Developing a pipework scanner system using EDXRD

advertisement

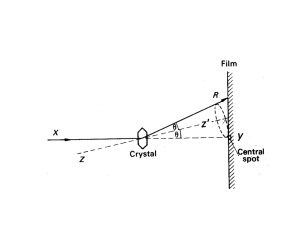

Developing a pipework scanner system using EDXRD Jamieson Lock Natural Science (Physics and Chemistry) Undergraduate College of Management and Technology Overview • • • • • • X-ray diffraction and its application Defects in pipework Previous work on project Project aims Initial work done towards project Problems and steps taken to overcome them • Where the project is going next College of Management and Technology X-ray diffraction nλ = 2d sin(θ/2) College of Management and Technology Applications • Inter-planar spacing of a microstructure – Phase transformations – Stresses – with high intensity X-rays • Amorphous structure still gives result – Security – explosives in luggage – Health – cancerous tissue • Locating possible defects in pipework College of Management and Technology Phases of steel • Ferrite – Body centred cubic • Austenite – Face centred cubic • Martensite – Body centred tetragonal • Chromium carbides – Simple orthorhombic College of Management and Technology Previous work • Research into ADXRD and EDXRD • EDXRD chosen – calculation heavy, but uses single detector and does not require monochromatic X-ray source • Tungsten collimator • Brittle fracture College of Management and Technology Source: Development of a prototype pipework scanning system using Energy Dispersive X-ray Diffraction - Bradley, Garrity, Jenneson, Vincent College of Management and Technology Previous error • Vertical ribbon beams • Large angular error possible • Systematic error – calculated to be 11.5º rather than 6.25º College of Management and Technology Initial state of project • New collimator • Had not been tested – Crack visible • Clamp system required College of Management and Technology Initial work • Clamp designs • EDM – Electrical discharge machining • Clamp fabrication • Operator training College of Management and Technology College of Management and Technology Set up • Holder and framework set up • Better than expected – Easily adjustable – No clips • Errors in previous work analysed College of Management and Technology Initial spectra 3000 2500 Count 2000 1500 1000 500 0 0 200 400 600 800 1000 Detector Channel Counts (over 5 minutes) 250 200 150 100 50 0 0 10 20 30 40 50 60 70 80 90 • Spectra taken before calibration • Heavy noise • Detector found to be broken • CdTe → CZT • Tungsten K lines • Still no diffraction peaks 100 Energy (KeV) College of Management and Technology Future work • • • • • • • Alignment problem Solve other problems Possible new collimator design Gain spectra for known samples Weld decay Martensitic structure Other phases/microstructures College of Management and Technology Summary • • • • • • • X-ray diffraction and uses Defects and associated phases Previous work – proof of concept Project details Work so far Current situation Future aims College of Management and Technology Dr David Garrity – Supervisor Dr Paul Chard-Tuckey – Group Manager Clare Scudder – Head of Nuclear Thank youDept. Dr Ian Giles – DE&S UDS Project Manager Anyplacement questions? Lewis Kiely – Fellow Student Samantha Morris – Placement Co-ordinator Dr Steve Andrews – Placement Tutor Paola Hayes – Health Physicist Terry McCarthy – Lab Assistant College of Management and Technology Extra slides College of Management and Technology Apparatus • • • • Varian 225 kV source Gulmay 3.2 kW supply Gulmay MP1 controller AmpTek XR-100T CdTe Detector – PX4 digital pulse processor • AmpTek XR-100T CdZnTe Detector – Pocket MCA College of Management and Technology First design College of Management and Technology Alignment problem: solutions A. Check horizontal alignment Still no peaks & Collimator broke B. Use old collimator with new holder Barely fits & Minimal flux C. Try original aluminium collimator To be arranged College of Management and Technology Spectra 250 Counts (over 5 minutes) 200 150 100 50 0 0 10 20 30 40 50 60 70 Energy (KeV) College of Management and Technology 80 90 100 Desired peaks (austenite) • • • • • D111 – 2.06 Å – 38.36 keV D200 – 1.78 Å – 44.39 keV D220 – 1.26 Å – 62.71 keV D113 – 1.07 Å – 73.90 keV D222 – 1.03 Å – 76.72 keV College of Management and Technology X-ray linearity test X-ray tube linearity test 400.00 350.00 Dose (mGy/min) 300.00 250.00 200.00 150.00 100.00 50.00 0.00 0.0 5.0 10.0 15.0 20.0 Tube current (mA) College of Management and Technology 25.0 100kV 30.0 150kV