Polymers

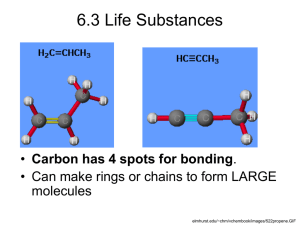

advertisement

1 Hydrocarbon Molecules Unsaturated: Double and triple bonds eg., CnH2n CnH2n-2 Ethylene Acethylene CH2=CH2 CHCH C2 H 4 C2 H 2 Chapter 14: Polymer Structures 2 Hydrocarbon Molecules Saturated: single bonds eg., CH4,C2H6, C3H8 CnH2n+2 Isomerism: n-butane Straight chain Chapter 14: Polymer Structures Isobutane Branched chain 3 Hydrocarbon Molecules R-COOH R-CHO R-C 6 H 5 Source: William Callister 7th edition, chapter 14, page 493, table 14.2 Chapter 14: Polymer Structures 4 Polymer Molecules Gigantic: Macromolecules Monomer: One unit Polymer Many units eg., one unit Chapter 14: Polymer Structures 5 Polymer Molecules continue… PTFE: TEFLON Polytetrafluoro ethylene Mer Chapter 14: Polymer Structures 6 Polymer Molecules continue… PVC: Vinyl Polyvinyl chloride Mer Polypropylene: Mer Chapter 14: Polymer Structures 7 Polymer molecules Homopolymer: Repeating units of the chain are of the same type Co-polymer: Two or more different mer units. Chapter 14: Polymer Structures 8 Polymer molecules continue Bifunctional: Two (2) active bonds Trifunctional: Three (3) active bonds Chapter 14: Polymer Structures 9 Molecular weight •Large macromolecules synthesized from molecules •Not all polymer chains grow to the same length •Average molecular weight is determined by measuring viscosity and osmotic pressure •The chain is divided into size ranges •No. of moles (or fraction) of each size range is determined Chapter 14: Polymer Structures 10 Molecular weight continue… Number average molecular weight, M n =xiMi Where Mi=Mean molecular weight within a size range xi=Fraction of number of chains within the corresponding (same) size range Chapter 14: Polymer Structures 11 Molecular weight continue… Weight Average Molecular weight, M w =wiMi Where, Mi=Mean molecular weight within a size range wi=weight fraction of molecules within the same size range Chapter 14: Polymer Structures 12 Molecular weight continue… Notice the shift Source: William Callister 7th edition, chapter 14, page 498, figure 14.3 Chapter 14: Polymer Structures 13 Molecular weight continue… Source: William Callister 7th edition, chapter 14, page 498, figure 14.4 Chapter 14: Polymer Structures 14 Molecular weight continue… Degree of polymerization (n): n= Average no of mer units in a chain nn=Number average degree of polymerization nw=Weight average degree of polymerization Mn nn m m Mer molecular weight Mw nw m Chapter 14: Polymer Structures 15 Molecular weight continue… For a copolymer (i.e., two or more mer units), m f j m j Where, fj= chain fraction of mer mj=molecular weight of mer Chapter 14: Polymer Structures 16 Problem 14.1: Computations of Average Molecular Weights and Degree of Polymerization Assume that the molecular weight distributions shown in Figure 14.3 are for poly(vinyl chloride). For this material, compute: (a) the number-average molecular weight, (b) the degree of polymerization, and (c) the weight-average molecular weight. Chapter 14: Polymer Structures 17 Problem 14.1: continue… xiMi=21,150 Where, xi: Fraction of total no. of chain within the corresponding size change M n : Number average molecular weight Chapter 14: Polymer Structures 18 Problem 14.1: continue… xiMi=23,200 Where, M w : weight average molecular weight Chapter 14: Polymer Structures 19 Problem 14.1: continue… PVC: C2H3Cl C Atomic weight (g/mol) 12.01 H Cl 1.01 35.45 m 2(12.01) 3(1.01) 35.45 m 62.50g/mol Chapter 14: Polymer Structures 20 Problem 14.1: continue… Number average degree of polymerization, M n 21 ,150 nn 338 m 62.50 Chapter 14: Polymer Structures 21 Molecular weight of polymers •Melting point increases with molecular weight (for M up to 100,000 g/mol). i.e. increased intermolecular forces •Long chain increased bonding between molecules. (Van der Waals or hydrogen bond) •At room temperature, Short chains: Molecular weight: 100 g/mol – liquids/gases (1000 g/mol: waxes, soft resins) High polymers: 10,000 to several million g/mol – solids Chapter 14: Polymer Structures 22 Molecular shape •Single chain bonds can rotate like a cone/bend in three dimensions •Bends, twists, kinks, in single chain molecules CC: rigid (rotationally) bulky or large side group: restricted rotation Benzene ring: restricted rotation Chapter 14: Polymer Structures 23 Molecular structure Linear Mer units end-to-end in chains Source: William Callister 7th edition, chapter 14, page 502, figure 14.7(a) e.g., Polyethylene Chapter 14: Polymer Structures PVC 24 Molecular structure continue…. Polystyrene PMMA Poly(methyl methacrylate) Chapter 14: Polymer Structures 25 Molecular structure continue…. Branched Polymers •Side-branch chains •Less packing efficiency; lower density Source: William Callister 7th edition, chapter 14, page 502, figure 14.7 (b) Chapter 14: Polymer Structures 26 Molecular structure continue…. Cross-linked Polymers •Formed by non-reversible chemical reaction •Additives covalently bonded to chains e.g., sulfur in vulcanizing Source: William Callister 7th edition, chapter 14, page 502, figure 14.7 (c) Chapter 14: Polymer Structures 27 Molecular structure continue…. Net-work polymer •Three active covalent bonds •Highly cross-linked Source: William Callister 7th edition, chapter 14, page 502, figure 14.7 (d) Chapter 14: Polymer Structures 28 Molecular configurations Head-to-tail configuration Bonded to alternate carbons on the same side Source: William Callister 7th edition, chapter 14, page 503 Where, R: Alkyl radical Chapter 14: Polymer Structures 29 Molecular configurations continue…. Head-to-head configuration Bonded to adjacent carbon atoms Source: William Callister 7th edition, chapter 14, page 503 Chapter 14: Polymer Structures 30 Molecular configurations continue…. Stereoisomerism Isotactic configuration R groups are situated on the same side of the chain Source: William Callister 7th edition, chapter 14, page 504 Chapter 14: Polymer Structures 31 Molecular configurations continue…. Syndiotactic On alternate sides Source: William Callister 7th edition, chapter 14, page 504 Chapter 14: Polymer Structures 32 Molecular configurations continue…. Atactic At random position Source: William Callister 7th edition, chapter 14, page 504 Conversion from to another is only by severing branches and through new reaction Chapter 14: Polymer Structures 33 Molecular configurations continue…. Geometric Isomerism CIS-Isoprene eg., Natural rubber Attacked by acids/alkalis TRANS-Isoprene eg., Gutta Percha Highly resistant to acid/alkalis Chapter 14: Polymer Structures 34 Molecular configurations continue…. Geometric Isomerism continue… TRANS- isoprene e.g., Gutta Percha –Highly resistant to acids/alkalis Chapter 14: Polymer Structures 35 Molecular configurations continue…. Chapter 14: Polymer Structures Source: William Callister 7th edition, chapter 14, page 506, figure 14.8 36 Copolymers (different types of mers) Random Source: William Callister 7th edition, chapter 14, page 508, figure 14.9(a) Alternate Source: William Callister 7th edition, chapter 14, page 508, figure 14.9(b) Chapter 14: Polymer Structures 37 Copolymers continue… Block Source: William Callister 7th edition, chapter 14, page 508, figure 14.9(c) Styrene butadiene rubber (SBR), (Random copolymer): Automobile tires. Nitrile butadiene rubber (NBR), Random copolymer): Gasoline hose Chapter 14: Polymer Structures 38 Polymer Crystallinity Crystallinity: Packing of chains to produce ordered atomic array. Crystalline Crystalline + or noncrystalline noncrystalline Total Chapter 14: Polymer Structures 39 Polymer Crystallinity continue… ρ c (ρ s ρ a ) %Crystalli nity 100 ρ s (ρ c ρ a ) Where, s=Density of specimen a=Density of totally amorphous polymer c=Density of perfectly crystalline polymer Chapter 14: Polymer Structures 40 Polymer Crystallinity continue… Crystallinity characteristics •Degree of crystallinity depends on rate of cooling; need sufficient time to result in ordered configuration. •Amorphous (No crystallinity) if chemically complex microstructure. Crystalline if chemically simple polymer. e.g., polyethylene, PTFE, even if rapidly cooled Chapter 14: Polymer Structures 41 Polymer Crystallinity continue… •Amorphous if network polymer. Crystalline if linear polymer (no restrictions to prevent chain alignment) •Amorphous: Atactic stereoisomer. Crystalline: Isotactic or Syndiotactic stereoisomer •Amorphous: If bulky/large side-bonded group. Crystalline: Simple straight chain Chapter 14: Polymer Structures 42 Polymer Crystallinity continue… •Amorphous: Most copolymers (and more irregular/ random mers) Crystalline: Alternating or block polymers •Amorphous: Random or graft polymers •Crystalline: Strong, more resistant to dissolution by softening by heat Chapter 14: Polymer Structures 43 Polymer crystals Fringed micelle model •Aligned small crystalline regions (crystallites or micelles) •Amorphous regions in-between platelets of crystals (1020 nm thick) (10m long) Chapter 14: Polymer Structures 44 Polymer crystals continue… Fringed micelle model continue… So, multilayered structure Chain-fold model: amorphous molecular chains within platelets; back and forth Chapter 14: Polymer Structures 45 Polymer crystals continue… Spherulite model •Bulk polymers solidify as small spheres (Spherulites) •Within each such sphere, folded crystallites (lamellae), ~10 nm thick form •Adjacent spherulites impinge on each other forming planar boundaries e.g., Polyethylene, Polypropylene, PVC, PTFE, Nylon Chapter 14: Polymer Structures 46 Polymers: summary •Large molecules of polymers •Mers, homopolymers, copolymers •Molecular weight –Number-Average –Weight-Average Chapter 14: Polymer Structures 47 Polymers: summary continue… •Isomerism Isotactic Syndiotactic Atactic •Crystallinity: Degree of crystallinity •Polymer crystals Chapter 14: Polymer Structures 48 Thermosetting and Thermoplastic Polymers Determined by mechanical behavior upon heating to high temperatures Thermosetting Thermoplastic •Thermosets •Thermoplasts Become permanently hard Soften upon heating; upon heating. Do not harden upon cooling. It is soften upon subsequent reversible heating Fabricated by applying heat and pressure Chapter 14: Polymer Structures 49 Thermosetting and Thermoplastic Polymers continue… Thermosetting Initial Heating: Covalent crosslink form and link adjacent molecular chains. Chains are anchored; no vibrational or rotational chain motions, 10-50% of chain mer units are crosslinked Chapter 14: Polymer Structures Thermoplastic As Temperature is increased Secondary bonds break (due to molecular motion). So when stress is applied, adjacent chains move 50 Thermosetting and Thermoplastic Polymers continue… Thermosetting Further heating: Severance (breaking) of crosslink bonds and polymer degradation Chapter 14: Polymer Structures Thermoplastic Irreversible degradation upon further heating: Violent molecular vibrations break primary covalent bonds 51 Thermosetting and Thermoplastic Polymers continue… Thermosetting Thermoset polymers are harder, stronger and brittle Better dimensional stability e.g., Cross linked and network polymers Vulcanized rubbers, epoxies and phenolic and some polyester resins Chapter 14: Polymer Structures Thermoplastic Soft and Ductile Most linear polymers and polymers with branched structures with flexible chains 52