The Impact of CAD and CAM on Manufacturing

advertisement

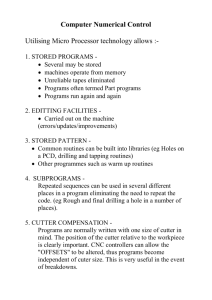

Option C: CAD/CAM C3 – THE IMPACT OF CAD/CAM ON MANUFACTURING Numerical Control Automated machines that require data to be inputted manually by a trained operator Explain how a numerically controlled (NC) machine aids manufacturing. An NC machine is able to reproduce manufactured parts in large quantities NC machines can be used reliably in situations requiring continuous operation in areas that would normally expose operators to hazardous conditions. Computer Numerical Control (CNC). Refers specifically to the Each code is assigned to computer control of machines for the purpose of manufacturing complex parts in metals and other materials. Machines are controlled by a program commonly called a “G code”. a particular operation or process. The codes control X,Y,Z movements and feed speeds. Compare numerical control and computer numerical control. Numerical control machines are not connected to a computer. An operator inputs the data manually. A CNC machine accepts and operates from computer data. A CNC machine offers great flexibility over that of NC. Products are made accurately. CNC machines are economical to operate, but initial costs are high. Explain how a CNC machine further aids manufacture. Global communication systems allow for the CNC machining data to be sent anywhere in the world. The flexibility of a CNC machine reduces downtime between batch runs or one-off production. CNC machines can be incorporated into a CIM (computer integrated manufacturing) environment to control individual requirements and consumer needs. Greater flexibility Reprogrammability Multi-machine control Tooling Multi-axis machining Describe two- and three-axis machining processes. Two-axis CNC lathe: workpiece motion (rotary axis) X,Y axes for cutting. Three-axis machining for milling, routing and engraving: Z axis for depth of cut X and Y axes for direction of cut. Describe four- and five-axis machining processes. Four-axis machining is a Five-axis machining is a lathe with a milling head attachment; X,Y,Z axes plus an additional rotary motion. milling machine with three linear axes (X,Y,Z) with rotation about two axes. Milling machines and routers can be interfaced in a CAD/CAM system. Issues faced by the designer and manufacturer when choosing CNC equipment. Costs Flexibility Maintenance Tooling Training, Speed and quality of finish. Outline how a CNC lathe is interfaced in a CAD/CAM system to produce a 3D model. Consider a suitable product to be made on a lathe and outline the advantages and disadvantages to the operator. Computer Integrated Manufacture (CIM). A system of manufacturing that uses computers to integrate the processing of production, business and manufacturing in order to create more efficient production lines. Describe how CAD/CAM can be integrated into a CIM system. One example of a CIM system. For example, car production. Vehicle ordered to customer specification. Materials and third-party parts ordered to allow JIT (just-intime) manufacture. Assembly checked for quality throughout, allowing for minimal wastage. Discuss the advantages and disadvantages of CIM to consumers and manufacturers. Manufacturer: Initial set-up costs Staff morale Storage and reduction of waste. Customer Cost-effective product Quality Individual needs.