Platform downstream processes in the age of continuous

advertisement

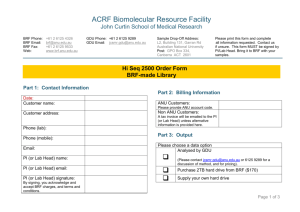

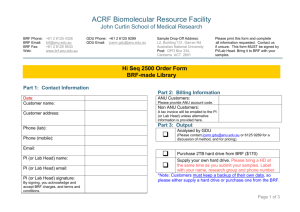

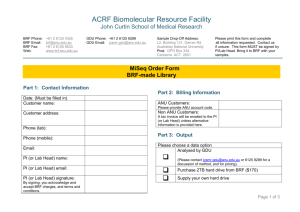

Platform downstream processes in the age of continuous chromatography: A case study Mark Brower BioProcess Technology & Expression Bioprocess Development Kenilworth, NJ Integrated Continuous Biomanufacturing Castelldefels, Spain 20-24 October 2013 Transition to Future Concepts To meet increasing global demands requires… PROCESS INTENSIFICATION Batch Stainless Batch Stainless / Single Use Continuous Single Use Enabled Next Generation Bulk mAb Downstream Purification Primary Recovery (Centrifugation / MF + DF) Bulk Purification Protein A Chromatography 6H 12H 18H Viral Inactivation (Low pH Hold) 24H Fine DNA / HCP / Viral Adsorption Anion Exchange Chromatography Variant and Aggregate Clearance Cation Exchange Chromatography Formulation Viral Filtration Nanofiltration Concentration / Buffer Exchange Microfiltration / Diafiltration 30H • Increased flexibility 36H • Reduced footprint 42H • Reduced capital spend 48H • Better resource utilization 54H Bioburden Reduction Sterile Filtration 60H Continuous Processing Vision - 2,000L SUB* Formulation: BRF/DiaF Anion Exchange Membrane Continuous UF A E X M Surge Bag S U B* BRF p Viral Filtration Continuous Viral Inactivation Single-Use Centrifugation p Surge Bag Surge Bag Surge Bag p *Single-Use Bioreactor Depth /BRF Filtration p Surge Bag p p p BRF BioSMB Protein A Overall DSP Time Cycle is Dictated by the Longest Step Other Steps are Lengthened to Compensate p BRF Polishing Step Continuous Processing Case Study mAb 1 - Non-platform Hour 0 kSep 9:00 DF/SF 9:30 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 7:15 12:00 SMB 11:00 VI 11:40 12:15 1:30 AEX 6:00 4:00 MMC 7:30 UF 4:15 9:00 5:00 AEX Membrane SMB Protein A SU Centrifuge Harvest Bag SPTFF SUB DF / BRF Viral Inactivation Mixed Mode MCC for Bind & Elute Applications C1 • Methods based on batch process C7 C5 • Flexibility in loading zone C3 • Loading, washing, elution, CIP carried out simultaneously Switch Time CEX CMCC Load Zone Design Feed nd 2 Pass W1 Longer residence time in the elution zone Similar column cycling compared with protein A Productivity 3.7X batch process Feed 2 methods designed to maximize time in the elution zone Wash 1 in parallel 8 columns (shorter / continuous feed) Wash 1 in series 6 columns (longer / discontinuous feed) W1 nd 2 Pass SMB Transformation of Platform CEX Step 3.7 x Specific Productivity Design Equations* 1 1 1 1 CE 1 - exp - NT U 1 - 1 1 exp - NT U 1 - S S S S S QBed qBed Q feed c0 NTU koLa N V Ni V N2 V koLa 1 Qi Q feed Q feed QW 1 • 1.2cm x 3cm pre-packed columns • Poros HS Adsorbent • qbatch=50mg/mL • Feed = 11-13g/L • 2 different load zone configurations • Good agreement between experimental and theoretical capture efficiency • CMCC loading was 60-73mg/mL at high yield *Miyauchi and Vermeulen (1963) >95% Aggregate Clearance – Wash in Series Configuration • Effect of column height investigated • 1.2 x 3.4cm, 1.2 x 6.8cm, 0.5 x 20cm • Feed aggregation varied (low and high) • Six 1.2 x 3.4cm columns for MCC • 4th cycle fractionation (20 fractions per column pooled) 10% 20cm High Agg 20cm Low Agg 6.8cm Low Agg CMCC 3.4cm Low Agg % Aggregates 8% • Similar pre-peak observed in batch and MCC Process • Similar pool aggregate levels observed 6% 4% • Little difference observed at different column heights 2% 0% 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Normalized Elution Volume [-] 0.8 0.9 1.0 Integration of MCC CEX into Continuous DSP - 100L platform harvest Formulation: BRF/DiaF pH UF Continuous A E X M 100% S U B* pH Concentration Factor [-] 80% 60% 40% 20% BRF 0% -20% -40% -60% -80% VI Feed -100% 0 200 0 400 20 AEX Feed VI CEX Feed 40600 60 800 80 1000100 1200 120 1400 140 Time [Min] 2 Membrane Loading [L/m ] Surge Bag Surge Bag p Depth /BRF Filtration p Surge Bag p Continuous UF Surge Bag p Viral Filtration p Surge Bag p p BRF C R I T I C A L I T Y BioSMB Protein A p BRF BioSMB CEX 1.5 1.5 1.25 1.25 1 1 0.75 0.75 0.5 0.5 0.25 0.25 0 0 0 1 2 3 4 Column • 16 Overlaid CEX Elution Profiles • AEXM Effluent Feed 50 6 0.5 Absorbance [mAU] Absorbance [mAU] Continuous CEX Performance 0.4 0.3 0.2 0.1 STDEV(%) Between Columns =1.01% 0 1 Continuous Processing Case Study mAb 2 - Platform Centrifugation DF/BRF Protein A SMB Viral Inactivation Anion Exchange Membrane Cation Exchange Chromatography SPTFF Overall Mass Balance = 93% Average Yield 97.3% 98.6% 98.1% 100% DNA* [ppm] N/S 30,515 N/S 2 HCP [ppm] N/S 383,300 N/S 1,063 Res. ProA [ppm] N/S N/S N/S 2.1 98.8% <LOQ 82 1.5 99.0% 84.2% <LOQ 605 <LOQ 99.2% 99.5% 0.001 35 <LOQ 99.0% 77.9% 0.001 8.7 <LOQ 99.0% % Monomer N/S N/S N/S 89.8% DSP Productivity Enhancement Step Continuous Protein A Chromatography [g/(L·h)] 3.1 Cation Exchange Chromatography [g/(L·h)] 3.7 Overall [g/day] ~3x • MCC steps enjoy a modest specific productivity increase • Other steps suffer from lower specific productivities because they are slowed to accommodate the incoming flow rate • The overall DSP will be 2-4x more productive (g/day) by operating in parallel (dependent on Protein A column sizing) Conclusions and Future Work • A platform cation exchange step was transformed into a MCC process – 3.6X specific productivity increase – Maintained consistent aggregate separation performance compared to the batch process – Integrated into continuous DSP top reflect platform operation with 84% yield at the 100L scale – Matched cycles with protein A step • Interface CEX step with continuous viral filtration • Scale up process to 2000L in 24hours Acknowledgements • • • • BTE – Marc Bisschops – Ying Hou – Steve Allen – David Pollard Analytical Support – Joe Fantuzzo – John Troisi – Jun Heo Fermentation Support – Patty Rose – Chris Kistler – Rachel Bareither Protein Purification Process Development – Nihal Tugcu – Thomas Linden Questions?