteria) 2. high protein content (elevated RNA levels – ribosomes • digestion of nucleic acids results in elevated levels of uric acid • treatment with RNAses 3. sensitivity or allergic reactions Microbes for SCP Carbon substrate Suitable microbes Carbon dioxide Spirulina sp., Chlorella sp. Liquid n-alkanes Saccharomycopsis lipolytica, Candida tropicalis Methane Methylomonas methanica, Methylococcus capsulatus Methanol Methylophilus methylotrophus, Hyphomicrobium sp. Candida boidinii, Pichia angusta Ethanol Candida utilis Glucose (hydrolyzed starch) Fusarium venetatum Inulin (polyfructan) Candida species, Kluyveromyces sp. Spent sulfite liquor Paecilomyces variotii (Pekilo process) Whey K. marxianus, K. lactis, P. cyclopium Lignocellulosic wastes Chaetomium sp., Agaricus bisporus, Cellulomonas sp. GRAS microorganisms Generally Regarded As Safe by the Food and Drug Administration Normally, these organisms need no further testing if cultivated under acceptable conditions Bacteria Bacillus subtilis Lactobacillus bulgaricus Leuconostoc oenos Yeasts Candida utilis Kluyveromyces lactis Saccharomyces cerevisiae Filamentous fungi Aspergillus niger Aspergillus oryzae Mucor circinelloides Rhizopus microsporus Penicillium roqueforti SCP examples Mushrooms Pekilo prossess • filamentous fungus Paecilomyces variotii • use of waste from wood processing (monosaccharides + acetate) • use as animal feed Pruteen • methanol (from methane - natural gas) as C1 carbon source • methylotrophic bacteria (Methylophilus methylotrophus) • feed protein Quorn • fungal mycelium, Fusarium graminarium for human consumption (mycoprotein) • processed to resemble meat MycoMax/MycoMeal Fungal Production and Water Reclamation Plant Fungal inoculum Screen Blowers Primary and secondary metabolites Primary metabolites • produced during active growth • generally a consequence of energy metabolism and necessary for the continued growth of the microorganism Substrate A ➞ Product Substrate A ➞ B ➞ C ➞ Product • ethanol, lactic acid,… Secondary metabolites • synthesized after the growth phase nears completion • a result of complex reactions that occur during the latter stages of primary growth Substrate A ➞ B ➞ C ➞ Primary metabolism (no product) ➘ D ➞ E ➞ Product of secondary metabolism Substrate A ➞ B ➞ C ➞ Primary metabolism (no product) afterwards, the product is formed by metabolism of an intermediate C ➞ D ➞ Product • growth phase = trophophase • idiophase = phase involved in production of metabolites • citric acid, antibiotics,… Secondary metabolite Primary metabolite Growth in batch Outline of fermentation design Amino acid production Citric acid Over 130,000 tons produced worldwide each year • used in foods and beverages • iron citrate as a source of iron preservative for stored blood, tablets, ointments,… in detergents as a replacement for polyphosphates • a microbial fermentation for production of citric acid developed in 1923 • >99% of the world’s output produced microbially Aspergillus niger • submerged fermentation in large fermenters • sucrose as substrate, and citric acid produced during idiophase • during trophophase mycelium produced and CO2 released • during idiophase glucose and fructose are metabolized directly to citric acid Antibiotics Antibiotics are small molecular weight compounds that inhibit or kill microorganisms at low concentrations • often products of secondary metabolism • the significance of antibiotic production is unclear, may be of ecological significance for the organism in nature • antibiotics produced by various bacteria, actinomycetes & fungi Bacillus Streptomyces Penicillium Streptomyces antibiotics Important antibiotics produced by Streptomyces species Microbial enzymes Microbial enzyme applications Enzyme applications, origins Mining with S and Fe bacteria Thiobacillus, Acidothiobacillus, Beggiatoa, and others Thiobacillus thiooxidans (Jaffe and Waksman 1922) • scattered in the Proteobacteria: α,β, γ subdivisions • acidophiles • chemolithotrophs: energy from oxidation of reduced sulfur compounds or iron • used in bioleaching of ores • problems with acid mine drainage Microbial mining with Thiobacillus Metal recovery from low-grade ores Slope, heap and in-situ leaching Metal recovery from low-grade ores Biobutanol Biobutanol can be produced by fermentation of biomass by the A.B.E. process. The process uses the bacterium Clostridium acetobutylicum, also known as the Weizmann organism. It was Chaim Weizmann who first used this bacteria for the production of acetone from starch (with the main use of acetone being the making of Cordite) in 1916. The butanol was a by-product of this fermentation (twice as much butanol was produced). The process also creates a recoverable amount of H2 and a number of other by-products: acetic, lactic and propionic acids, acetone, isopropanol and ethanol. Comparison of liquid fuels Air-fuel Specific ratio energy Heat of vaporization 14.6 2.9 MJ/kg air 0.36 MJ/kg 91–99 81–89 Butanol fuel 29.2 MJ/L 11.2 3.2 MJ/kg air 0.43 MJ/kg 96 78 Ethanol fuel 19.6 MJ/L 9.0 3.0 MJ/kg air 0.92 MJ/kg 129 102 Methanol 6.5 3.1 MJ/kg air 1.2 MJ/kg 136 104 Fuel Energy density Gasoline & 32 MJ/L biogasoline 16 MJ/L RON* MON* *Octane rating of a spark ignition engine fuel is the detonation resistance (anti-knock rating) compared to a mixture of iso-octane (2,2,4-trimethylpentane, an isomer of octane) and n-heptane. By definition, iso-octane is assigned an octane rating of 100, and heptane is assigned an octane rating of zero. An 87-octane gasoline, for example, possesses the same anti-knock rating of a mixture of 87% (by volume) iso-octane, and 13% (by volume) n-heptane. Utilization of resources Algal and cyanobacterial cultivation High-rate photosynthesis J. (Hans) van Leeuwen Cyanobacteria Chloroplasts in plants and eukaryotic algae have evolved from cyanobacteria via endosymbiosis. Certain cyanobacteria produce cyanotoxins including anatoxin-a, anatoxin-as, aplysiatoxin, cylindrospermopsin, domoic acid, microcystin LR, nodularin R (from Nodularia), or saxitoxin. Sometimes a mass-reproduction of cyanobacteria results in algal blooms. These toxins can be neurotoxins, hepatotoxins, cytotoxins, and endotoxins, and can be dangerous to animals and humans. Several cases of human poisoning have been documented but a lack of knowledge prevents an accurate assessment of the risks. Anabaena malodorous products 2-Methylisoborneol IUPAC name 1,6,7,7Tetramethylbicyclo[2.2.1] heptan-6-ol Other names 2-Methyl-2-bornanol, MIB Geosmin IUPAC name Identifiers 4,8a-dimethyldecalin-4a-ol or, (4S,4aS,8aR)-4,8a-dimethyl1,2,3,4,5,6,7,8octahydronaphthalen-4a-ol Identifiers CAS number 2371-42-8 CAS number 19700-21-1 PubChem 16913 PubChem 29746 SMILES CC1(C2CCC1(C(C2)(C) O)C)C SMILES CC1CCCC2(C1(CCCC2)O)C Properties Properties Molecular formula C11H20O Molecular formula C12H22O Molar mass 168.28 g/mol Molar mass 182.30248 g/mol Algal oil production Microalgae have much faster growth-rates than terrestrial crops. The per unit area yield of oil from algae is estimated to be from between 5,000 to 20,000 US gallons per acre per year (4,700 to 18,000 m3/km2·a); this is 7 to 30 times > than the next best crop, Chinese tallow (700 US gal/acre·a or 650 m3/km2·a). Typical yield of biodiesel/ha Some typical yields Crop Algae Chinese tallow[ 1, 2] Palm oil [3] Coconut Rapeseed [3] Soy (Indiana) Peanut [3] Sunflower [3] Hemp Yield L/ha US gal/acre ~3,000 ~300 772 97 780-1490 2150 954 76-161 138 126 242 508 230 102 8-17 90 82 26 1.^ Klass, Donald, "Biomass for Renewable Energy, Fuels, and Chemicals", page 341. Academic Press, 1998. 2.^ Kitani, Osamu, "Volume V: Energy and Biomass Engineering,CIGR Handbook of Agricultural Engineering", Am Society of Agricultural Engs, 1999. 3. Biofuels: some numbers Spirulina Spirulina Domain: Bacteria Phylum: Cyanobacteria = Chroobacteria Spirulina common name for food supplements from two species of cyanobacteria: Arthrospira platensis, and Arthrospira maxima. These and other Arthrospira species were once classified in the genus Spirulina. There is now agreement that they are a distinct genus, and that the food species belong to Arthrospira; nonetheless, the older term Spirulina remains the popular name. Spirulina is cultivated around the world, and is used as a human dietary supplement as well as a whole food and is available in tablet, flake, and powder form. It is also used as a feed supplement in the aquaculture, aquarium, and poultry industries.[1] Order: Oscillatoriales Family: Phormidiaceae Genus: Arthrospira Species About 35 •Arthrospira maxima •Arthrospira platensis Spirulina farming Edible algae Dulse (‘’Palmaria palmata’’) is a red species sold in Ireland and Atlantic Canada. It is eaten raw, fresh, dried, or cooked like spinach Edible algae: Porphyra [5] Domain: Eukaryota (unranked): Archaeplastid a Phylum: Rhodophyta Class: Bangiophyce ae Order: Bangiales Family: Bangiaceae Genus: Porphyra Porphyra the most domesticated of the marine algae, known as laver, nori (Japanese), amanori (Japanese),[6] zakai, kim (Korean),[6] zicai (Chinese),[6] karengo, sloke or slukos.[2] The marine red alga has been cultivated extensively in Asian countries as edible seaweed to wrap rice and fish that compose the Japanese food sushi, and the Korean food gimbap. Japanese annual production of Porphyra spp. is valued at 100 billion yen (US$ 1 billion).[7] Chondrus crispus Kingdom: Archaeplastida (earlier Plantae) Phylum: Rhodophyta Class: Rhodophycea e Order: Gigartinales Family: Gigartinaceae Genus: Chondrus Species: C. crispus Irish moss (Chondrus crispus), often confused with Mastocarpus stellatus, is the source of carrageenan, which is used as a stiffening agent in instant puddings, sauces, and dairy products such as ice cream. Irish moss is also used by beer brewers as a fining agent. Other uses of algae Fertilizer and agar For centuries seaweed has been used as fertilizer. It is also an excellent source of potassium for manufacture of potash and potassium nitrate. Both microalgae and macroalgae are used to make agar. Pollution Control With concern over global warming, new methods for the thorough and efficient capture of CO2 are being sought out. The carbon dioxide that a carbon-fuel burning plant produces can feed into open or closed algae systems, fixing the CO2 and accelerating algae growth. Untreated wastewater can supply additional nutrients, thus turning two pollutants into valuable commodities. Algae cultivation is under study for uranium/plutonium sequestration and purifying fertilizer runoff. Chlorella, particularly a transgenic strain which carries an extra mercury reductase gene, has been studied as an agent for environmental remediation due to its ability to reduce Hg2+ to the less toxic elemental mercury. Cultivated algae serve many other purposes, including bioplastic production, dyes and colorant production, chemical feedstock production, and pharmaceutical ingredients. Sea otters and kelp Fast Facts Type: Mammal Diet: Carnivore Average lifespan in the wild: 23 y Size: 4 ft (1.25 m) Weight: 65 lbs (30 kg) Protection status: Threatened Tool using sea otters SEA O TTERS ABALO N E KELP & URCHIN S Sea otter distribution Diet Sea urchins, abalone, mussels, clams, crabs, snails and about 40 other marine species. Sea otters eat approximately 25% of their weight in food each day. Sea otters were hunted for their fur to the point of near extinction. Early in the 20th century only 1,000 to 2,000 animals remained. Today, 100,000 to 150,000 sea otters are protected by law. Importance to kelp protection For discussion Hypoxia Gulf of Mexico "Dead Zone" due to excessive algal growth supported by fertilizer runoff in the Mississippi Low-oxygen areas appear in red. (NASA and NOAA)