SRC_talk_3

advertisement

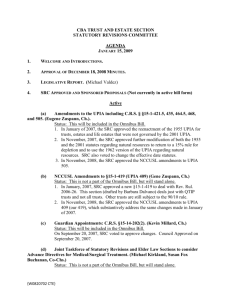

System for Radiographic Control for security SRC “Sibscan” S.Baru Budker Institute of Nuclear Physics, Novosibirsk, Russia 1 The device is designed for security personal inspection for the purpose of detection of dangerous items and weapons hidden on body or in clothes. Unlike inspecting for metal items, radiographic inspection is the only way to inspect for plastic explosive materials and weapons. These devices can be used at airports, customs, prisons, embassies, nuclear power centers, banks etc. 2 Such systems must meet the following requirements: a) possibility of low-contrast objects detection, allowing to observe them both near human body (inside clothes, at the side), against background of the most dense body parts (abdominal cavity) and inside body also; b) ultra-low doses of x-ray irradiation, comparable with background dose; c) large image dimensions (more than human height and width); d) short period of inspection; e) presence of software allowing to analyze an image in a short time; f) minimum inconveniences for inspected person; g) high capacity. 3 Schematic sketch of a two-coordinate method: 1 – X-ray tube; 2 – Two-coordinate detector Schematic sketch of a scanning method: 1 – collimator; 2 – linear detector 4 Additional requirements: The system shouldn’t have the visible moving parts. The system operation should be noiseless. The system should have only the minimum of distortion to make searching of hidden things easier. The system components should be very stable against irradiation because its productivity can be very high ( 100 persons per hour without any interruption). Dynamic range should be very large (>400) because we will search the hidden objects inside the body and at edges of clothes. 5 side view view from above Schematic sketch of SRC Such system can be created only applying scanning method to obtain an image. The basic elements of the system are: irradiator with X-ray tube, collimator and X-ray detector. The slit collimator cuts flat fanshaped X-ray beam, which is recorded by detector after passing through the inspected person. During inspection the tube, the collimator and the detector move vertically. Detector data of irradiation distribution along one image “line” are stored to memory every several ms. On scanning completion the whole picture is transferred to computer and after quick processing image appears on display. 6 First sample of SRC at the time of testing on the manufacturing plant 7 Basic SRC parameters: Maximum scanning height Image width Channel size (resolution) Scanning speed Maximum scanning time Capacity Radiation dose per 1 inspection - 2000 mm - 800 mm - 1x1 mm - 40 cm/s -5s - 2 persons/min ~1,0 μSv * *This dose is equivalent to 10 minutes of flight background dose. 8 Two licenses for SRC production are sold to Japanese and Korean companies. The first sample of Russian SRC was manufactured at the end of 2004 and works now in Moscow airport Domodedovo. SRC has all permission documents and protected by patent. 9 There are several systems with the same purpose: Conpass (Belarus), Scannex (South African Republic), Secure 1000, Secure 2000 (USA). 10 The international inspection. It is performed by Norman Shanks (on the left) the official European expert in the field of aviation security. 11 Final of inspection. Photo for memory. 12 SRC “Sibscan” on the Domodedovo airport (Moscow) The operator’s place 13 These pictures are made with System of Radiography Control (SRC) “Sibscan”. The hidden plastic knife and a dummy plastic gun 14 (made of fiberglass 4 mm thick) are clearly seen. The two pictures also show a piece of soap that imitates an explosive bar. Radiation dose is 1mkSv, which is equivalent to 10 minutes of flight background dose.