Polymer Synthesis CHEM 421 Inverse Emulsion Polymerization

advertisement

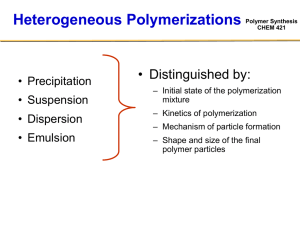

Emulsion Polymerization Polymer Synthesis CHEM 421 • External variable (surfactant concentration) used to increase BOTH molecular weight as well as rate of polymerization • Colloidal system easy to control –Thermal, viscosity issues • Reaction mixture in form of final product for coatings • Reaction product needs to be isolated from aqueous latex for many applications like rubber, elastomers, PVC, fluoropolymers (C8 issue), etc Variables and Other Characteristics Polymer Synthesis CHEM 421 • Redox Initiators – Hydrogen Peroxide w/ Ferrous Ion • Surfactant-Free Emulsion Polymerization – Initiator fragment affords amphiphilic character • Phase transfer catalysis (cyclodextran) • Microemulsion, Miniemulsion • Inverse emulsions • Core-Shell Particles • pH Control: Hollow Particles Various Emulsions Polymer Synthesis CHEM 421 • Emulsion Polymerization (macro) –Classic aqueous system –Particles range from 50-500 nm • Microemulsion Polymerization –Optically clear, smaller particles –No droplets, just micelles • Miniemulsion Polymerization –Between macro and micro systems, monomer droplets smaller than in macro systems Inverse Emulsion Polymerization Polymer Synthesis CHEM 421 • Standard emulsion polymerization uses water as the continuous phase, or oil-inwater (O/W) • Inverse emulsions use: –Oil as the continuous phase, or water-in-oil (W/O) –Hydrophilic monomer (or aqueous solution of monomer) dispersed in oil, i.e. xylene » Like acrylamide –Oil-soluble initiator –Surfactant Surfactants Polymer Synthesis CHEM 421 H2O Oil Surfactant Assemblies - Rich Morphologies Water 1% 2% 1% V VV- 2% 3% 4% R 3% V+L a Multi M 5% CTAT cationic surfactant 4% 5% SDBS 1% 2% 3% 4% anionic surfactant V Vesicles R Rod-like Micelles M Micelles Multi Multiphase Region V+La Vesicles and Lamellar Phase Controlled Radical Polymerization in Microemulsion Monomer-Swollen Micelles Monomer Diffusion M P• M M M M PM• Polymer Particle M M 1.0 0.6 [1]/[V50]=0 (RC1 data) [1]/[V50]=1.5 [1]/[V50]=2.25 [1]/[V50]=3.0 [1]/[V50]=4.5 [1]/[V50]=6.0 0.4 0.2 RI Response 0.8 Conversion (f) Microemulsion Nanoparticles [1]/[V50]=3.0 5.1% conversion Mn=2850, Mw/Mn=1.55 31.4% conversion Mn=6090, Mw/Mn=1.39 52.5% conversion Mn=9500, Mw/Mn=1.29 77.1% conversion Mn=12300, Mw/Mn=1.31 90.5% conversion Mn=16800, Mw/Mn=1.24 0.0 0 30 60 90 120 Time (mins) 150 180 4 8 12 16 Elution Time (mins) Liu, S. Y.; Kaler, E. W. et al. Macromolecules 2006, 39, 4345 Design of Polymeric Nanogels for DNA Delivery Polymer Synthesis CHEM 421 Research Objectives: 1. Design nanogels < 200 nm in diameter using inverse micro-emulsion techniques with excellent solution stability (w/o toxic solvents!) 2. Control release profile of DNA by selection of monomer and crosslinker composition and concentration 3. Attach targeting ligands to surface of nanogels Release of DNA Diffusion Pathway McAllister, K.; Sazani, P.; Adam, M.; Cho, M.; Rubinstein, M.; Samulski, R. J.; DeSimone*, J. M. J. Am. Chem. Soc. 2002, 15198-15207 Microemulsion Polymerization and Isolation of Nanogels Addition of Initiator to oil phase and free radical polymerization Step 1: Form microemulsion Polymer Synthesis CHEM 421 Removal of heptane and surfactant by extraction and dialysis Step 2: Polymerize microemulsion Step 3: Extract and purify nanogels Designing Polymeric Nanogels Monomers Nanogels O O O nO PEGdiacrylate n=8 O O OH 2-Hydroxyethylacrylate Cl - O O CH 3 + N CH 3 CH 3 2-Acryloxytrimethylammonium chloride Increasing Crosslinker Increasing Charge O Polymer Synthesis CHEM 421 + + + + + + + + + + ++ + + + + + + + + + + + + + + + + + + + + + ++ + + + + + + + + + + + + + Dynamic Light Scattering of Microemulsions Before and After Polymerization Polymer Synthesis CHEM 421 = 0% Cationic Monomer 100 Diameter (nm) = 12% Cationic Monomer = 25% Cationic Monomer 80 60 After Polymerization 40 Before Polymerization 20 0 0 10 20 30 40 50 60 Crosslinker Concentration (wt %) Before After Crosslinked Particles Adsorbed to SurfacePolymer Synthesis CHEM 421 Low Crosslinking High Crosslinking TEM Images of Nanogels 12% Crosslinker 50% Crosslinker 12% Charge 0% Charge 3% Crosslinker Polymer Synthesis CHEM 421 66K Magnification Samples Stained with 1% PTA Release of DNA from Non-ionic Nanogels Polymer Synthesis CHEM 421 Final Fluorescence Intensity in Bag Initial Fluorescence Intensity in Bag Dialysis for 24 hours at 37°C and at 4°C 37°C = 100% 4°C = 100% 37°C = 4% 4°C = 8% Variables and Other Characteristics • Lower temperatures –Anti-freeze • Redox initiators –Hydrogen peroxide w/ ferrous ion • Surfactant free –Initiator fragment results in amphiphilic character • Micro-emulsions, Mini-emulsions • Inverse emulsions • Core-shell particles Polymer Synthesis CHEM 421 Murthy N et al. PNAS 2003;100:4995-5000 Miniemulsion Polymerization for Dually-Triggered Degradable Nanogels Li, Z. C, et al. et al. J. Controlled Release 2011, 152, 57 Core-shell Polymer Particles Polymer Synthesis CHEM 421 General Practical Uses: • • • • • impact modification (soft core, hard shell) providing chemical reactivity to latex particles enhancement of adhesion properties (hard core, soft shell) controlled-release drug delivery (water-soluble core) prevent colors from showing through (hollow core) Morphology: core is determined by thermodynamic control (lowest surface free energy) and kinetic control. The second polymer doesn’t necessarily form the shell! shell Possible Morphologies Polymer Synthesis CHEM 421 Thermodynamically Stable Morphologies Core-shell Inverted core-shell Halfmoon A Halfmoon B Kinetically Trapped Morphologies Microdomains A B Raspberry 1st-stage polymer 2nd-stage polymer Sandwich A B Variables and Other Characteristics Polymer Synthesis CHEM 421 • Lower temperatures – Anti-freeze • Redox initiators – Hydrogen peroxide w/ ferrous ion • Surfactant free – Initiator fragment results in amphiphilic character • • • • Micro-emulsions, Mini-emulsions Inverse emulsions Core-shell particles pH Control – Hollow particles Hollow Particles & Ropaque™ Polymer Synthesis CHEM 421 Hollow particles in: paints, sunscreens, inks, cosmetics, fluorescent coatings, forgery- or counterfeiting-proof coated paper, paper products, etc. •Hollow polymer particles industrially important •Can replace use of TiO2 •Ropaque™ made by Rohm & Haas Lower pH Raise pH CH3 O O CH3 Kowalski, A.; Vogel, M. U.S. Patent 4,469,825. Blankenship, R.M.; Finch, W.C.; Mlynar, L.; Schultz, B.J. U.S. Patent 6,139,961. microvoid Hollow Particle Micrographs Polymer Synthesis CHEM 421 PMMA particles via W/O/W emulsion polymerization Core-shell hollow particles using methacrylic acid J. Poly. Sci. A: Polym. Chem., 2001, 39, 1435 Colloid Polym. Sci. 1999, 277, 252. Emulsion Polymerization for Dye-Labeled Nanoparticles Zhu, M. Q.; Li, A. D. Q. et al. J. Am. Chem. Soc. 2006, 128, 4303 PGMA macroCTA as a Steric Stabiliser for the Aqueous Dispersion Polymerisation of HPMA Y. T. Li and S. P. Armes, Angewandte Chem., 2010, 49, 4042 X = 30 65 O O O + HO O X = 100 PGMA 65 – PHPMA X HO HO PGMA PGMA 65 macroCTA 65 RAFT CTA HPMA HPMA X = 300 Targeting a longer core-forming block relative to the stabiliser block should lead to progressively larger sterically-stabilised nanolatexes? Scanning Electron Microscopy Studies Y. T. Li and S. P. Armes, Angewandte Chem., 2010, 49, 4042 105 nm PGMA65-PHPMA300 latex 90 nm PGMA65-PHPMA200 latex SEM images confirm spherical, near-monodisperse latexes Transmission Electron Microscopy Studies Y. T. Li and S. P. Armes, Angewandte Chem., 2010, 49, 4042 PGMA65-PHPMA50 PGMA65-PHPMA70 200 nm 200 nm Dh = 29 nm Dh = 40 nm Negative staining using uranyl formate: Prof. S. Sugihara and Dr. A. Blanazs PGMA65-PHPMA100 200 nm Dh = 58 nm Scale bar: 100 nm DMF GPC Studies of PGMA-PHPMA Block Copolymers A. Blanazs, S. P. Armes, A. J. Ryan et al., J. Am. Chem. Soc. 2011, ASAP Aldrich-sourced HPMA has only 0.10 mol % dimethacrylate impurity Best result: Mw/Mn < 1.20 for G47-H1000 at 99 % conv. (within 2 h at 70oC) ! So excellent control over MWD and good CTA blocking efficiencies…. A. Blanazs, Armes, 77.5 min = 68S. %,P.DP 131 J. Madsen, A. J. Ryan and G. Battaglia JACS, 2011, ASAP More In Situ Studies: PGMA47-PHPMAx 84 mins = 75 %, DP 150 Scale bars: 200 nm 87 mins = 78 % DP 156 75 min = 62 %, DP 123 90 mins = 82 %, DP 164 65 min = 46 %, DP 92 225 mins = 100 % DP 200