poster_Reactor

advertisement

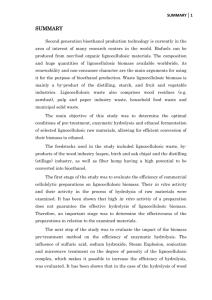

Large-scale pretreatment of lignocellulosic biomass for bioethanol production in a pilot plant José Antonio Pérez Jiménez*, Manuel Jesús Díaz Villanueva, Guadalupe Pinna Hernández Department of Biomass, CTAER Andalucía Foundation, Scientific and Technology Park, GEOLIT, Jaén (Spain) *Corresponding e-mail: joseantonio.perez@ctaer.com RELATED WORKS IN LABORATORY SCALE INTRODUCTION Mediterranean Biomass is an attractive lignocellulosic substrate for bioconversion to second generation ethanol because it has high carbohydrate content and is present in large quantities in Andalucía (Spain). For efficient ethanol production from this kind of biomass by biochemical pathway it should be firstly pretreated to make the cellulose more accesible to enzymatic hydrolisis and to recover more effectively the hemicellulose. Although hydrotermal pretreatments have been studied (at laboratory scale) only few papers can be found in the literature about the use of a high scale liquid hot water (LHW) treatment to fractionate this material. As main advantages, LHW improves the recovery of the pentoses and produces hydrolysate that results in little or no inhibition of solubilized sugar fermentation. OLIVE TREE PRUNNING LHW (210 ºC, 10 min) (Cara et al. 2007) SUNFLOWER STALKS LHW (220 ºC, 5 min) (Díaz et al. 2011) 4.5 kg of solid fraction 6.7 kg of solid fraction 1 L ethanol 1 L ethanol MATERIALS AND METHODS TECHNICAL SPECIFICATIONS OF PILOT PLANT LOAD REACTOR DOWNLOAD REACTOR HEAT SYSTEM CONTROL FILTRATION LOAD REACTOR SATAINLESS STEEL: AISI 316L TOTAL CAPACITY: 100 LITRES DESIGN PRESSURE: 50 bar. MAXIMUM TEMPERATURE OF WORKING: 240 ºC INNER DIAMETER: 450 mm HEIGHT: 560 mm HEAT: DUAL CHAMBER THERMAL-FLUID AGITATION: MECHANICAL (1.5 KW 1500 RPM) DOWNLOAD REACTOR SATAINLESS STEEL: AISI 316L TOTAL CAPACITY: 300 LITRES DESIGN PRESSURE: 8 bar. MAXIMUM TEMPERATURE OF WORKING: 240 º C INNER DIAMETER: 720 mm HEIGHT: 700 mm COOLING: DUAL CHAMBER WITH WATER AGITATION: MECHANICAL (1.5 KW 1500 RPM) RAW MATERIAL (LIGNOCELLULOSIC) PRETREATMENT (LHW) SOLID FRACTION LIQUID FRACTION (HYDROLYSATE) ENZYMATIC HYDROLYSiS FERMENTATION FERMENTATION ANALYTICAL METHODS The raw material composition is determined according to the National Renewable Energy Laboratory analytical methods for biomass. PILOT PLANT IN LABORATORY BIOMASS ETHANOL ETHANOL CONCLUSIONS i. Evaluate pretreatment, enzymatic hydrolysis and fermentation conditions for bioethanol production process from lignocellulosic material at large-scale is essential to determine process optimum conditions which lead to industrial implementation of this technology. ii. Cellulose is the main carbohydrate source to be used for hydrolysis and fermentation into ethanol. Therefore, to provide high cellulose content residues after pretreatment avoiding cellulose solubilisation is one of the major determinants of pretreatment efficiency. iii. Statistical designs are used to find the optimal temperature, residence time, pressure, particle size and solid/liquid ratio conditions, considering recovery value of hemicellulose sugars in prehydrolyzate and cellulose digestibility of solid fraction (measured as enzymatic hydrolysis yield in standard test using commercial cellulases) as response variables. RELATED WORKS Cara C, Romero I, Oliva JM, Sáez F, Castro E . (2007). Liquid hot water pretretment of olive tree pruning residues. Appl Biochem Biotecnol 136-140, 379-394. Pérez JA, Balleteros I, Ballesteros M, Sáez F, Negro JM, Manzanares P . (2008). Optimizing liquid hot water conditions to enhance sugar recovery from wheat straw for fuel-ethanol production. Fuel 87, 3640-3647. Díaz MJ, Cara C, Ruiz E, Pérez-Bonilla M, Castro E. (2011). Hydrotermal pre-treatment and enzymatic hydrolysis of sunflower stalks.. Fuel 90, 3225-3229. ACKNOWLEDGEMENTS -