Lecture 7 - National University of Singapore

advertisement

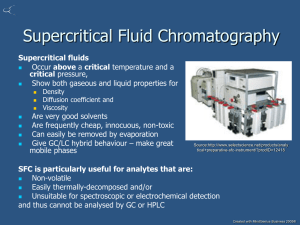

Week #7 Novel Pharmaceutical Particles Chi-Hwa Wang Department of Chemical and Biomolecular Engineering, National University of Singapore, 4 Engineering Drive 4, Singapore, 117576, Singapore. E-mail: chewch@nus.edu.sg. Advanced Drug Delivery Systems Computation Simulation and Optimization Optimized Strategy for Cancer Therapy Patient Specific Treatment Novel Fabrication of Nano-/Micro-particles NUS Presentation Title 2001 Novel Fabrication of Pharmaceutical Particles Electrohydrodynamic atomization applications Micro- and nanofibers. Thin films. Micro- and nanoparticles. Microencapsulation of living cells, DNA etc. Paclitaxel Chemotherapy & radiotherapy for brain tumors. Penetrates the blood-brain barrier poorly. Ijsebaert J. C., K. B. Geerse, J. C. M. Marijnissen, J. J. Lammers, P. Zanen. Electro-hydrodynamic atomization of drug solutions for inhalation purposes, J. Appl. Physiol. (2001) 91: 2735-2741. Loscertales I. G., A. Barrero, I. Guerrero, R. Cortijo, M. Marquez, A. M. Ganan-Calvo. Micro/nano encapsulation via electrified coaxial liquid jets, Science (2002) 295: 1695-1698. Ding L. N., T. Lee, C. H. Wang. Fabrication of monodispersed Taxol-loaded particles using electrohydrodynamic atomization, J. Control. Rel. (2005) 102(2):.395-413. Xie J., C.M.M Jan, C.H. Wang. Microparticles developed by electrohydrodynamic atomization for the local delivery of anticancer drug to treat C6 glioma in vitro. Biomaterials (2006) 27: 3321-3332 Xie J., C.H. Wang, “Electrospun micro- and nanofibers for sustained delivery of paclitaxel to treat C6 glioma in vitro” Pharmaceutical Research , (2006) 23, 1817-1826. Xie J., L.K. Lim, Y. Phua, J. Hua, C.H. Wang “Electrohydrodynamic atomization for biodegradable polymeric particle production” J. Colloid & Interface Sci., 302, 103–112 (2006). NUS Presentation Title 2001 Electro-hydrodynamic Atomization Process Using electric field to break liquid drops into fine droplets Syringe Vn Filter Vr Particles Vacuum pump N2 Vn Vr : the trace of protective Nitrogen; : solvent with polymer & drugs; : volatilized solvent; : collected polymer & drug particles; : high voltage used to break liquid drops; : high voltage applied to metal hoop; NUS Presentation Title 2001 Electrohydrodynamic atomization process Vn Vn Vg Vn 0 Vn Vr Vr Vg Vr 0 Vr Vg 0 Electrohydrodynamic atomization is an atomization method based on the application of an electrical stress on the fluid that emerges from the tip of the nozzle. A Taylor cone, which is formed due to the acceleration of the fluid by the applied electrical stress, reduces the diameter of the jet, so that a thin jet is formed at the tip of the Taylor cone. Depending on the solution properties, either discrete particles or strands of fibers can be formed using the same equipment. Droplet Size Variation with Different Ring Electrical Potential (Vr) Vn=5kV, 3ml/h 140 Vn=8kV, 3ml/h Droplet Size (micron) 120 Linear (Vn=5kV, 3ml/h) 100 Linear (Vn=8kV, 3ml/h) 80 II 60 40 20 I 0 1.5 3.5 5.5 Vr (kV) 7.5 9.5 I: changes in droplet size when Vn is kept at 5kV. II: changes in droplet size when Vn is kept at 8kV. Particle Size Mass balance Droplet Size Modulation Varying Vr Taylor Cone, jet and droplet formation process Nozzle Wall Taylor Cone Jet 320 micron Droplet Formation The Front Tracking/Finite Difference CFD simulation was able to replicate all observable phenomenon of the EHDA process, including the Taylor Cone, Jet and the droplet formation process. Since the electrical charge resides on the surface of the liquid, the electrical field accelerates the surface of the liquid, and results in the formation of the circulating fluid inside the Taylor cone. Fluid: Dichloromethane; Flowrate: 6ml/h; Vn=8kV, Vr=8.9kV Nozzle inner radius: 110 micron; Nozzle outer radius: 170 micron Nozzle to Ring: 10mm; Nozzle to Ground: 100mm; Ring Diameter: 40mm Taylor Cone, jet and droplet formation process Nozzle Diameter ~ 340micron Droplet Diameter ~ 50micron A transient CFD simulation was done, so that the formation of the Taylor Cone, jet and droplet was captured with time. Droplet formation was also simulated and the simulated droplet size can be obtained directly from the simulation data. Fluid: Dichloromethane; Flowrate: 6ml/h; Vn=8kV, Vr=8.9kV Nozzle inner radius: 110 micron; Nozzle outer radius: 170 micron Nozzle to Ring: 10mm; Nozzle to Ground: 100mm; Ring Diameter: 40mm A B C A: Eggers, J. Fluid. Mech., 262, 205, 1994; B: CFD simulation results; C: Chaudhary, J. Fluid. Mech., 96, 275, 1980 Closer look of Taylor Cone formation CFD simulation Experimental The Taylor Cone is an important phenomenon in the EHDA process, enabling the formation of thin jet that is at least one order of magnitude smaller than the inner diameter of the nozzle, resulting in droplets that is smaller than the inner diameter of the nozzle. The Taylor cone angle is also a useful parameter for comparison between the experimental and the simulation results. Fluid flow field Fluid: Dichloromethane; Flowrate: 6ml/h; Vn=8kV, Vr=8.9kV Nozzle inner radius: 110 micron; Nozzle outer radius: 170 micron Nozzle to Ring: 10mm; Nozzle to Ground: 100mm; Ring Diameter: 40mm Electrohydrodynamic Atomization NUS Presentation Title 2001 Taylor cone Jet Charged droplets J. Xie, J. C. M. Marijnissen, C. H. Wang. Biomaterials. 27: 3321-3332 (2006). J. Xie, L. K. Lim, Y. Y. Phua, J. Hua, C. H. Wang. Journal of Colloids and Interface Science. 302, 103–112 (2006). EHDA Microparticles Xie J, Jan CMM, Wang CH. Microparticles developed by electrohydrodynamic atomization for the local delivery of anticancer drug to treat C6 glioma in vitro. Biomaterials 2006; 27: 3321-3332 NUS Presentation Title 2001 Different polymer solution flow rates. a: 3.0 ml/h size: 11±0.8μm; b: 1.0 ml/h size: 6.5±0.8μm; c: 0.5 ml/h size: 4.9±0.8μm. d: 3ml/h size 17μm; e: 10ml/h size 26μm; f: 15ml/h size 32μm. I KQ 1 K: Conductivity Q: flow rate d: diameter of droplets γ: surface tension I: current (d) (b) (e) (c) (f) 2 1 4 Q 6 0 d c Q1/ 2 I 2 (a) EHDA Microparticles a b c d e f g h NUS Presentation Title 2001 Operating parameters Polymer Polymer Polymer solution Air flow The voltage The voltage Nozzle concentration flow rate rate of nozzle of ring size Samples S1 S2 S3 S4 PCL PLGA PLGA PLGA 6% 8% 8% 8% 3ml/h 5ml/h 5ml/h 5ml/h 25L/min 25L/min 25L/min 25L/min 9.8kV 10.0kV 10.0kV 10.0kV 7.1kV 9.0kV 9.0kV 9.0kV 0.91mm 0.91mm 0.91mm 0.91mm Variation of operating parameters results in controllable size and morphology of microparticles. Xie J, Jan CMM, Wang CH. Microparticles developed by electrohydrodynamic atomization for the local delivery of anticancer drug to treat C6 glioma in vitro. Biomaterials 2006; 27: 3321-3332. SEM images microparticles (a, b: S1; c, d: S2; e, f: S3; g, h: S4) EHDA Microparticles NUS Presentation Title 2001 Characterization for samples S1 – S5. Samples S1 S2 S3 S4 S5 Drug loading (%) Encapsulation Efficiency (%) 8.1 7.9 8.4 15.8 0 81.3 82.3 84.1 78.1 - Particle size (μm) ± SD 11.4 ± 0.9 15.2 ± 1.7 14.2 ± 2.2 15.1 ± 0.7 12.6 ± 0.8 S1 - Paclitaxel-loaded PCL microspheres S2 - Paclitaxel-loaded PLGA microspheres S3 - Paclitaxel-loaded PLGA particles of biconcave shape S4 – Paclitaxel-loaded PLGA microspheres S5 – Blank PLGA microspheres Xie J, Jan CMM, Wang CH. Microparticles developed by electrohydrodynamic atomization for the local delivery of anticancer drug to treat C6 glioma in vitro. Biomaterials 2006; 27: 3321-3332. EHDA Microparticles NUS Presentation Title 2001 In vitro release Cumulative release (%) 80 70 S1 60 S2 S1: 10% PCL Microspheres S2: 10% PLGA Microspheres S3 50 S4 S3: 10% PLGA Biconcave 40 S4: 20% PLGA Microspheres 30 20 Xie J, Jan CMM, Wang CH. Microparticles developed by electrohydrodynamic atomization for the local delivery of anticancer drug to treat C6 glioma in vitro. Biomaterials 2006; 27: 3321-3332. 10 0 0 5 10 15 20 25 30 35 Tim e (day) Initial burst due to dissolution and diffusion of paclitaxel on the surface layer of the microspheres proved by XPS results. Paclitaxel-loaded PLGA microparticles could release faster than paclitaxel-loaded PCL microparticles. Biconcave-shaped PLGA microparticles may release slightly faster than PLGA microspheres. 20% paclitaxel-loaded PLGA microparticles could release slightly faster than 10% paclitaxel-loaded samples. The total amount of paclitaxel released seemed to be less than 60% of the total amount of drug in the microparticles. EHDA Microparticles (d) (g) (b) (e) (h) (c) (f) (i) NUS (a) Presentation Title 2001 Representative optical images of C6 glioma cells after being treated by paclitaxel-loaded PLGA microparticles ( 50μm). a, b, c: 250μg/ml 1, 2, 5 day; d, e, f: 1250μg/ml 1, 2, 5day; g, h, i: 2000μg/ml 1, 2, 5 day. Optical microscope EHDA Microparticles NUS Presentation Title 2001 Cell viability Xie J, Jan CMM, Wang CH. Microparticles developed by electrohydrodynamic atomization for the local delivery of anticancer drug to treat C6 glioma in vitro. Biomaterials 2006; 27: 3321-3332. 120% 120% 1day 100% 2days 100% 1day 3days Cell viability (%) Cell viability (%) 2days 3days 80% 4days 5days 60% 40% 40% 20% 0% 0% 20 40 60 80 100 120 140 Taxol concentration (μg/ml) 160 5days 60% 20% 0 4days 80% 0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 Paclitaxel-loaded PLGA microparticle concentration (μg/ml) The values of IC50 for Taxol and paclitaxel-loaded microspheres after 5days are around 14μg/ml and 160μg/ml, respectively. (Actual amount of paclitaxel: 160×10%*0.8=12.8 μg/ml). IC50 (inhibitory concentration 50%) represents the concentration of a drug that is required for 50% inhibition in vitro. NUS Presentation Title 2001 Electrospinning Taylor cone Jet Fibers Schematic of electrospinning setup Representative image of electrospinning jet with the exposure time of 10ms. 0mM 1mM 5mM Polymer NUS Presentation Title 2001 concentration 15% 0mM 1mM 5mM 10% 110±16nm 100±14nm 1mM 5mM 15mM 0mM 10mM 15mM 5% 82±11nm Tetrabutylammonium tetraphenylborate (TATPB) 2% Ionic surfactant Increasing conductivity 45±7nm 31±5nm Electrospun Micro- and Nano-fibers NUS Presentation Title 2001 SEM images of paclitaxel-loaded PLGA Fibers Cross section 10% paclitaxel-loaded 10% paclitaxel-loaded PLGA nanofiber PLGA microfiber before release Diameter: 14.5mm Thickness: 1mm Characterization of paclitaxel-loaded fibers Samples Fibers mean diameter Drug loading (%) Encapsulation efficiency (%) PLGA MF (s1) 2.5±0.32 µm 9.9±0.1 99.0±1.0 PLGA NF (s2) 770±13 nm 9.2±0.03 92.0±0.3 http://www.drugs.com/PDR/Gliadel_Wafer.html Results and discussion Electrospinning Micro- and Nano-fibers NUS Presentation Title 2001 J. Xie, C.H. Wang, “Electrospun Micro- and Nanofibers for Sustained Delivery of Paclitaxel to Treat C6 Glioma In Vitro” Pharmaceutical Research , 23, 1817-1826 (2006). Laser scanning confocal microscopy images Cell morphology after 72h incubation with different formulations Blank PLGA nanofibers 10% Paclitaxel-loaded PLGA nanofibers 1000µg/ml 10% Paclitaxel-loaded PLGA nanofibers 500µg/ml 10% Paclitaxel-loaded PLGA nanofibers 2000µg/ml 10× green colour indicates living cells stained with FDA Results and discussion Electrospinning Micro- and Nano-fibers NUS Presentation Title 2001 J. Xie, C.H. Wang, “Electrospun Micro- and Nanofibers for Sustained Delivery of Paclitaxel to Treat C6 Glioma In Vitro” Pharmaceutical Research , 23, 1817-1826 (2006). Cell viability after 72h incubation with different formulations. 120 Cell viability (%) 100 The IC50 value of paclitaxel-loaded PLGA nanofibers was around 1200µg/well. 80 60 IC50 of paclitaxel of this formulation was about 36µg/ml, which was comparable to the commercial paclitaxel formulation Taxol® (30µg/ml). 40 20 0 Control Blank PLGA NF PLGA NF 500 PLGA NF 1000 PLGA NF 2000 Different formulations PLGA NF500: 500µg/ml; PLGA NF 1000: 1000µg/ml; PLGA NF 2000: 2000µg/ml. NUS Presentation Title 2001 In-Vovo Experiment Overview: Tumor Volume Response Subcutaneous Inoculation with 1x 106 C6 giloma cells Balb/c Nude mice Disc (Surgical Implantation) Microspheres (Surgical Implantation) a Microparticles b Tumor _ Vol (Intra-tumor injection) 1 ab 2 6 After period of tumor growth, Microparticles, Discs or Microspheres are implanted In-Vovo Experiment Overview: Tumor Volume Response Representative pictures of tumours after 21days of C6 glioma cells implantation Blank Microspheres 10% Taxol loading EHDA Microparticles Taxol® 20% Taxol loading EHDA Microparticles NUS Presentation Title 2001 Tumor volume response: Paclitaxel EHDA Microparticles 6000 Blank Microparticles Tumor was allowed to grow for a period of 14 days before 1st injection of microparticles and commercial taxol (for control were administered) directly into the tumor mass. Commercial Taxol - 1 mg Taxol 5000 Tumore volume (mm3) Microparticle 20% Taxol Loading - 1 mg Taxol 4000 3000 20% Taxol Loading group had 1 mg taxol administered in two doses of 0.5 mg as injection directly into the tumor on Day 14 & 21. 2000 1000 0 0 5 10 15 20 Tim e (days) 25 30 35 40 70 EHDA Microparticles in vitro release profile Cumulative release (%) 60 Significant tumor growth suppression for at least 7 days after first injection (30 % in vitro release reached). 50 Tumor volume is among lowest of treatment (see next slide). 40 30 No significant variation of animal weight from controls were observed. Indicating minimal or no systemic toxicity effects. 20 10% PLGA EHDA Microparticles 10 20% PLGA EHDA Microparticles 0 0 5 10 15 20 Time (day) 25 30 35 40 NUS Presentation Title 2001 In-Vovo Experiment Overview: Tumor Volume Response In vivo release profile of EHDA microparticles 14% drug loaded EHDA microparticles In vivo release profile for 14.8% Drug Loaded EHDA Microparticles 3.50 23.6 ± 6.5 ng/ml EHDA microparticles ng Paclitaxel/ ml Plasma 3.00 Control EHDA Microparticles Control 2.50 2.00 1.50 1.00 0.50 0.00 2 7 10 14 17 Days after Implantation 21 Days after implantation 28 Weight loss observed in control group over first seven days. No weight loss observed for EHDA group. Control group showed Paclitaxel cleared from Plasma after 10 days. Sustained delivery observed for Experimental group for up to 28 days. Particle Fabrication Techniques for Pharmaceutical Applications Biomedical Devices Developed by Electrohydrodynamic Atomization (EHDA) Technique Electrohydrodynamic atomization (EHDA) is a process, also called electrospray, where a liquid jet breaks up into fine droplets under the influence of electrical forces. With increasing electric forces, different spray modes can be obtained from dripping mode, single cone-jet mode to multiple-cone mode. After the solvent evaporates, polymeric particles can be obtained. Electrospinning of liquids involves the introduction of electrostatic charges to a stream of polymeric fluid in the presence of strong electric field. After the fluid evaporates, fibers can be formed. Typical jet of electrospray and electrospinning Representative optical images of C6 glioma cells after being treated by different concentrations of paclitaxel-loaded PLGA microparticles Typical biomedical devices including gel microbeads, microparticles, films and fibers. Tumor volume variation with time The research efforts of this project are to develop various biomedical devices for applications in controlled release of bioactive materials using electrohydrodynamic atomization techniques. Through investigation of the processing parameters during the EHDA process, controllable size and morphology of particles, controllable diameters of fibers and controllable thicknesses of films were successfully achieved. Singapore-MIT Alliance Nanoparticle fabrication of biodegradable polymers using supercritical antisolvent: Effects of mixing and thermodynamic properties Nanoparticle fabrication Advantages of CO2 Methods of Fabrication •“green” solvent, environmentally benign •Readily available and inexpensive •Low critical pressure and temperatures Emulsion methods (O/W; W1/O/W2) Spray drying (Microparticles) RESS Rapid Expansion of Supercritical Solutions (Debenedetti et al. (1993) Fluid Phase Equilibria 82, 311-321) ASES Aerosol Solvent Extraction System Electrohydrodynamic atomization (EHDA) (Micro and nanopartices) Dialysis (nanoparticles) Supercritical fluid techniques (Micro and nanoparticles) (Bleich et al. (1993) Int. J. Pharma., 97, 111-117) SEDS Solution Enhanced Dispersion by Supercritical Fluids (Ghaderi et al. (1999) Pharma. Res., 16(5), 676 – 681) SAS Supercritical AntiSolvent (Reverchon et al. (2003) Ind. Eng, Chem. Res., 42, 6405 – 6414) SASEM Supercritical Antisolvent with Enhanced Mass Transfer (Chattopadhyay et al. (2002) Ind Eng Chem Res., 41, 6049 – 6058) Supercritical antisolvent Most organic solvents are soluble in supercritical CO2 Low critical temperature (31.1 deg C) Suitable for processing thermally labile pharmaceuticals Polymer Drug Removal of organic solvent from product Organic solvent Capillary nozzle Small orifice Coaxial nozzles Assisted jet breakup Enhanced mixing Ultrasonic nozzles Uniform atomization Enhanced mass transfer in vessel Hydrodynamics and thermodynamics Both hydrodynamics and thermodynamics play a role in influencing the Supercritical antisolvent process for polymer particle formation Diego and coworkers (2005) identified the two regimes of particle formation for precipitation of polymers in the PCA process Below mixture critical pressure, the solution droplets were obtained and mass transfer takes place between the solution droplets and CO2 Initial size of droplets influences the particle size Above mixture critical pressure, solution enters the supercritical CO2 as a gaseous plume Turbulent mixing of solution and CO2 Mass transfer and mixing influence the particle size Fibers or discrete particle may be obtained Diego et al. (2005) Operating regimes and mechanism of particle formation during the precipitation of polymers using the PCA process. J. Supercritical fluids, 35, 147 - 156 Hydrodynamics Carretier and coworkers (2003) investigated the hydrodynamics of the SAS process for precipitation of PLA particles from methylene chloride (DCM) solution Jet formation and breakup at supercritical pressures Varying liquid flow rates (0.25 – 3 ml/min) Jet breakup length dependent on the spray Reynolds number Fibers or microparticles were obtained depending on liquid flow rates Chattopadhyay and Gupta (2001) developed the supercritical antisolvent with enhanced mass transfer (SASEM) for production of uniform sized nanoparticles Ultrasonic assisted atomization of jet Enhanced mass transfer between organic solution and supercritical CO2 phases E. Carretier et al. (2003) Hydrodynamics of Supercritical Antisolvent Precipitation: Characterization and influence on particle morphology. Ind. Eng, Chem, Res, 42, 331 – 338 P. Chattopadhyay and R. B. Gupta, Production of griseofulvin nanoparticles using supercritical CO2 antisolvent with enhanced mass transfer. Int. J. Pharma. 228 (2001) 19 – 31 Objectives Fabrication of nanoparticles of biodegradable polymers Controlled release purposes Model drug: Paclitaxel (hydrophobic) Polymer studied: Poly L lactide (PLA) Organic solvent used: Methylene chloride (DCM) 1. Effect of thermodynamic conditions on particle properties Constant operating temperature 35 deg C Varying operating pressure 73.8 bar – 95 bar 2. Effect of hydrodynamics Jet formation in supercritical fluid Jet flow rate 3. Effect of mixing on particle formation Supercritical antisolvent (SAS) process Ultrasonication for mixing with the high pressure vessel SAS setup V1 P1 C2 F2 PI CO2 V2 C1 P2 TC F1 V3 Modified SASEM setup V1 P1 C2 U1 PI CO2 V2 C1 P2 TC F1 U1: Ultrasonic system; Branson sonifier and converter, Sonics and Materials probe (3/8” probe tip diameter) F2 V3 Particle fabrication 1. Pressurization (CO2) 2. Spraying (Organic solution jet) High pressure pump was used to deliver liquefied CO2 to high pressure vessel Temperature in high pressure vessel was maintained using circulating water bath High pressure liquid pump was used to deliver organic solution (Solvent + pharmaceutical) into the high pressure vessel via a capillary nozzle Vertical jet (SAS) Horizontal jet (modified SASEM with ultrasonication) Flowrate may be controlled by HPLC pump 3. Venting 4. Purging Organic solvent – CO2 mixture was vented off to a fume cupboard from the bottom of the vessel Filter frit (0.22mm) was placed at bottom of the vessel to collect particles Vessel was purged using fresh CO2 to remove any remaining organic solvent SAS setup Flow rate = 4ml/min Reynolds number = 292 Jet breakup after entering high pressure CO2 Jet breakup length is dependent on spray Reynolds number No external mixing in the high pressure vessel during precipitation Effect of varying pressure Experimental conditions Solution flow rate was kept constant at 4ml/min System temperature was maintained at 35 deg C 2% polymer loading in DCM Pressure varied from 73.8 to 95 bars 73.8 bars 80 bars Effect of varying pressure 90 bars Smoother surface morphology particles obtained Particle sizes were highly polydispersed 95 bars Effect of varying pressure Results obtained Particle sizes of 5 – 10 mm were obtained At 73.8 bars, particles obtained were agglomerated and surfaces were very rough At 80 bars and above, spherical particles with little agglomeration were achieved As supercritical pressure increases, particle morphology improves For particles obtained at 90 and 95 bars, smooth surface morphology were obtained This suggests that as pressure increases, better mass transfer between CO2 and DCM during the spraying process More rapid precipitation Less agglomeration Effect of varying solution flowrate Temperature: 35 deg C Pressure: 90 bars 2% polymer loading in DCM Solution flowrate of 2, 4, 6 ml/min 4 ml/min 2 ml/min 6 ml/min Effect of varying solution flowrate Count intensity (%) 12 4ml/min 10 Mean Size: 3.03 mm SD: 2.25 mm 8 6 4 2 18 9. 6 9 8. 4 Particle size (mm) 6ml/min 16 Mean Size: 2.05 mm SD: 1.21 mm 14 12 10 8 6 4 2 Particle size (mm) 9. 6 9 8. 4 7. 8 7. 2 6. 6 6 5. 4 4. 8 4. 2 3. 6 3 2. 4 1. 8 1. 2 0 0. 6 Count intensity (%) 7. 8 7. 2 6. 6 6 5. 4 4. 8 4. 2 3. 6 3 2. 4 1. 8 1. 2 0. 6 0 Effect of varying flowrate Results obtained At 90 bar and 35 deg C, powdery particles with little/no agglomeration were obtained Particles obtained have similar surface morphologies Polydispersed particles Clusters of small particles (< 2 mm) Larger particles (2-10 mm) Higher liquid flowrate generally decreases the particle size for the larger particles Shorter jet breakup length Better mass transfer between the organic solvent and supercritical CO2 Modified SASEM setup Jet breakup is not due to liquid film disintegration from ultrasonic vibrating surface Enhanced turbulence and mixing of jet in the high pressure cell due to ultrasonic vibration Jet break up Turbulence and mixing Effect of ultrasonication Comparison of SAS (No external mixing) and modified SASEM 10w/w% paclitaxel loaded PLA particles 2% polymer loading in DCM No ultrasonication Polydispersed particles obtained Mean Size: 4.13 mm SD: 1.98 mm Effect of ultrasonication Particles obtained with ultrasonication 30 mm vibration amplitude 10% of maximum vibration 60 mm vibration amplitude 20% of maximum vibration Effect of ultrasonication Particles obtained with ultrasonication 90 mm vibration amplitude 30% of maximum vibration 120 mm vibration amplitude 40% of maximum vibration Particle properties Particle size and size distribution tends to decrease as vibration amplitude increases Recovery yield was comparable to conventional spray drying methods Differential scanning calorimetry was performed to determine the crystalline state of particles fabricated using the SAS/ modified SASEM setup Encapsulation efficiency and in vitro release profile of the particles were determined EE% of as high as 80% were obtained 5000 90 4500 80 Encapsulatution efficiency (%) 70 3500 60 3000 (%) Particle size (nm) 4000 Recovery yield (%) 2500 50 2000 40 1500 30 1000 20 500 10 0 0 0 30 60 90 Ultrasonic vibration amplitude (micron) 120 0 30 60 90 Ultrasonic vibration amplitude (micron) 120 Differential scanning calorimetry analysis Thermogram analysis is an useful tool to determine whether paclitaxel is molecularly dispersed in the polymer matrix or phase separated as paclitaxel crystals DSC analysis Temperature range = 20 – 280 deg C Temperature ramp speed = 10 deg C/min Nitrogen flow rate = 5ml/min Literature values Pure paclitaxel PLLA Endothermic peak @ 223.0 deg C Melting point @ 172-178 deg C Thermogram properties 20 Raw paclitaxel 15 raw PLA (before SAS process) Exotherm (mW) 10 Paclitaxel loaded PLA with ultrasonication Blank PLA with ultrasonication 5 0 -5 -10 -15 -20 0 50 100 150 200 Temperature (oC) 250 300 In vitro release profiles Particles suspended in phosphate buffered saline (PBS) Placed in shaker bath (120 rpm, 37 deg C) Removed at predetermined time intervals Solution was centrifuged and buffer solution was removed Fresh PBS was added Paclitaxel content in PBS was extracted and analysed using HPLC 60 Cumulative release (%) 50 40 Paclitaxel loaded PLA samples obtained using modified SASEM process 30 Sample S1 S1 S2 S3 S4 20 S2 10 S3 0 0 5 10 15 20 25 Release time (days) 30 35 40 Ultrasonic vibration amplitude (mm) 0 30 60 90 Recovery Yield (%) Encapsulation efficiency (%) Size (nm) 21.1 18.1 14.6 12.8 70.0 ±3.5 67.7 ± 1.4 56.4 ± 14.4 83.5 ± 0.8 4130 ± 198 769 ± 210 506 ± 163 486 ± 134 Conclusions We have successfully fabricated micro and nanoparticles of PLA for potential application in controlled release purposes The effect of thermodynamic properties and hydrodynamics on particle formation was investigated in SAS process Varying the operating pressure from 73.8 bar (critical pressure) to 95 bar significantly alters the surface morphology of microparticles obtained Increasing liquid flowrate reduces particle size and size distribution The effect of ultrasonic vibration amplitude on particle size and properties was investigated Nanoparticles were obtained using the modified SASEM setup Particle size may be altered by applying different ultrasonic vibration amplitude Drug Delivery Devices Developed by Supercritical Fluid Technique A supercritical fluid is any substance at a temperature and pressure above its thermodynamic critical point. Supercritical fluids offer favourable gas-like transport properties and liquid-like solubility. Supercritical CO2 is used to fabricate biodegradable polymeric controlled release devices using Poly L lactide (PLA) and Poly DL lactide-co-glycolide (PLGA). CO2 was chosen as it has accessible critical temperature (31.1 deg C) and pressure (73.8 Bars), tunable properties near the critical region, is inexpensive, non-flammable, and generally environmentally benign. The supercritical fluid fabrication techniques employed in our research group include fabrication of microparticles using supercritical antisolvent (SAS) process, and the fabrication of micro-porous polymeric foams using supercritical gas foaming technique. In the supercritical60 bars antisolvent process, the jet disintegration process at near critical conditions was investigated. In vitro release profiles and other properties of the controlled release devices were also characterized. Phase diagram for carbon dioxide 70 bars 80 bars SEM images of different morphology particles obtained using SAS technique 80 Cumulative release (%) 70 60 50 40 30 S3A 20 S5A 10 S1A 0 0 5 10 15 20 Time (days) 25 30 35 Investigation of Various flow regimes of In vitro release of paclitaxel from PLA microparticles organic solution entering supercritical CO2 PLGA foams with different mean pore sizes achieved using Supercritical gas foaming technique The research efforts of our group are to develop controlled-release drug delivery devices using supercritical fluid techniques for chemotherapy to treat brain and liver cancers. Through investigation of the operating parameters of the SAS and Foaming process, controllable particle size with anticancer drug encapsulation and foams with tailored pore size have been achieved respectively. As such, the drug release profile may be modulated. Contact: Prof. Wang, Chi-Hwa Tel: 6516-5079 E-mail: chewch@nus.edu.sg