Healthcare Supply Chain: Dynamics & Optimization

advertisement

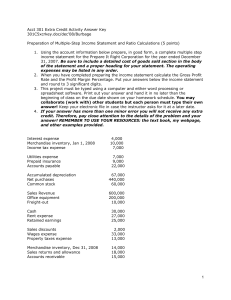

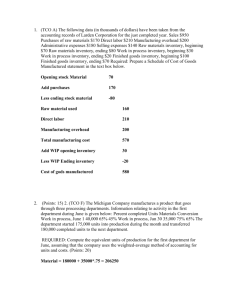

Owens & Minor Market dynamics and the developing trends. What is the Supply Chain continuum? How to baseline & the benefits of moving towards best practice. Supply Chain as an Evolving Model. • Health reform impact on Supply Chain? Model of the Future • Future of Supply Chain? • External ways to increase efficiencies in our organizations? Proactive Supply Chains • How to improve quality and reduce costs? Aggregation • Optimize the different distribution channels? 2 Market forces are accelerating industry-wide change: ◦ Future driven by Payors and payment structure ◦ Margin pressures increasing significantly across all trading partners ◦ Competitive lines are blurring 3 Supply Savings Supply Savings - Transportation - Physician Clinics/ Supply Savings Non-Acute Labor Activity Savings Labor Activity Savings Labor Activity Savings - Bill-Only (Implant) - Clinical Inventory Management - JIT to the OR - JIT / Totes - Par Optimization - 3PL model - Bulk - Pallet Architecture - Cross Docking Joint/Self Contracting Integrated Service Center ISC 6 How to Baseline How to Baseline Executive Scorecard - Summary Descriptions FTEs Wages & Benefits Overtime & Benefits Wages, OT & Benefits Inventory Investment Cost of Capital Inventory Shrinkage Inventory Carrying Cost Freight Expense Additional Expense (AOP Par Ex) Facility Expense Other Facility, equipment Base 33.00 $1,639,145 $5,150 Proposed 20.80 $1,032,850 1,725 $438,185 $200,000 $71,400 $1,363,250 $337,000 $4,373,738 $3,444,409 ($929,329) $1,644,295 $7,166,972 $430,018 $179,174 Total Expense Distribution Cost Plus Activity Fee Other Distribu.- Cost Plus Other Distributors' - Fees Distribution Expense $609,193 $420,000 $0 $1,363,250 $337,000 Impact (12.20) Expense ($606,295) (3,426) ($609,721) ($1,324,510) ($79,471) (91,537) (171,008) (220,000) 71,400 0 0 Expense Expense $1,034,574 $5,842,462 $350,548 $87,637 $475,000 $0 $128,250 $0 $660,000 $110,000 $228,250 $0 $185,000 110,000 100,000 0 603,250 998,250 395,000 Fully loaded customer & distributor costs $4,976,988 $4,442,659 ($534,329) One-Time Inventory Savings $7,166,972 $5,842,462 ($1,324,510 ) Ongoing process savings $4,976,988 $4,442,659 ($534,329) Goal Why Transform from a reactive supply chain to• a Reduced supply spend proactive demand chain • Optimized labor Supply Chain Adjust Patient • Elimination of inventory Demand • Chain Improved profitability per procedure Schedule Use Assemble Preference Card 11 Supply Mode of Distributor Model • • • • High volume <$800/unit Low complexity Nearly 100% - GPO contracting • Uncomplicated use • Private label • Minimal direct sales Purchase 35% 65% Manufacturer Direct • Low to moderate volume • >$800/unit • High to very high complexity • Direct sales force • High prevalence of local contracting • Complicated use • Mostly sold direct By volume: 75% Distribution / 25% Direct 2012 O&M research, estimates AHA, Gartner Research, 2011 12 Distributor Model + Fee for Service • Manufacturers increased reliance on more effective supply chains to service providers • Increase Flexibility 2013-2015 • Downward pressure on revenues /margins forces re-evaluation of SG&A 40% 60% • Lower Cost • Improve Visibility 2012 O&M research, estimates Manufacturer Direct AHA, Gartner Research, 2011 inventory & DSO elements • Address changing customer needs • Health reform impact on distribution? • Future of distribution? • External ways to increase efficiencies in our organizations? • How to improve quality and reduce costs? • Optimize the different distribution channels? Identify logistics service partners; separate out manufacturers/wholesalers Invest in technology & interfaces to connect schedule, care & replenishment Eliminate ownership as a condition of management; consider novel investments 13