M 1

• Odian Book

Chapter 6-2

Polymer Synthesis

CHEM 421

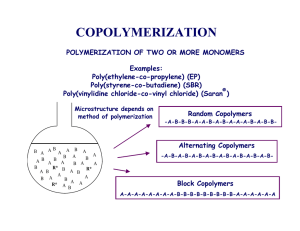

Copolymers

Polymer Synthesis

CHEM 421

• Copolymers involve the use of two or more monomers

• Copolymers allow us to tailor product properties

– Tg

– Tm

• Commercially important (chain growth) examples include:

– Styrenics

» Styrene/acrylonitrile (SAN): increased impact resistance and solvent resistance; 10-40% AN, Samsonite luggage

» Styrene/butadiene (SBR): 25% styrene/75% butadiene

» Largest volume synthetic rubber (tires)

» HIPS: High Impact PS (PBD-g-PS)

» Styrene Maleic Anhydride (SMA)

Copolymers

Polymer Synthesis

CHEM 421

• Commercially important copolymers (Cont’d)

–Vinyl chloride

» Rigid PVC: ca. 5% vinyl acetate, lowers Tg small amount allow to be processed a lower temperatures avoiding degradation

» Flexible: 20-40% vinyl acetate (tubing, sheets (e.g. shower curtains, etc.)

» Packaging: Saran Wrap® (90% vinylidene chloride)

Copolymers

• Commercially important copolymers (Cont’d)

– Ethylene (> 10 billion lbs/yr)

» LDPE (homopolymer!)

» High pressure free radical

» 30-40% x-tallinity

» HDPE (homopolymer!)

» Ziegler-Natta

» 75% x-tallinity

» Linear Low Density Polyethylene

» Linear copolymer with 1-5 mol% α-olefins

» EVA: Ethylene vinyl acetate: 2-40% vinyl acetate

» Packaging, molding

» EPR: Ethylene-propylene rubber (plus cure site monomer)

» Ethylene/acrylic acid: (1-10 mol% AA); ionomer

» Surlyn®

Polymer Synthesis

CHEM 421

Copolymers

Polymer Synthesis

CHEM 421

• Commercially important copolymers (Cont’d)

–Fluoropolymers

» PTFE: T m

= 335 °C, T g

= -70 °C

» PVDF: T m

= 180 °C

» FEP: T m

= 250 - 280 °C, T g

= 70 - 120 °C

» ETFE: T m

= 225 °C, T g

= 145 °C

» PFA: T m

= 300 °C

» Teflon AF:

» Nafion:

Copolymerization Kinetics

Polymer Synthesis

CHEM 421

Homo-propagation

Cross-propagation

Terminal Model

Copolymerization Kinetics

Polymer Synthesis

CHEM 421

Penultimate Model

Copolymerization Kinetics

Polymer Synthesis

CHEM 421

Terminal Model

Homo-propagation

Cross-propagation

Cross-propagation

Homo-propagation

Copolymerization Kinetics

Polymer Synthesis

CHEM 421

R p11

= k

11

[M

1

•] [M

1

]

R p12

= k

12

[M

1

•] [M

2

]

R p21

= k

21

[M

2

•] [M

1

]

R p22

= k

22

[M

2

•] [M

2

]

Terminal Model

Copolymerization Kinetics

Polymer Synthesis

CHEM 421

The rate of disappearance of M

1 and M

2 can be expressed as: d [M

1

]

——— = k

11 dt

[M

1

•] [M

1

] + k

21

[M

2

•] [M

1

] d [M

2

]

——— = k dt

12

[M

1

•] [M

2

] + k

22

[M

2

•] [M

2

]

Copolymerization Kinetics

The ratio of the two rates is then: d [M

1

] k

11

[M

1

•] [M

1

] + k [M

2

•] [M

1

] d [M

2

] k

12

[M

1

•] [M

2

] + k

22

[M

2

•] [M

2

]

Polymer Synthesis

CHEM 421

Simplify: d [M d [M

1

2

] [M

[M

1

2

] k

] k

11

12

[M

[M

1

1

•] + k

•] + k

21

22

[M

[M

2

2

•]

——— = ——— ——————————

] •]

Copolymerization Kinetics

Polymer Synthesis

CHEM 421

Assume the Steady State Approximation:

The concentrations of M

1

• and M

2

• are constant

Therefore:

The rate of addition of M

1

The rate of addition of M

2

• to M

2

• to M

1 will equal k

12

[M

1

•] [M

2

] = k

21

[M

2

•] [M

1

]

Define: r

1

= k

——— k

12 r

2

= k

——— k

21

Copolymerization Kinetics

Copolymer Composition Equation:

Polymer Synthesis

CHEM 421 d [M d [M

1

2

] [M

[M

1

2

] r

1

] [M

[M

1

1

] + [M

] + r

2

[M

2

2

]

——— = ——— ———————

] ]

Molar ratio of the monomers in the copolymer

Copolymerization Kinetics

Copolymer Composition Equation: f

1

= 1 – f

2

= —————

[M

1

[M

1

]

] + [M

2

]

Polymer Synthesis

CHEM 421

F

1

= 1 – F

2 d[M

= ——————— d[M

1

1

]

] + d [M

2

]

F

1

= r

1 f 2 +

—————————— r

1 f

1

2 + 2 f

1 f

2 f f

+

2 r

2 f

2

2

Copolymerization Examples

Polymer Synthesis

CHEM 421

• r

1

= r

2

= 1.0

–Monomers exhibit no preference for homo-propagation vs cross-propagation

–Truly random copolymer results

1.0

0.8

–F

1

= f

1

–Ethylene / vinyl acetate

F

1

0.6

0.4

0.2

0.0

A

0.0 0.2 0.4 0.6 0.8 1.0

f

1

Copolymerization Examples

Polymer Synthesis

CHEM 421

• r

1

• r

1

= r

2

= 1.0

= r

2

= 0.0

– Monomers exhibit tendency to cross-propagate

1.0

– Alternating copolymer results

0.8

0.6

– F

1

= 0.5

– Styrene / maleic anhydride

F

1

0.4

0.2

B

– TFE / ethylene

– 1-Butene / sulfur dioxide

0.0

A

0.0 0.2 0.4 0.6 0.8 1.0

f

1

Copolymerization Examples

Polymer Synthesis

CHEM 421

•

• r

1 r

1

= r

2

= r

2

= 1.0

= 0.0

• r

1 and r

2 between 0 and 1.0

1.0

– Common

– Cross-over point

» Azeotropic polymerization

F

1

0.8

0.6

0.4

C

B

0.2

0.0

A

0.0 0.2 0.4 0.6 0.8 1.0

f

1

Copolymerization Examples

Polymer Synthesis

CHEM 421

•

• r

1 r

1

= r

2

= r

2

= 1.0

= 0.0

• r

1 and r

2 between 0 and 1.0

1.0

• r

1

>> 1.0 and r

2

<< 1.0

– Significant drift in feed ratio

F

1

0.8

0.6

0.4

C

D

B

0.2

0.0

A

0.0 0.2 0.4 0.6 0.8 1.0

f

1