Tall building with conventional outriggers

advertisement

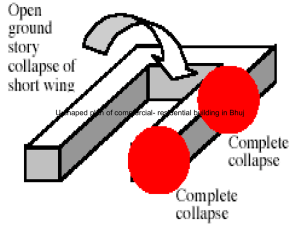

SEMINAR PRESENTATION ON THE EFFICIENT USE OF OUTRIGGER AND BELT TRUSS IN TALL BUILDINGS Submitted to MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY, JAIPUR In partial fulfillment of the requirement for the award of Degree of MASTER OF TECHNOLOGY IN STRUCTURAL ENGINEERING Under the supervision of: Dr. Ravindra Nagar Professor (Structural Engg. Deptt.) MNIT Jaipur Submitted By: Neeraj Agrawal M.Tech.(Structural Engineering) Student ID: 2010/PST/126 DEPARTMENT OF STRUCTURAL ENGINEERING, MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY JAIPUR, JAIPUR-302017 INTRODUCTION The outrigger and belt truss system is one of the lateral loads resisting system in which the external columns are tied to the central core wall with very stiff outriggers and belt truss at one or more levels. Tall building with conventional outriggers and belt truss Taken from S. Fawzia and T. Fatima The belt truss tied the peripheral column of building while the outriggers engage them with main or central shear wall. Strandard 3D view of Outrigger and belt truss Taken from S. Fawzia and T. Fatima The aim of this method is to reduce obstructed space compared to the conventional method. The floor space is usually free of columns and is between the core and the external columns, thus increasing the functional efficiency of the building. Exterior columns restrained the core wall from free rotation through outrigger arms. Outrigger and belt trusses, connect planar vertical trusses and exterior frame columns. Outrigger system can lead to very efficient use of structural materials by mobilizing the axial strength and stiffness of exterior columns. THE CONCEPT OF OUTRIGGER The great sailing ships of the past and present use outriggers to help resist the wind forces in their sails. Like the ship, the core in the tall building can be related to the mast of the ship, the outrigger acting like the spreaders and the exterior columns like the stays or shroud of the ship. THE USE OF OUTRIGGERS IN HIGH-RISE BUILDINGS TO CONTROL THE FORCES The incorporation of an outrigger which connects the two elements together provides a stiffer component which act together to resist the overturning forces. When an outrigger-braced building deflects under wind or seismic load, the outrigger which connects to the core wall and the exterior columns, makes the whole system to act as a unit in resisting the lateral load. TYPES OF OUTRIGGER TRUSS SYSTEM On the basis of connectivity of core to exterior columns, this system may be divided as in two types : 1. CONVENTIONAL OUTRIGGER CONCEPT 2. VIRTUAL OUTRIGGER CONCEPT CONVENTIONAL OUTRIGGER CONCEPT In the conventional outrigger concept, the outrigger trusses or girders are connected directly to shear walls or braced frames at the core and to columns located outboard of the core. Typically (but not necessarily), the columns are at the outer edges of the building. Tall building with conventional outriggers Taken from R. SHANKAR NAIR VIRTUAL OUTRIGGER CONCEPT In the “virtual” outrigger concept, the same transfer of overturning moment from the core to elements outboard of the core is achieved, but without a direct connection between the outrigger trusses and the core. The basic idea behind the virtual outrigger concept is to use floor diaphragms, which are typically very stiff and strong in their own plane. BELT TRUSSES AS VIRTUAL OUTRIGGERS The use of belt trusses as virtual outriggers avoids many of the problems associated with the use of conventional outriggers. The principle is the same as when belt trusses are used as virtual outriggers. Some fraction of the moment in the core is converted into a horizontal couple in the floors at the top and the bottom of the basement. Tall building with belt trusses as “virtual” outriggers Taken from R. SHANKAR NAIR ADVANTAGES OF USE OF BELT TRUSSES AS VIRTUAL OUTRIGGERS 1. There are no truss diagonals extending from the core to the exterior of the building. 2. The need to locate outrigger columns where they can be conveniently engaged by trusses extending from the core is eliminated. 3. The complicated eliminated. truss-to-core connection is 4. Differential shortening or settlement between the core and the outboard columns does not affect the virtual outrigger system since the floor diaphragms, though stiff in their own plane, are very flexible in the vertical, out-of-plane direction. Taken from R. SHANKAR NAIR FACTORS AFFECTING THE EFFECTIVENESS OF OUTRIGGER SYSTEM 1. The stiffness and location of the outrigger truss system. 2. The stiffness and location of the Belt truss system. 3. Geometry of the tall building. 4. Stiffness of the central core. 5. Floor-to-floor height of the tall building. Advantages of using Outrigger & Belt truss system 1. There are no trusses in the space between the core and the building exterior. 2. There are fewer constraints on the location of exterior columns. The need to locate large exterior columns where they can be directly engaged by outrigger trusses extending from the core is eliminated. 3. All exterior columns (not just certain designated outrigger columns) participate in resisting overturning moment. 4. The difficult connection of the outrigger trusses to the core is eliminated. 5. Core overturning moments can be reduced through the reverse moment applied to the core at each outrigger connection. 6. Exterior framing can consist of simple beam and column framing without the need for rigid-frametype connection, thus reducing the overall cost. 7. Reduction or elimination of uplift and net tension forces without the column and foundation system. PLAZA RAKYAT TOWER The 77-story Plaza Rakyat office tower in Kuala Lumpur, Malaysia, uses a concrete shear core, a concrete perimeter frame, exterior concrete belt walls at two levels, and a conventional outrigger system at the roof as the building’s lateral load-resisting system JIN MAO TOWER The 88-story Jin Mao Office, Hotel, observation, retail tower is in Shanghai, China. The tower is built around an octagon-shaped concrete shear wall core surrounded by 8 exterior composite super columns and 8 exterior steel columns. Three sets of 8 two-story high outrigger trusses connect the columns to the core at six of the floors to provide additional support TAIPEI 101 The 101-story TAIPEI-101 Office, Hotel, observation, retail tower is in Shanghai, China. The design achieves both strength and flexibility for the tower through the use of high-performance steel construction. Thirty-six columns support Taipei 101, including eight "mega-columns" packed with 10,000 psi (69 MPa) concrete. Every eight floors, outrigger trusses connect the columns in the building's core to those on the exterior. CHIFLEY TOWER The 42-story Chifley Tower Office, financial institutions, law firms and corporations tower is in Sydney, Australia. CONCLUSTIONS ON TALL BUILDINGS USING OUTRIGGER & BELT TRUSS 1. There are no trusses in the space between the core and the building exterior. 2. There are fewer constraints on the location of exterior columns. The need to locate large exterior columns where they can be directly engaged by outrigger trusses extending from the core is eliminated. 3. All exterior columns (not just certain designated outrigger columns) participate in resisting overturning moment. 4. The difficult connection of the outrigger trusses to the core is eliminated. 5. Complications caused by differential shortening of the core and the outrigger columns are avoided. REFERENCES 1. B.S. Taranath, Structural Analysis & Design of Tall Buildings. New York, Mc Graw Hill, 1998. 2. R. S. Nair, Belt Trusses and Basements as “Virtual” Outriggers for Tall Buildings. Engineering Journal / Fourth Quarter/ 1998. 3. Stafford Smith, B., Cruvellier, M., Nollet, M-J., and Mahyari, A. T., “Offset Outrigger Concept for Tall Buildings,” 4. P.S. Kian and F.T.Siahaan, The use of outrigger and belt truss system for high-rise concrete buildings. Dimensi Teknit Sipil, Volume 3, No1, Maret 2001, Page 36-41,ISSN1410-9530. 5. Smith, B. S., Coull, A. Tall Building Structures: Analysis and Design. John Wiley and Sons, Inc, New York. 6. S. Fawzia and T. Fatima, Deflection Control in Composite Building by Using Belt Truss and Outriggers Systems, Brisbane 4000, Australia.